Advanced treatment method of anaerobic effluent of cassava alcoholic waste liquor

A technology of anaerobic effluent and cassava alcohol, which is applied in the field of sewage purification and treatment, can solve the problem of high content of soluble organic matter, and achieve the effects of improving treatment efficiency and energy recovery rate, good application and research prospects, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

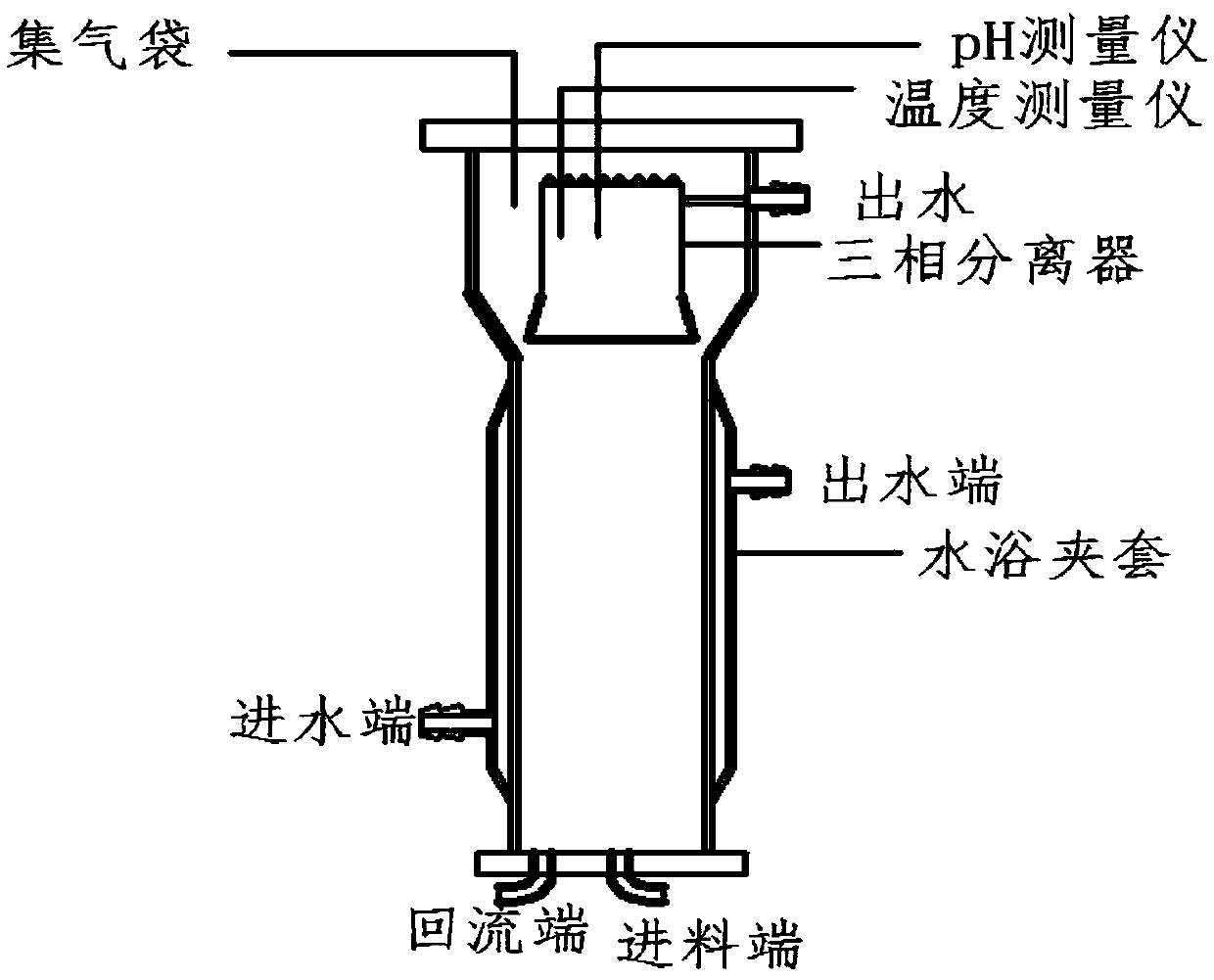

[0033] use figure 1 The upflow anaerobic sludge bed UASB reactor device shown is made of all glass, with a volume of 9.5L and an actual effective reaction volume of 7.2L. The reaction temperature is 35°C, the influent water enters from the bottom of the reactor through a pump, the biogas generated by the reaction is separated by a three-phase separator, and is discharged from the gas discharge pipe to the gas collection bag for collection, and the effluent and influent water are refluxed at a ratio of 2:1. The outside of the reactor is a glass interlayer, and the water bath heating method is used to maintain the temperature at 35°C.

Embodiment 2

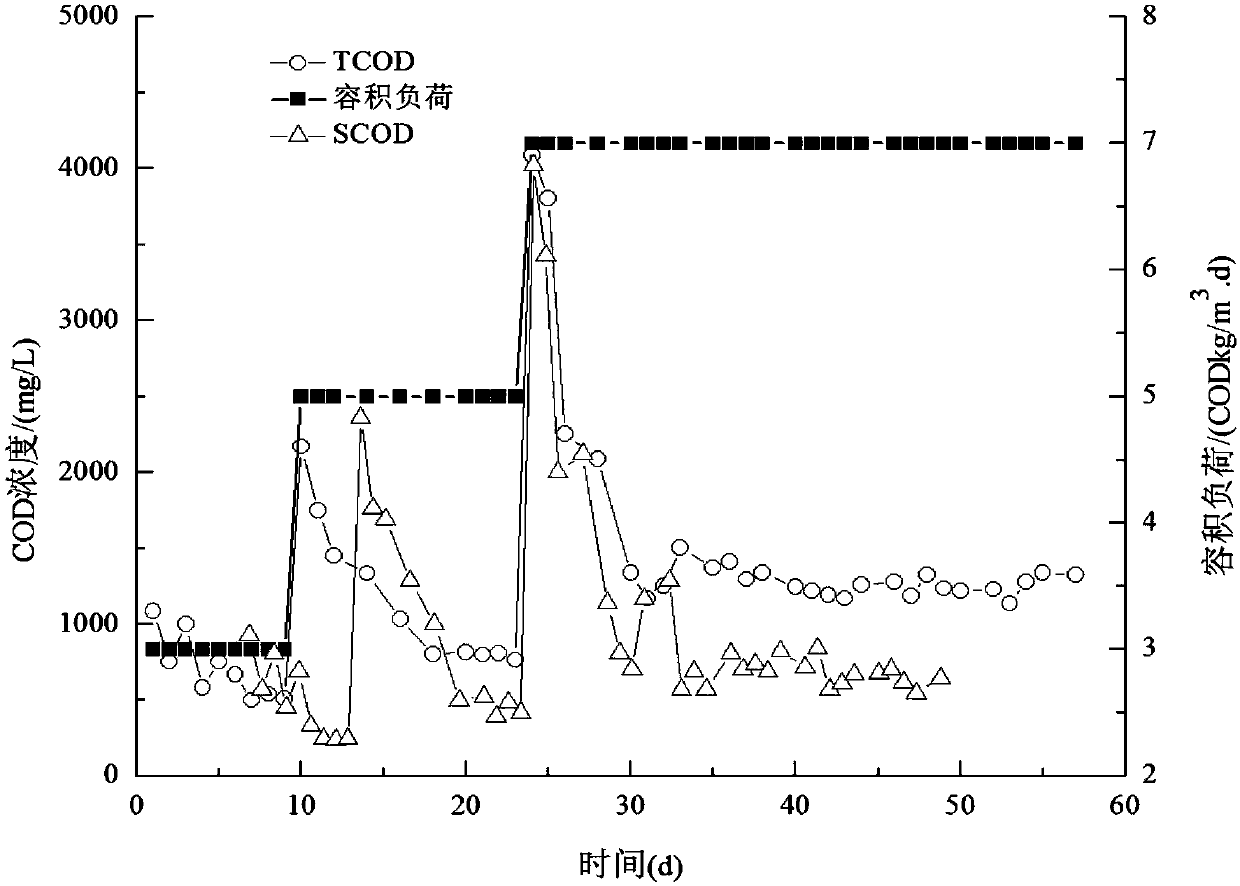

[0034] Variation of UASB reactor effluent COD under different operating conditions of embodiment 2

[0035] The operating performance of the UASB reactor is as follows: figure 2 shown. After being treated in the first-stage CSTR anaerobic reactor, the effluent is diluted according to the set corresponding hydraulic retention time and volume load, and then enters the UASB reactor for anaerobic fermentation using a pump. At 3kgCOD / (m 3 .d) Operate under load for 10 days, increase to 5kgCOD / (m 3 .d) Run for 15 days, then increase to 7kgCOD / (m 3 .d) Run 33d. After nearly 60 days of treatment, the final reactor operating load is 7kgCOD / m 3 .d, the concentrations of TCOD and SCOD in the effluent water were 1327.9 and 551.2 mg / L, respectively, and the removal rate of TCOD reached 83.0% to 84.1%. During the treatment process, the concentration of organic matter in the effluent increases with the increase of the influent volume load.

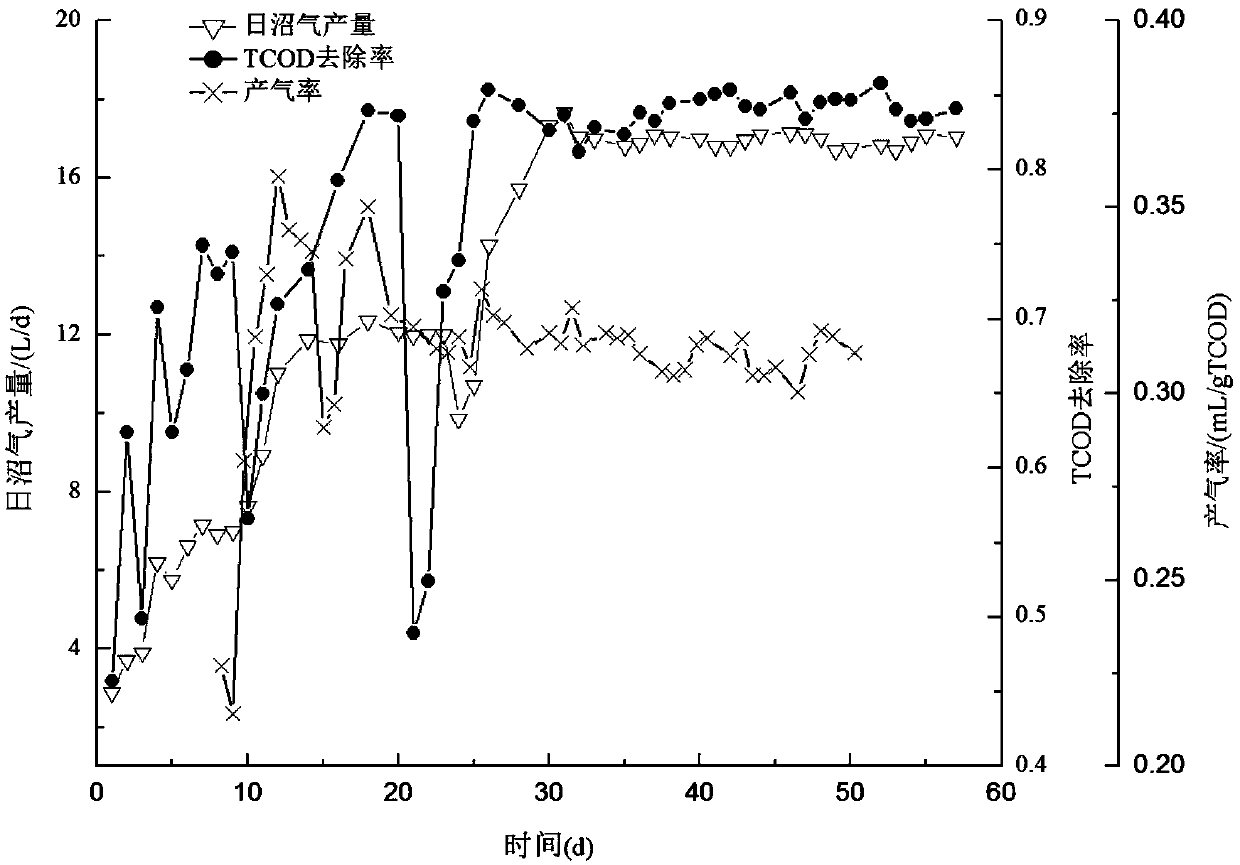

[0036] Such as image 3 As shown, the dail...

Embodiment 3

[0040] Example 3 Kinetic model of CSTR anaerobic reaction biogas production rate under different volume loads

[0041] The operating parameters of the reactor are controlled according to the following kinetic model:

[0042] The establishment of the kinetic model is based on the conservation of materials, then:

[0043]

[0044] In the above formula:

[0045] V R is the volume of the reactor (L); m o is the amount of material added (L / d); C 0 is the concentration of organic matter in the feed material (g / L); c is the concentration of organic matter in the reactor (g / L); r(c) is the rate at which the substrate is digested (g / L.d); y is the unit raw material Gas production rate (L / gTCOD); y m is the maximum unit raw material gas production rate (L / gTCOD);

[0046] According to the first order reaction kinetics:

[0047]

[0048] Among them, k is the first order reaction rate (d -1) .

[0049] According to HRT=m 0 .VR, under steady state conditions, can be obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com