A method for smelting zinc-copper-titanium master alloy using self-dissolving copper bell jar

An intermediate alloy, zinc-copper-titanium technology, which is applied in the field of smelting zinc-copper-titanium intermediate alloys using self-dissolving copper bell jars, can solve the problems of oxidation, burning loss, and insufficient depth of titanium and copper elements, so as to reduce burning loss and lighten the The effect of stirring degree and specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) First place the 20# graphite crucible in the coke furnace, then put 32.8 kg of zinc ingot into the crucible and heat to 480°C for melting to obtain zinc liquid;

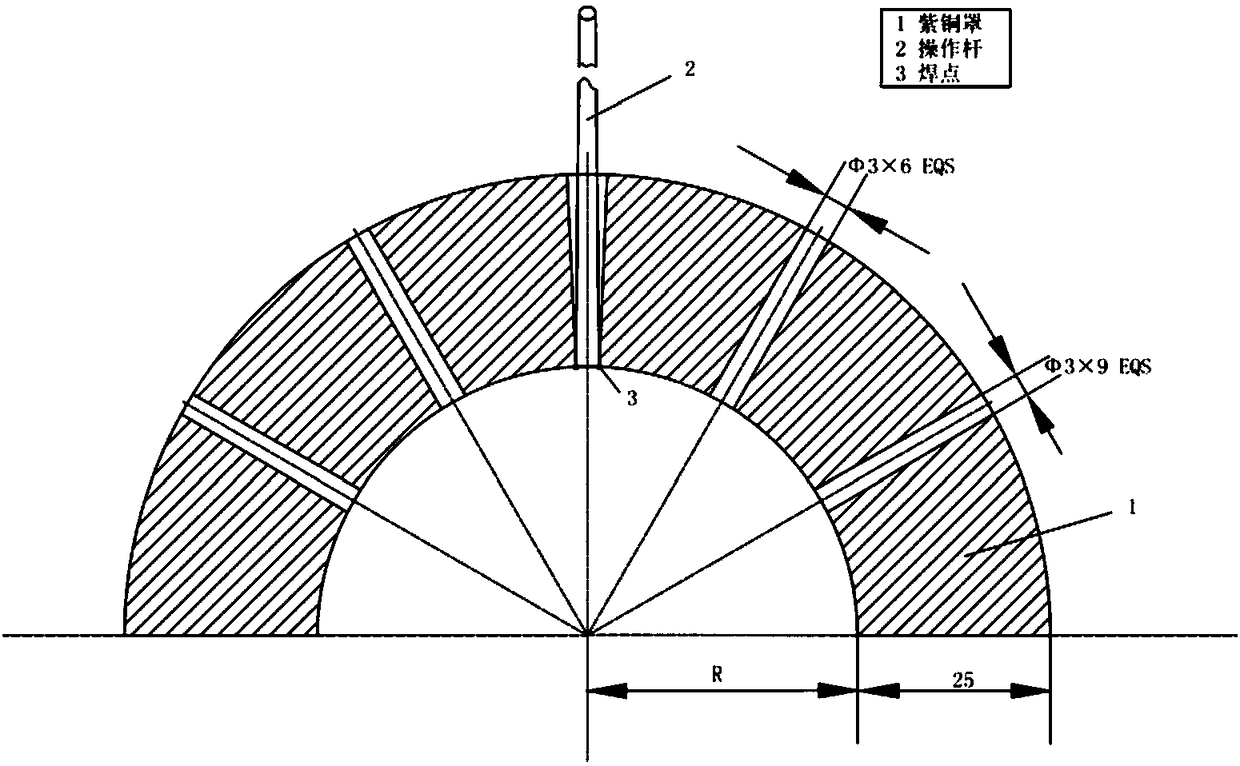

[0021] (2) 1.2 kilograms of titanium sponge is placed on the surface of the molten zinc obtained in step (1), and the titanium sponge is all pressed into the molten zinc by using an internal diameter of 41 millimeters and a self-dissolving red copper bell jar with a thickness of 25 millimeters. It is half of the depth of the bell jar entering the zinc solution;

[0022] (3) The zinc liquid of step (2) is heated up to 720 DEG C, and at the same time when the temperature is raised, the bell jar is constantly swimming back and forth at the corresponding depth in the zinc liquid, so that the sponge titanium and red copper are slowly dissolved into the zinc liquid at the same time, After the dissolution is sufficient, the resulting alloy liquid is poured into 40 kg of zinc-copper-titanium master alloy ingot.

...

Embodiment 2

[0033] (1) First place the 20# graphite crucible in the coke furnace, then put 28.7 kg of zinc ingot into the crucible and heat to 480°C for melting to obtain zinc liquid;

[0034] (2) 1.05 kilograms of titanium sponge is placed on the surface of the molten zinc obtained in step (1), and the titanium sponge is all pressed into the molten zinc by using an internal diameter of 37 millimeters and a self-dissolving red copper bell jar with a thickness of 25 millimeters. It is half of the depth of the bell jar entering the zinc solution;

[0035] (3) The zinc liquid of step (2) is heated up to 720 DEG C, and at the same time when the temperature is raised, the bell jar is constantly swimming back and forth at the corresponding depth in the zinc liquid, so that the sponge titanium and red copper are slowly dissolved into the zinc liquid at the same time, After the dissolution is sufficient, the resulting alloy solution is poured into a 35 kg zinc-copper-titanium master alloy ingot. ...

Embodiment 3

[0044] (1) First place the 16# graphite crucible in the coke furnace, then put 24.6 kg of zinc ingot into the crucible and heat it to 480°C for melting to obtain zinc liquid;

[0045](2) 0.9 kg of titanium sponge is placed on the surface of the molten zinc obtained in step (1), and the titanium sponge is all pressed into the molten zinc by using an internal diameter of 32 millimeters and a self-dissolving red copper bell jar with a thickness of 25 millimeters. It is half of the depth of the bell jar entering the zinc solution;

[0046] (3) The zinc liquid of step (2) is heated up to 720 DEG C, and at the same time when the temperature is raised, the bell jar is constantly swimming back and forth at the corresponding depth in the zinc liquid, so that the sponge titanium and red copper are slowly dissolved into the zinc liquid at the same time, After the dissolution is sufficient, the resulting alloy solution is poured into 30 kg of zinc-copper-titanium master alloy ingot.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com