A kind of pancreatic kininogenase and its preparation process

A technique for preparing pancreatic kininogenase and its preparation process, which is applied in the field of preparation of pancreatic kininogenase, can solve the problems that pancreatic kininogenase cannot be produced on a large scale, and achieves the advantages of small investment, short time consumption, and small loss of vitality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

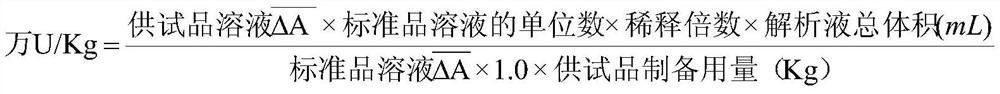

Image

Examples

Embodiment 1

[0059] Embodiment 1 A preparation process of pancreatic kininogenase, the specific steps are as follows:

[0060] (1) Frozen pig pancreas thawed

[0061] Frozen pig pancreas is thawed to a semi-thawed state on a thawing rack in a sterile thawing room, ensuring that the central temperature of the pancreas is ≤0°C, the temperature in the thawing room is 18°C, and the relative air humidity is ≥80% RH;

[0062] The thawing room is disinfected with ozone, and tools and appliances such as thawing racks are sterilized with hot alkaline water or chlorine dioxide disinfectant.

[0063] Raw materials should avoid contamination during transshipment and should not come into contact with pollution sources such as the ground (pallets and other tools and utensils should be sterilized in advance).

[0064] (2) Minced

[0065] The thawed porcine pancreas is shredded in an all-in-one cutting and shredding machine, and the temperature of the porcine pancreas pulp during the shredding process i...

Embodiment 2

[0103] Embodiment 2 A preparation process of pancreatic kininogenase, the specific steps are as follows:

[0104] (1) Frozen pig pancreas thawed

[0105] Frozen pig pancreas is thawed to a semi-thawed state on a thawing rack in a sterile thawing room, ensuring that the central temperature of the pancreas is ≤0°C, the temperature in the thawing room is 16°C, and the relative air humidity is ≥80%RH;

[0106] The thawing room is disinfected with ozone, and tools and appliances such as thawing racks are sterilized with hot alkaline water or chlorine dioxide disinfectant.

[0107] Raw materials should avoid contamination during transshipment and should not come into contact with pollution sources such as the ground (pallets and other tools and utensils should be sterilized in advance).

[0108] (2) Minced

[0109] The thawed porcine pancreas is shredded in an all-in-one cutting and shredding machine, and the temperature of the porcine pancreas slurry during the shredding process ...

Embodiment 3

[0147] Embodiment 3 A preparation process of pancreatic kininogenase, the specific steps are as follows:

[0148] (1) Frozen pig pancreas thawed

[0149] Frozen pig pancreas is thawed to a semi-thawed state on a thawing rack in a sterile thawing room, ensuring that the central temperature of the pancreas is ≤0°C, the temperature in the thawing room is 20°C, and the relative air humidity is ≥80% RH;

[0150] The thawing room is disinfected with ozone, and tools and appliances such as thawing racks are sterilized with hot alkaline water or chlorine dioxide disinfectant.

[0151] Raw materials should avoid contamination during transshipment and should not come into contact with pollution sources such as the ground (pallets and other tools and utensils should be sterilized in advance).

[0152] (2) Minced

[0153] The thawed porcine pancreas is shredded in an all-in-one cutting and shredding machine, and the temperature of the porcine pancreas slurry during the shredding process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com