A kind of preparation method of multifunctional polycarboxylate water reducer

A multifunctional, polycarboxylic acid technology, used in the field of concrete admixtures in the building materials industry, can solve the problem of no introduction of slump retention performance, and achieve the effects of high water reduction rate, improved hydration degree, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention provides a kind of preparation method of multifunctional polycarboxylate water reducer, comprising the following steps:

[0020] 1. Selection of raw materials: 180 parts by mass of isopentenyl polyoxyethylene ether, 10 parts by mass of fumaric acid, 7 parts by mass of acrylic acid, 20-25 parts by mass of hydroxyethyl acrylate, 1-2 parts by mass of acrylamide methylpropanesulfonic acid 1-2 parts by mass of acrylamide, 1.5 parts by mass of oxidizing agent, 1 part by mass of reducing agent, 0.8 parts by mass of chain transfer agent, 5 parts by mass of sodium hydroxide, and 338.7-349.2 parts by mass of water.

[0021] 2. Add isopentenyl polyoxyethylene ether and fumaric acid into 120 parts by mass of water, stir to dissolve, then add an oxidant, and stir to obtain a uniform solution.

[0022] 3. Add acrylic acid, hydroxyethyl acrylate, acrylamidomethylpropanesulfonic acid, and acrylamide to 20 parts by mass of water to obtain 1# solution; add reducing ...

Embodiment 1-4

[0033] Examples 1-4 took materials according to the proportions in Table 1, and prepared four multifunctional polycarboxylate water reducers according to steps 1-3 of the present invention.

[0034] Table 1: Specific Implementation Material Proportion Unit / g

[0035]

Embodiment 5

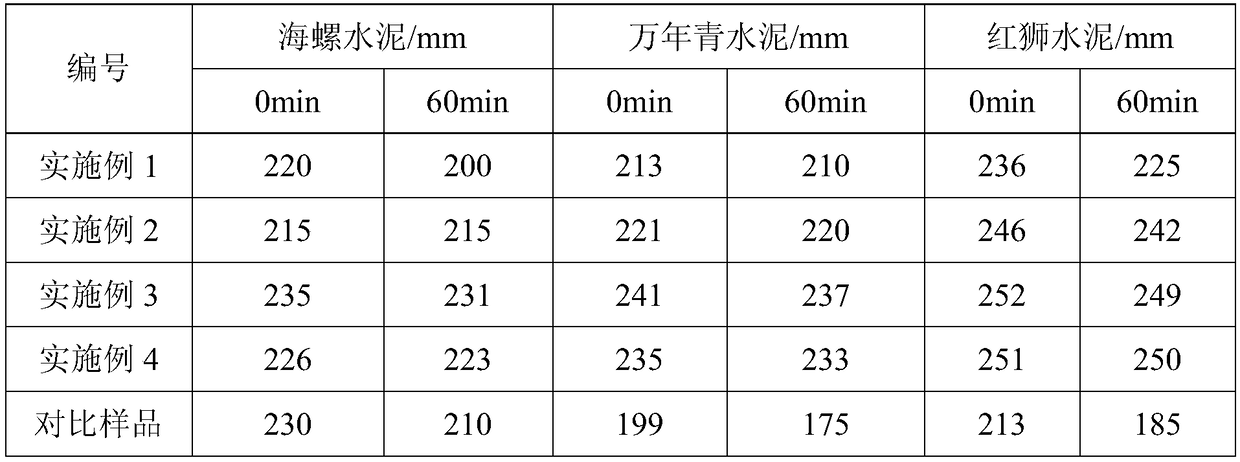

[0037] The multi-functional polycarboxylate water-reducer prepared in Examples 1-4 of the present invention and the comparative sample were tested for the fluidity of cement paste, and the multi-functional polycarboxylate water-reducer prepared in Examples 1-4 of the present invention was replenished with water A transparent liquid with a solid content of about 40% was obtained. The comparative sample is a commercially available early-strength superplasticizer with a solid content of 40%.

[0038] Refer to GB / T8077-2000, 300g of cement, 87g of water, 0.6g of mixing amount, detailed test data are shown in Table 2:

[0039] Table 2: Fluidity test of clean pulp

[0040]

[0041] It can be seen from Table 2 that the polycarboxylate superplasticizer of the present invention has better adaptability at a lower dosage, and the initial embodiment 4 can adapt to various cements and has better slump-preserving effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com