Wearable thermoelectric generator with hollow structure base and manufacture method thereof

A thermoelectric generator and hollow structure technology, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric devices, thermoelectric devices using only Peltier or Seebeck effect, etc. problems, to broaden the application occasions, improve the use occasions, and the effect of accurate position correspondence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

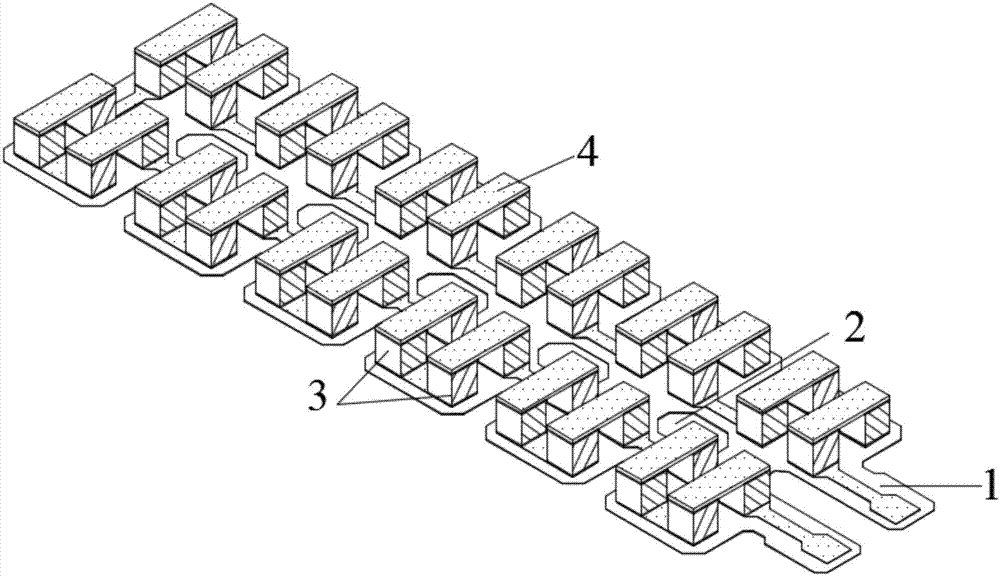

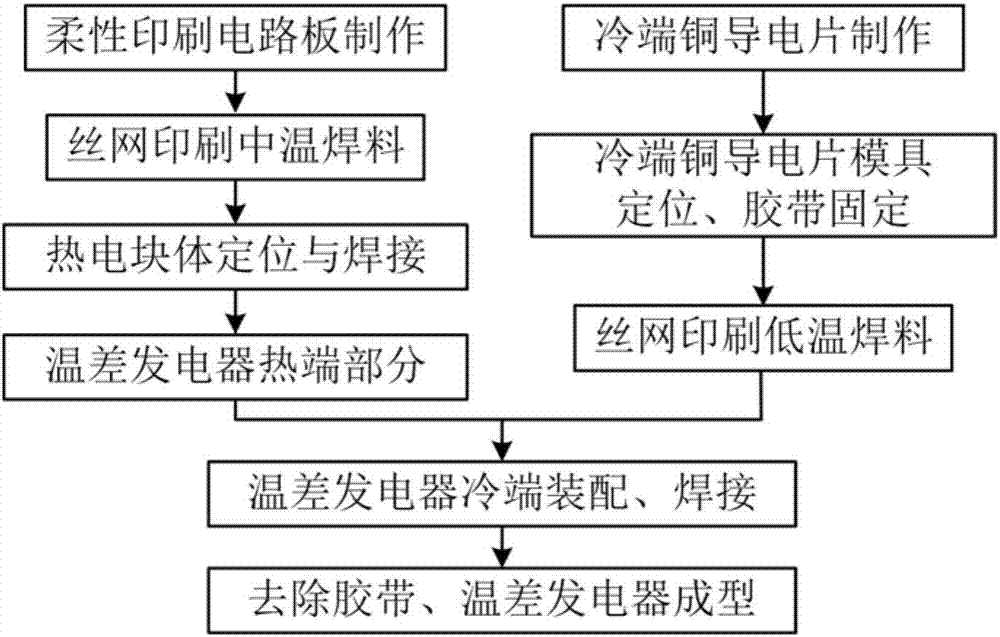

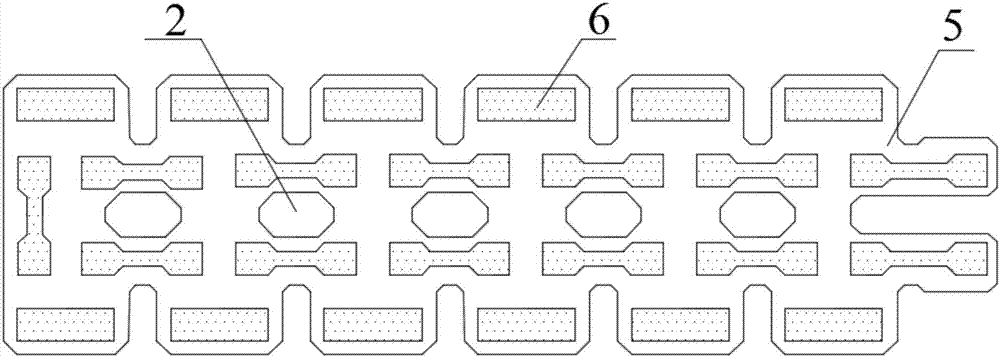

[0039] Such as figure 1 As shown, the present invention sequentially includes a flexible printed circuit board 1 with a hollow structure 2, a thermoelectric block array 3, and a cold-end copper conductive sheet 4 from the wearing surface; The upper layer of the copper electrode of the circuit board 1 is connected, and the cold end surface of the thermoelectric block array 3 is connected to the lower layer of the cold end copper conductive sheet 4 through low-temperature solder; the thermoelectric block array 3 has m rows, m is an even number, and m≥2, each The row contains four or more pairs of P-type and N-type thermoelectric blocks with the same size and number. The thermoelectric block array forms a series or series-parallel structure through the copper electrodes of the hot-end flexible printed circuit board and the cold-end copper conductive sheets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com