Lead carbon battery, lead carbon battery negative pole plate and preparation method of lead carbon battery negative pole plate

A lead-carbon battery and negative plate technology, used in lead-acid battery electrodes, lead-acid batteries, etc., can solve the problems of increasing battery weight, unsuitable for cycle life and rate performance requirements, and a large number of grids, and achieves inhibition of sulfate. effect of improving cycle performance and rapid charge and discharge characteristics, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

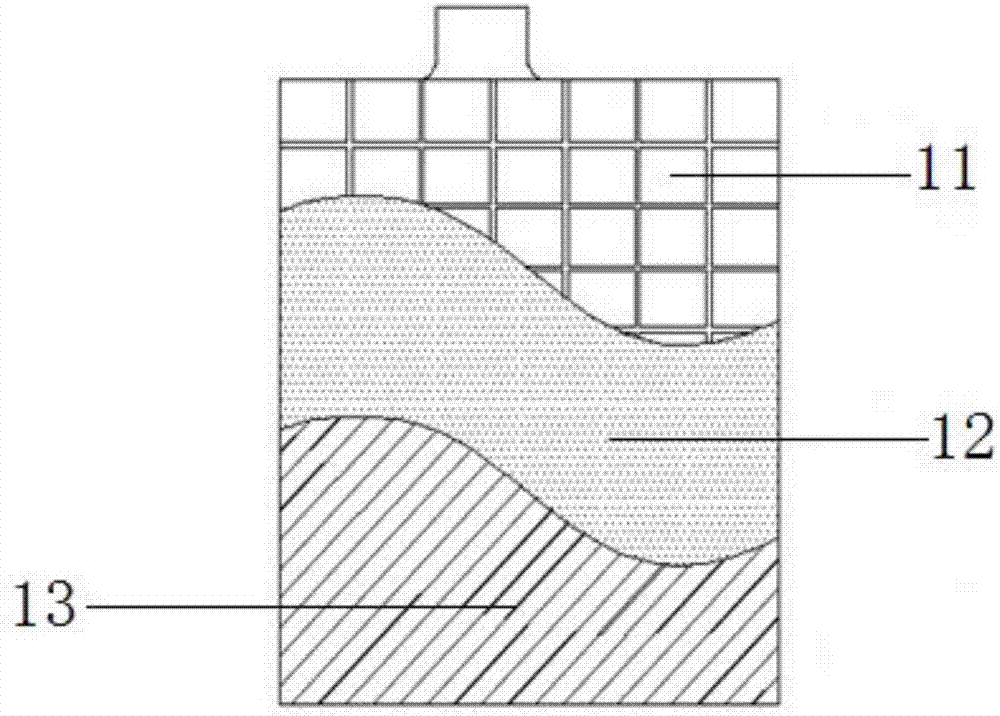

[0036] Embodiment 1 of the present invention provides a negative plate of a lead-carbon battery, figure 1 is a cross-sectional view of the negative plate, such as figure 1 As shown, the negative plate includes a grid 11, a lead paste 12 and a non-grid cloth patch 13; wherein,

[0037] The lead paste 12 is coated between the grid 11 and the non-mesh cloth patch 13, so that the grid 11 and the non-mesh cloth patch 13 are bonded to form a grid 11, lead paste 12 and A three-layer structure composed of non-grid cloth patch 13.

[0038]Specifically, according to the above scheme, the negative plate of the lead-carbon battery provided in the embodiment of the present invention adopts an original "sandwich" multi-layer structure, such as figure 1 As shown, it is divided into three layers from top to bottom. The first layer is grid 11, and the second layer is lead paste 12 containing lead, titanium, silicon and carbon materials with high capacity. It not only has certain electrical c...

Embodiment 2

[0062] Embodiment 2 of the present invention provides a lead-carbon battery, specifically, the lead-carbon battery includes: the negative electrode plate described in Embodiment 1.

Embodiment 3

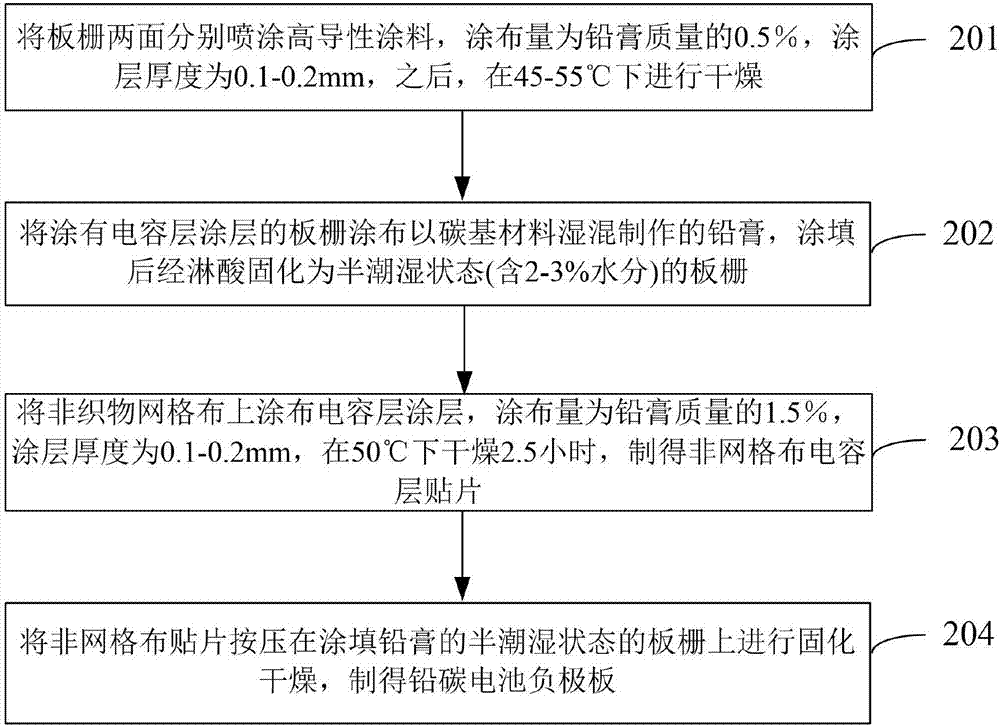

[0064] Embodiment 3 of the present invention provides a kind of preparation method of the negative plate of lead-carbon battery, refer to figure 2 , including the following steps:

[0065] Step 201: Spray the high-conductivity paddle on both sides of the grid, the coating amount is 0.5% of the mass of the lead paste, and the coating thickness is 0.1-0.2mm, and then dry at 45-55°C;

[0066] The components and the ratio of each component in the high-conductivity slurry can be: 99 parts of electrodeposited lead-titanium silicon compound, 1 part of binder and 500 parts of ionized water; wherein, the electrodeposited lead The mass percent of the activated carbon of the titanium silicon compound is 5-10%, the mass percent of the carbon black of the electrodeposited lead titanium silicon compound is 30-40%, and the mass percent of the graphite of the electrodeposited lead titanium silicon compound is 30- 40%, the mass percentage of the VGCF of the electrodeposited lead-titanium-sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com