A non-contact graphite boat

A graphite boat, non-contact technology, applied in the field of graphite boat, can solve the problems of scratch coating and unevenness of silicon wafers, and achieve the effects of avoiding scratches, avoiding uneven coating, and improving the appearance qualification rate and photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

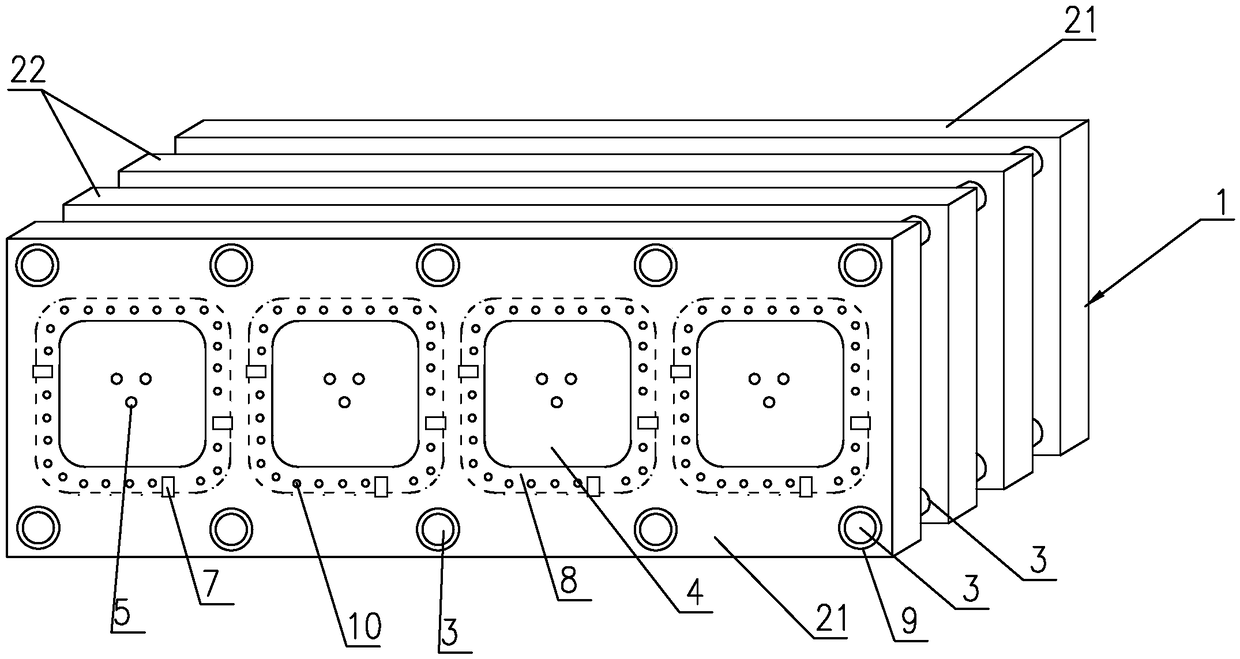

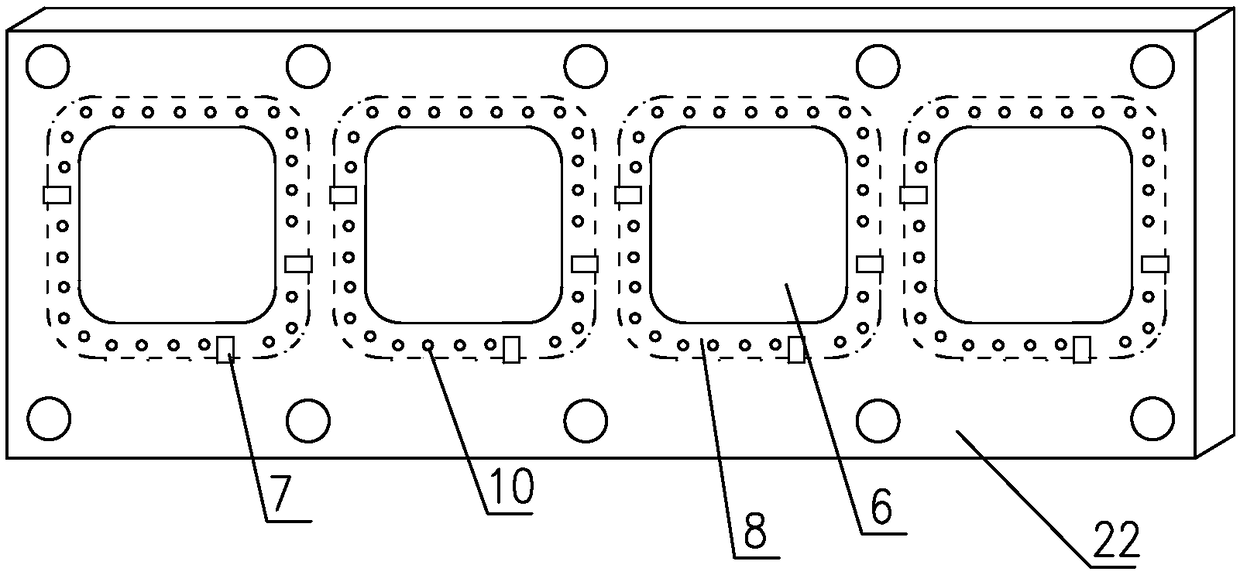

[0022] Such as figure 1 and 2 As shown, it is a kind of non-contact insert graphite boat 1 of the present invention, and it is mainly made up of insulating rod and several unit boats arranged in the horizontal direction, and the unit boat is the plate-shaped body that vertically arranges, and the unit boat The number is 2-50. In this embodiment, there are four unit boats, there are gaps between adjacent unit boats, and the distance between adjacent unit boats is 5-50m. Insulating rod adopts ceramic rod 3, and ceramic rod 3 runs through at the periphery of each unit boat and all unit boats are connected and fixed together, and the two ends of ceramic rod 3 are positioned on the outer surface of unit boat 21 on both sides by The fixing part 9 is fixed. The inner and outer surfaces of the unit boats 21 located at the two outer sides are provided with some grooves 4 that are identical in shape to the silicon wafers and whose size is smaller than the size of the silicon wafers. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com