A kind of preparation method of ceramic composite membrane

A ceramic composite membrane and ceramic particle technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of long preparation period, poor membrane adhesion, and high energy consumption, and achieve easy operation and stability. Good performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

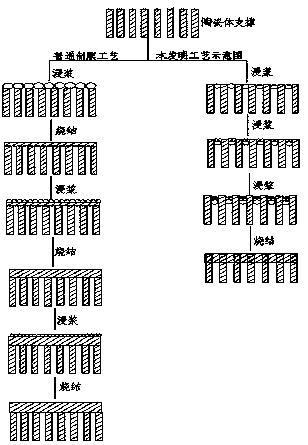

[0011] Such as figure 1 Shown, the present invention is a kind of preparation method of ceramic composite membrane, and its steps are:

[0012] (1) Select ceramic particles with a particle size of 1 / 2-2 / 3 of the average surface pore size of the porous ceramic support, and add 0.05% to 20% by weight to the organic solvent or water based on the quality of the solvent or water used , and then based on the quality of the solvent or water, sequentially add 0.1% to 5% dispersant and 1% to 5% thickener in mass percentage to prepare a uniformly dispersed and stable suspension of ceramic particles;

[0013] (2) Immerse the cleaned porous ceramic support in the slurry prepared in step (1), and absorb the ceramic particles in the slurry in the pores on the surface of the porous ceramic support by using negative pressure; the pumped The negative pressure is 0.01~0.1MPa, and the soaking time is 10~300s. After soaking, wash off the excess ceramic particles attached to the surface;

[0014...

Embodiment 1

[0022] Example 1: Porous α-Al 2 o 3 Sheet-like ceramics are used as supports with a pore size of 3 μm.

[0023] (1) Using water as a solvent, based on water quality, add 1.7μm TiO with mass percentages of 2%, 0.5% and 1% respectively 2 Granules, polyethyleneimine, ethylcellulose and sodium carboxymethylcellulose (1:1wt) mixture, where polyethyleneimine is the dispersant, ethylcellulose and sodium carboxymethylcellulose (1:1wt) The mixture is a thickener;

[0024] (2) Immerse the cleaned porous ceramic support into the slurry prepared in step (1), and use negative pressure to remove the TiO in the slurry 2 Particles are adsorbed in the pores on the surface of the porous ceramic support; the negative pressure is 0.03MPa, the soaking time is 40s, and the excess Ti particles attached to the surface are cleaned after soaking;

[0025] (3) Select TiO with a particle size of 1.1 μm 2 Particles, repeat step (1), put the ceramic support containing Ti particles in step (2) into the...

Embodiment 2

[0028] Example 2: A porous tubular titanium oxide ceramic is used as a support body, and its pore diameter is 8 μm.

[0029] (1) With absolute ethanol as the solvent, based on the mass of absolute ethanol, 10%, 2% and 3% of 7.3μm Al 2 o 3 Particles, a mixture of polyethylene glycol, ethyl cellulose and polyvinyl alcohol (1:1wt), in which polyethyleneimine is a dispersant, and a mixture of ethyl cellulose and sodium carboxymethylcellulose (1:1wt) is an enhancer Thickener;

[0030] (2) Immerse the cleaned porous ceramic support into the slurry prepared in step (1), and use negative pressure to remove the Al in the slurry 2 o 3 Particles are adsorbed in the pores on the surface of the porous ceramic support; the negative pressure is 0.1MPa, and the soaking time is 80s. After soaking, the excess Al attached to the surface is cleaned. 2 o 3 particle;

[0031] (3) Select Al with a particle size of 3.5 μm 2 o 3 Particles, repeat step (1), the step (2) containing Al 2 o 3 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com