Smoke plume particulate filter device of diesel generator set and method

A technology for diesel generator sets and particle trapping, which is applied to mufflers, exhaust devices, engine components, etc., can solve the problems of poor vibration resistance, thermal stress damage, uneven heating, etc., and achieves small size, simple maintenance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

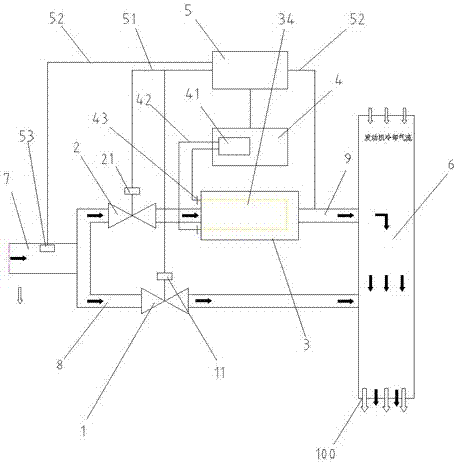

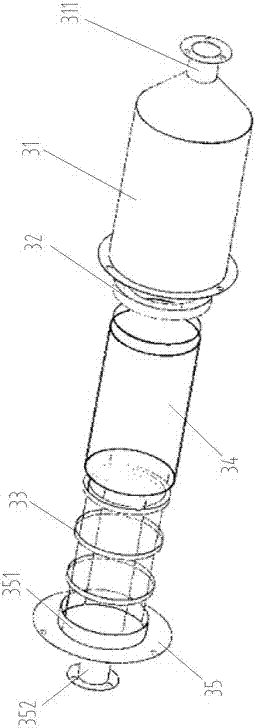

[0024] Such as figure 1 As shown, the present invention includes a first electric control shut-off valve 1, a second electric control shut-off valve 2, a metal fiber felt particle trap 3, an electric self-heating regeneration device 4, a controller 5 and a flue gas mixing cooling passage 6, and the diesel engine The smoke exhaust pipe 7 is connected to the connecting pipe 8 divided into two paths, and one connecting pipe 8 leads to the input end of the metal fiber felt particle trap 3 through the first electric control shut-off valve 1, and the output end of the metal fiber felt particle trap 3 The end communicates with the flue gas mixing cooling passage 6 through the pipe 9 . The other connecting pipe 8 communicates with the flue gas mixing cooling passage 6 through the second electric control shut-off valve 2 . The two ends of the heating power supply 41 of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com