Pt-supported mesoporous polypyrrole nanoring catalyst and preparation method therefor

A technology of mesoporous polypyrrole nanometer and pyrrole nanometer, applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problems of low activity and easy poisoning of platinum-carbon catalysts, achieve good anti-toxic performance and enhanced catalytic activity , the effect of enhancing the anti-toxic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of mesoporous polypyrrole nano ring supported Pt catalyst, the steps are as follows:

[0036] 1) Mix 9.0g of deionized water, 30.8mL of ammonia water and 160mL of absolute ethanol under magnetic stirring and set aside.

[0037] 2) Prepare 200 mL of an ethanol solution containing 17.5 g of tetraethyl orthosilicate (TEOS) and quickly add it to the solution prepared in step 1). After 12 hours of magnetic stirring at 25°C, a white emulsion was obtained.

[0038] 3) The white emulsion obtained in step 2) is centrifuged to obtain silica microspheres (ball diameter is 350nm), and the silica spheres are ultrasonically dispersed in deionized water to prepare silica sphere sol, silica The mass of the microspheres is 10% of the mass of the sol.

[0039] 4) Add 0.13g of pyrrole and 0.16g of sodium acetate in 5mL of water, then add 5mL of the silica microsphere sol prepared in step 3), and finally add 0.2mol L -1FeCl 3 10 mL of aqueous solution was used as...

Embodiment 2

[0045] The preparation method of the mesoporous polypyrrole nanoring-supported Pt catalyst has the same steps as in Example 1, except that the amount of TEOS in step 2) is 8.5 g, and the diameter of the prepared silica microspheres is 280 nm.

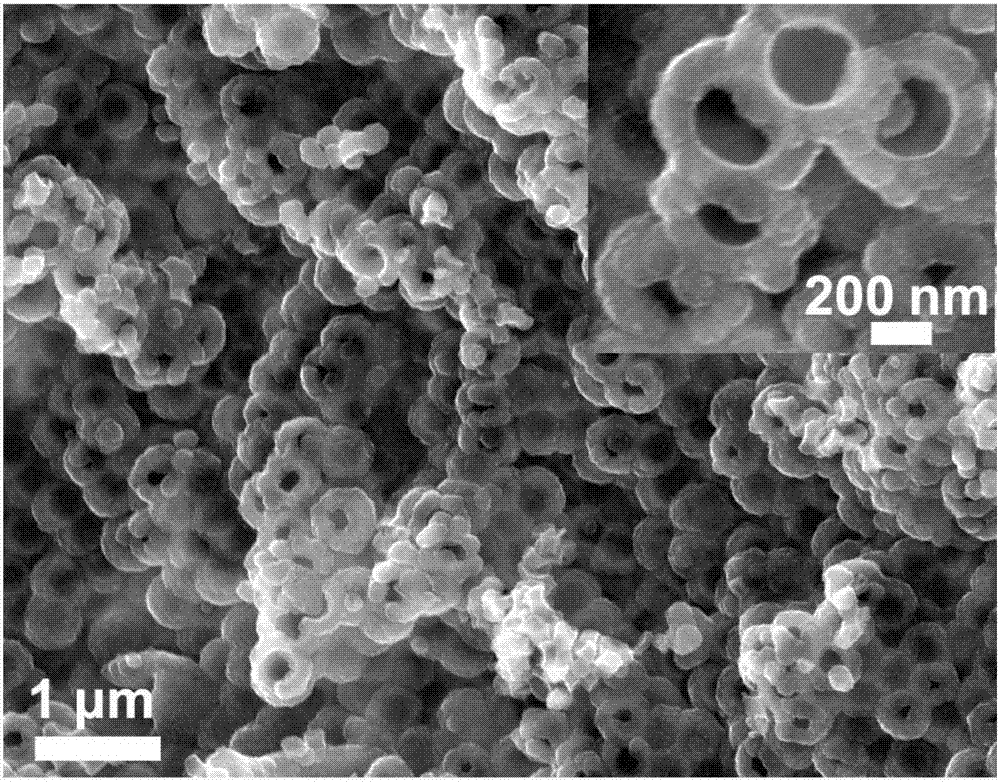

[0046] figure 2 Shown is the SEM picture of the mesoporous polypyrrole nanorings prepared in this example. It can be seen from the figure that the sample has a good ring structure and is uniformly dispersed. From the inset, it can be measured that the diameter of the inner ring of the sample is 280 nm, and the wall thickness is 60 nm. The inner diameter of the nanoring is consistent with the spherical diameter of the silica microspheres in the silica template.

Embodiment 3

[0048] The preparation method of the mesoporous polypyrrole nanoring-supported Pt catalyst has the same steps as in Example 1, except that the amount of TEOS in step 2) is 21.5 g, and the diameter of the prepared silica microspheres is 450 nm.

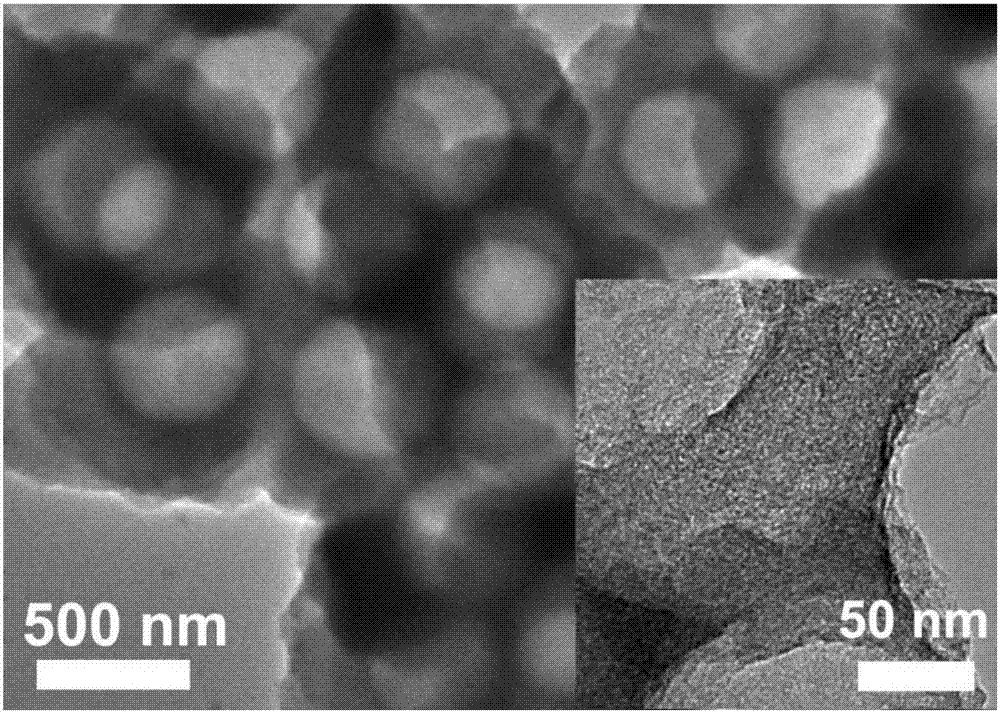

[0049] image 3 Shown is the TEM picture of the mesoporous polypyrrole nanorings prepared in this example. It can be seen from the figure that the sample has a good ring structure and is uniformly dispersed. From the enlarged view of a single polypyrrole nanoring in the inset, it can be seen that there are mesoporous structures in the pore walls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com