Fischer-Tropsch synthetic wastewater treatment device and treatment method for Fischer-Tropsch synthetic wastewater

A technology for Fischer-Tropsch synthesis wastewater and treatment device, which is applied in the field of coal liquefaction and can solve the problems of difficulty in Fischer-Tropsch synthesis of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

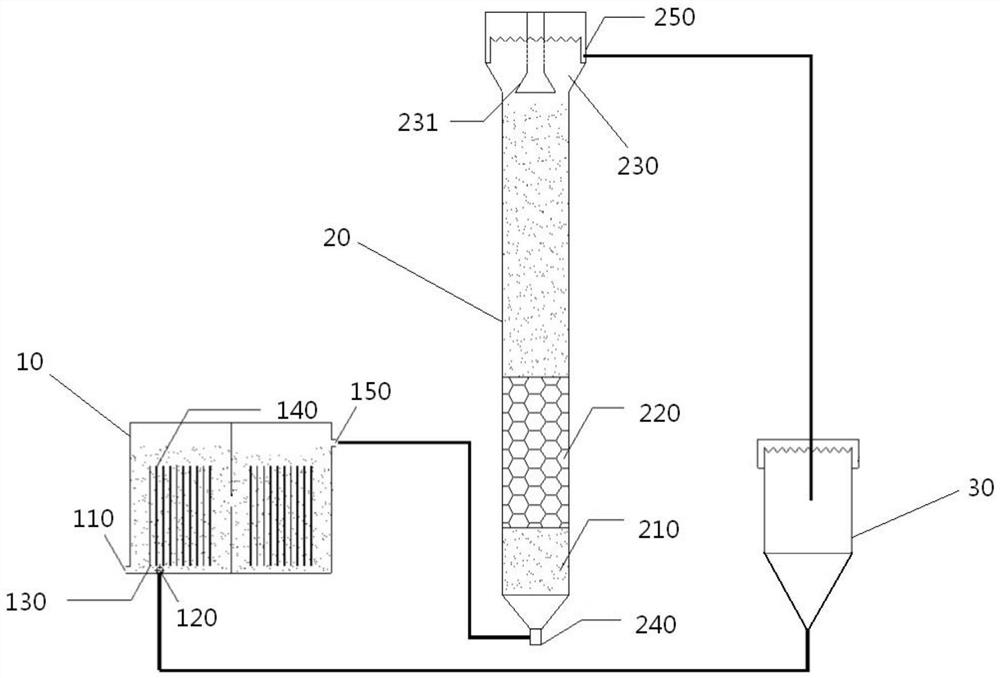

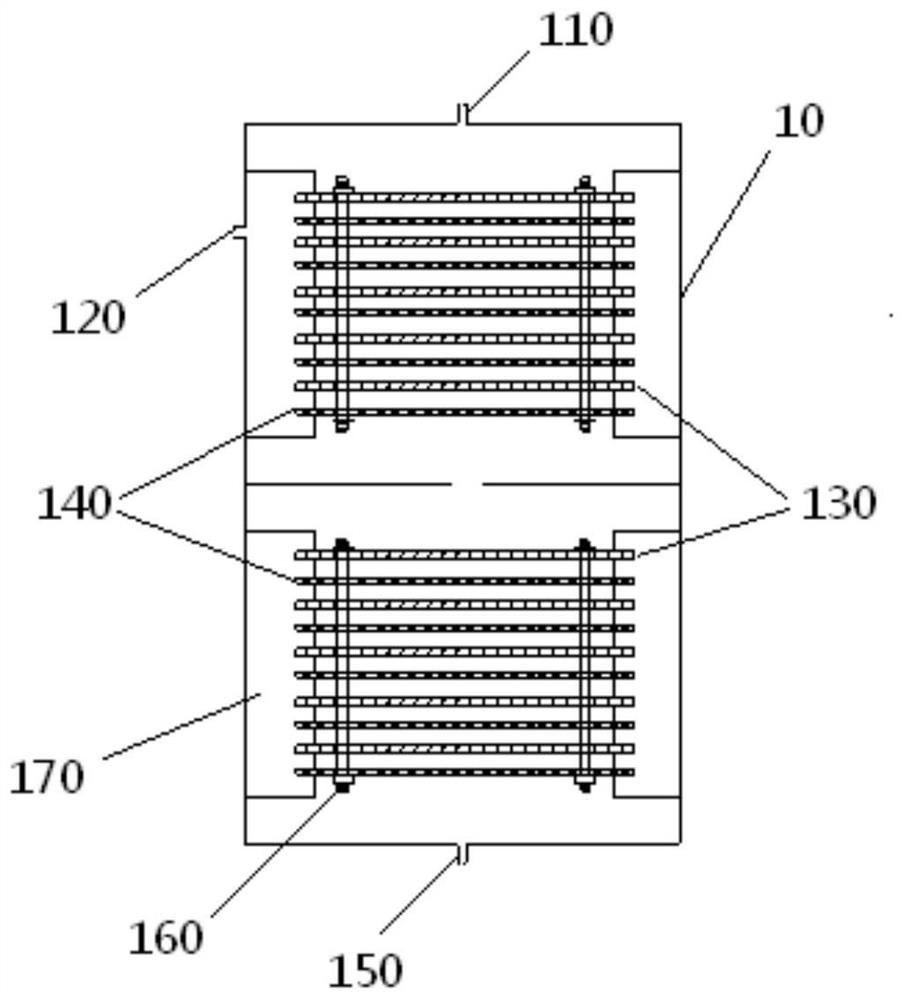

Method used

Image

Examples

Embodiment 1

[0055] Under the condition that the influent CODcr is 30000-36000mg / L and the pH value is 3.0, the residence time of the microbial electrolytic cell and the anaerobic reactor are controlled to be 4h and 4d respectively, and the current density of the microbial electrolytic cell is maintained at 15mA / cm2. The reflux ratio of the secondary settling tank is 250%. After the Fischer-Tropsch synthetic wastewater treatment plant has been running stably for 60 days, the average removal rate of CODcr in the microbial electrolytic cell is 6%, but organic alcohol and organic acid (carbon chain > 2) to acetic acid The conversion rate is stable above 90%, the removal of CODcr by the anaerobic reactor is stable above 75%, and the CODcr in the anaerobic effluent is 5700mg / L~6480mg / L, which can be effectively degraded and removed through the anaerobic stage, greatly reducing the subsequent good The load of the aerobic biological sludge method saves the cost of subsequent aerobic aeration biode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com