Energy-saving sheet material for park road and preparation method of energy-saving sheet material

A board and road technology, applied in the field of energy-saving boards for park roads and its preparation, can solve the problems of easy freezing of park road boards, damage to the structure of road boards, affecting people's comfort, etc. Thermal conductivity, effect of delaying cement hydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

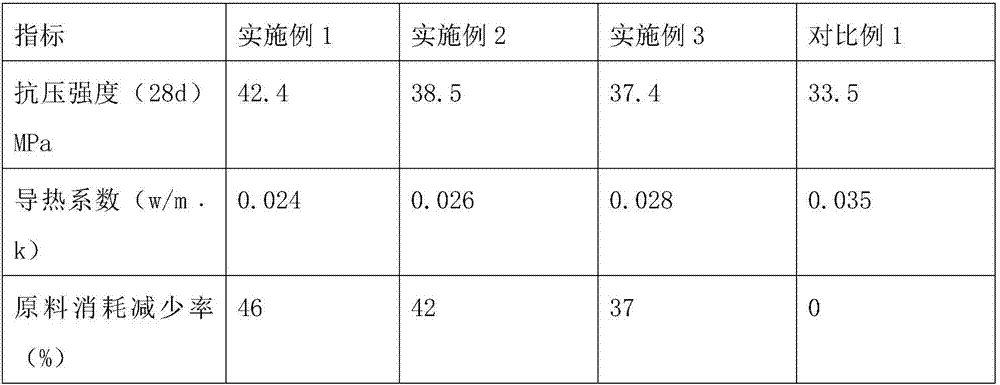

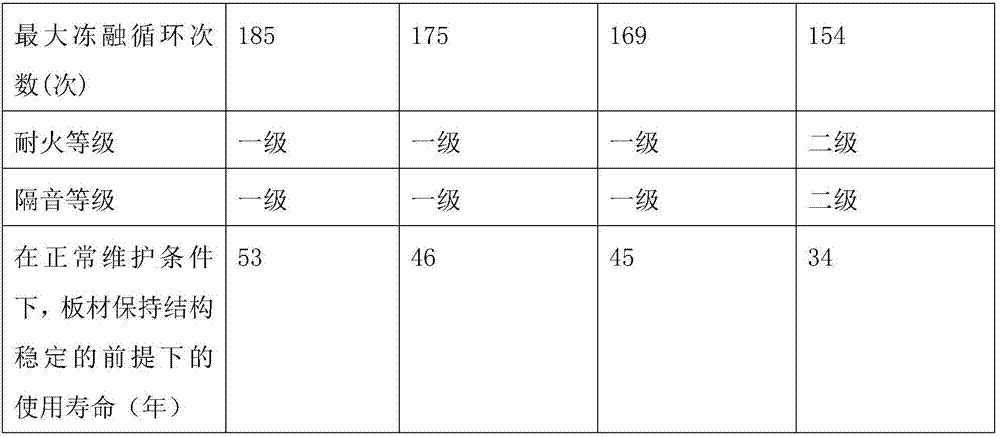

Embodiment 1

[0039] An energy-saving board for park roads, comprising the following raw materials in parts by weight: 17kg of quartz sand, 32.5kg of gravel, 25kg of cement, 22.5kg of waste gypsum board, 1.35kg of glass fiber, 12.5kg of construction waste plastic, waste phenolic foam 27.5kg, 18kg of heat insulation cotton, 17.5kg of fly ash, 12.5kg of ceramic waste, 0.7 parts of retarder, 1.2kg of water reducing agent and 5kg of water.

[0040] The energy-saving board for park roads prepared under the raw material formula has reached the best in terms of energy saving and environmental protection, compressive strength, durability, frost resistance, fire resistance, and sound and heat insulation.

[0041] Waste gypsum boards, construction waste plastics, waste phenolic foam, ceramic waste and fly ash are added to the raw materials. These construction wastes and industrial wastes have solved the current problems of large consumption of boards in park roads and the inability to reuse waste, ach...

Embodiment 2

[0057] An energy-saving board for park roads, comprising the following raw materials in parts by weight: 14kg of quartz sand, 30 parts of crushed stone, 20kg of cement, 20kg of waste gypsum board, 1.2kg of glass fiber, 10kg of construction waste plastic, 25kg of waste phenolic foam, 15kg of hot cotton, 15kg of fly ash, 10kg of ceramic waste, 0.6kg of retarder, 0.8kg of water reducing agent and 3kg of water.

[0058] Waste gypsum boards, construction waste plastics, waste phenolic foam, ceramic waste and fly ash are added to the raw materials. These construction wastes and industrial wastes have solved the current problems of large consumption of boards in park roads and the inability to reuse waste, achieving energy saving environmental protection purposes.

[0059] Waste gypsum board has the characteristics of light weight, high compressive strength, sound and heat insulation and fire resistance.

[0060] Construction waste plastics have the characteristics of stable chemica...

Embodiment 3

[0074] An energy-saving board for park roads, including the following raw materials in parts by weight: 20kg of quartz sand, 35kg of gravel, 30kg of cement, 25kg of waste gypsum board, 1.5kg of glass fiber, 15kg of construction waste plastic, 30kg of waste phenolic foam, heat insulation Cotton 21kg, fly ash 20kg, ceramic waste residue 15kg, retarder 0.8kg, water reducing agent 1.6kg and water 7kg.

[0075] Waste gypsum boards, construction waste plastics, waste phenolic foam, ceramic waste and fly ash are added to the raw materials. These construction wastes and industrial wastes have solved the current problems of large consumption of boards in park roads and the inability to reuse waste, achieving energy saving environmental protection purposes.

[0076] Waste gypsum board has the characteristics of light weight, high compressive strength, sound and heat insulation and fire resistance.

[0077] Construction waste plastics have the characteristics of stable chemical properti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com