Treating method for androstenedione fermented wastes and application of recovered materials

A technology of androstenedione and a processing method, applied in the field of androstenedione fermentation production, can solve the problems of easily polluting the environment, occupying the space of factories and enterprises, restricting the development of enterprises, etc., achieving simple operation, reducing production costs, and increasing enterprise benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

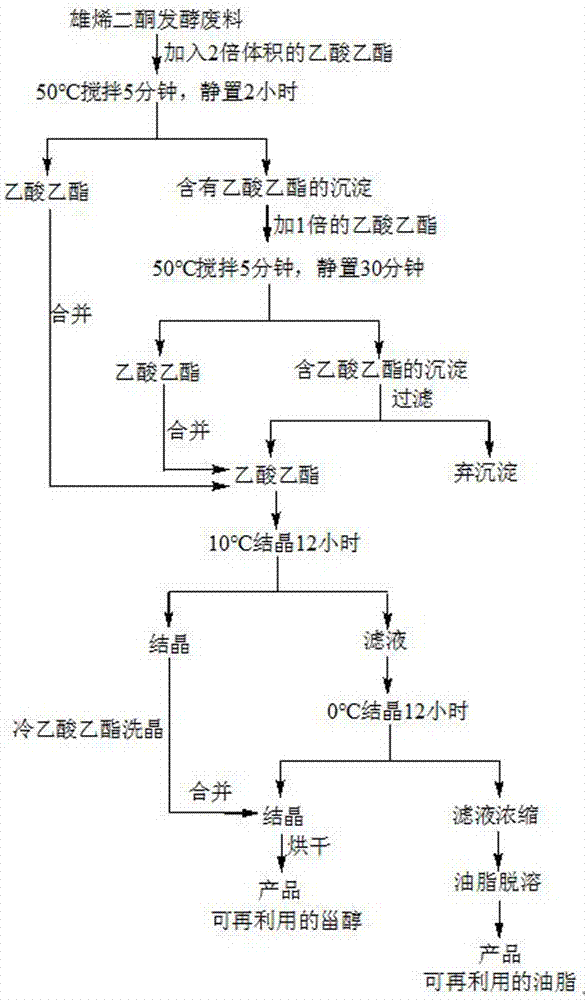

[0033] The processing method of androstenedione fermentation waste, the steps are as follows:

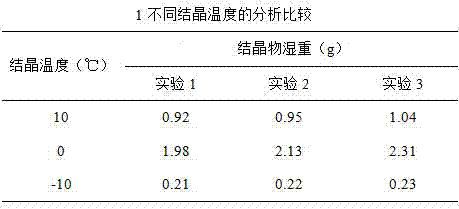

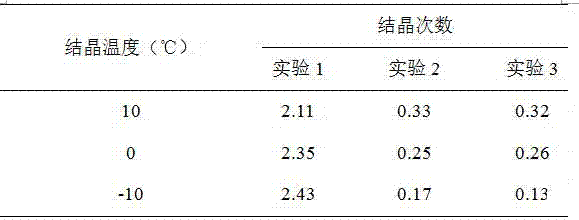

[0034] 1) Add ethyl acetate solvent to the androstenedione fermentation waste according to the solid-liquid ratio of 1:2, and stir for 5 minutes in a water bath at 50°C, then let it stand for 2 hours, and take the ethyl acetate phase of the upper layer for use; After adding an equal volume of ethyl acetate solvent to the phase, let it stand at 50°C for 30 minutes, take the upper phase of ethyl acetate for use, and at the same time filter the lower phase to obtain a filtrate, and mix it with the above-mentioned ethyl acetate phase to obtain a mixed solution. The filter residue is discarded;

[0035] 2) The mixed solution was crystallized at 10°C and 0°C for 12 hours successively; after each crystallization, the crystals were filtered and washed with ethyl acetate solvent to obtain sterol crystals with a purity of 95%; the obtained filtrate was concentrated and degreased Melt, that i...

Embodiment 2

[0037] The processing method of androstenedione fermentation waste, the steps are as follows:

[0038] 1) Add ethyl acetate solvent to the androstenedione fermentation waste according to the solid-liquid ratio of 1:2, and stir for 5 minutes in a water bath at 60°C, then let it stand for 2 hours, and take the ethyl acetate phase of the upper layer for use; After adding an equal volume of ethyl acetate solvent to the phase, let it stand at 60°C for 30 minutes, take the upper phase of ethyl acetate for use, and at the same time filter the lower phase to obtain a filtrate, and mix it with the above ethyl acetate to obtain a mixed solution. The filter residue is discarded;

[0039] 2) The mixed solution was crystallized at 10°C and 0°C for 12 hours successively; after each crystallization, the crystals were filtered and washed with ethyl acetate solvent to obtain sterol crystals with a purity of 95%; the obtained filtrate was concentrated and degreased Melt, that is, fat.

Embodiment 3

[0041] The processing method of androstenedione fermentation waste, the steps are as follows:

[0042] 1) Add ethyl acetate solvent to the androstenedione fermentation waste according to the solid-liquid ratio of 1:3, and stir for 5 minutes in a water bath at 50°C, then let it stand for 2 hours, and take the ethyl acetate phase of the upper layer for use; After adding an equal volume of ethyl acetate solvent to the phase, let it stand at 60°C for 30 minutes, take the upper phase of ethyl acetate for use, and at the same time filter the lower phase to obtain a filtrate, and mix it with the above ethyl acetate to obtain a mixed solution. The filter residue is discarded;

[0043] 2) The mixed solution was crystallized at 10°C and 0°C for 12 hours successively; after each crystallization, the crystals were filtered and washed with ethyl acetate solvent to obtain sterol crystals with a purity of 95%; the obtained filtrate was concentrated and degreased Melt, that is, fat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com