A kind of preparation method of magnetic adsorption material

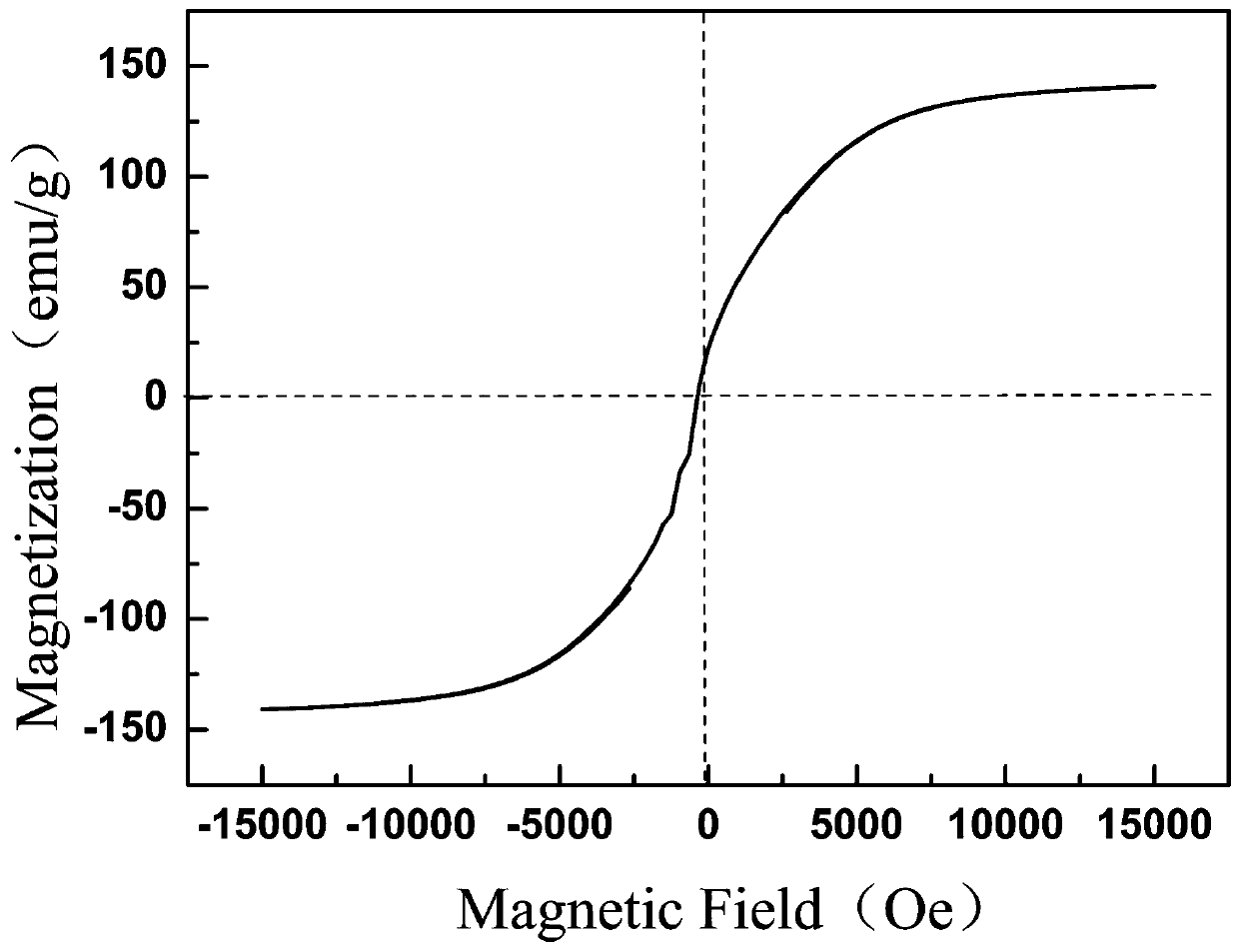

A magnetic adsorption material and magnetic separation technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as lack of superparamagnetism, easy sedimentation in the adsorption process, complicated preparation process, etc., to achieve Excellent magnetic adsorption separation performance, simple preparation method and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

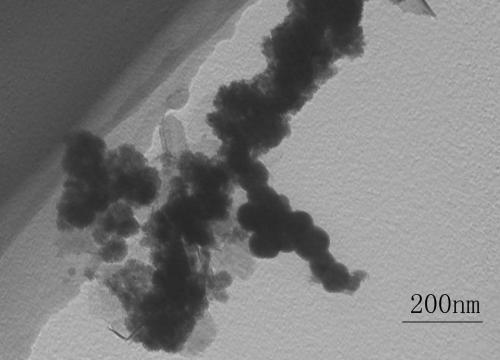

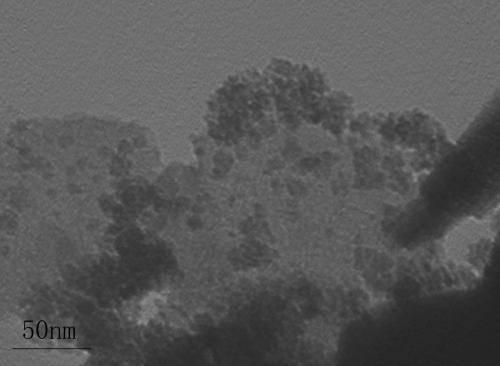

[0034] 1. Preparation of magnetic adsorption materials

[0035] (1) Fe 0 Preparation of iron powder (reduced iron powder): 0.5 mmol of FeSO 4 7H 2 O was dissolved in 10 mL of deionized water to form a transparent solution, labeled as solution 1; similarly, 1 mmol NaBH 4 Dissolved in 10 mL deionized water, marked as solution 2; solution 2 was added dropwise to solution 1 at a rate of 20 s / mL, and after the generation of bubbles stopped, the resulting black solid was collected by magnetic separation, and finally in Repeatedly washing 3 times in deionized water, Fe can be obtained 0 iron powder.

[0036] (2) Chitosan-coated Fe 3 o 4 Preparation: Fe obtained in step 1 0 Add iron powder, 0.2g chitosan and 1.5mmol NaOH to 20 mL deionized water to dissolve and disperse, keep the pH of the mixed solution at 7, keep it under vigorous magnetic stirring for 20min; transfer the obtained mixed solution to a hydrothermal kettle , kept at 80°C for 60min; the product after hydrotherma...

Embodiment 2

[0043] 1. Preparation of magnetic adsorption materials

[0044] (1) Fe 0 Preparation of iron powder (reduced iron): 0.9 mmol FeSO 4 7H 2 O was dissolved in 10 mL deionized water to form a transparent solution, labeled as solution 1; similarly, 1.5 mmol NaBH 4 Dissolved in 10 mL of deionized water, marked as solution 2; solution 2 was added dropwise to solution 1, and after the generation of bubbles stopped, the resulting black solid was collected by magnetic separation, and finally washed repeatedly in deionized water for 6 times, can get Fe 0 iron powder.

[0045] (2) Chitosan-coated Fe 3 o 4 Preparation: the prepared Fe 0 Add iron powder, 0.5 g chitosan and 2 mmol NaOH to 20 mL deionized water to dissolve and disperse, keep the pH of the mixed solution at 8, and keep it under vigorous magnetic stirring for 20 min; transfer the obtained mixed solution to a hydrothermal kettle , kept at 100°C for 120 min; the product after hydrothermal reaction was collected by magneti...

Embodiment 3

[0051] 1. Preparation of magnetic adsorption materials

[0052] (1) Fe 0 Preparation of iron powder (reduced iron): 0.8 mmol FeSO 4 7 hours 2 O was dissolved in 10 mL of deionized water to form a transparent solution, labeled as solution 1; similarly, 1.4 mmol NaBH 4 Dissolve in 10 mL of deionized water and mark it as solution 2; add solution 2 to solution 1 dropwise at 15 s / mL; after the generation of bubbles stops, collect the obtained black solid by magnetic separation, and finally repeat in deionized water Wash 5 times to get Fe 0 iron powder.

[0053] (2) Chitosan-coated Fe 3 o 4 Preparation: the prepared Fe 0 Add iron powder, 0.4g chitosan and 1.5mmol NaOH to 20 mL deionized water to dissolve and disperse, keep the pH of the mixed solution at 7, keep it under vigorous magnetic stirring for 20min; transfer the obtained mixed solution to a hydrothermal kettle , kept at 90°C for 100 min; the product after hydrothermal reaction was collected by magnetic separation, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com