Low reflection coating, glass plate, glass substrate, and photoelectric conversion device

A low-reflection, coating technology, used in coating, photovoltaic power generation, optics, etc., to achieve high transmittance gain and excellent removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

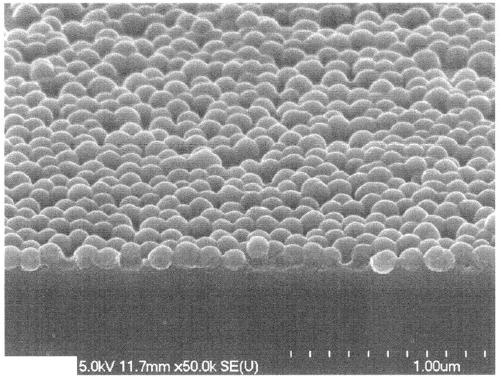

Image

Examples

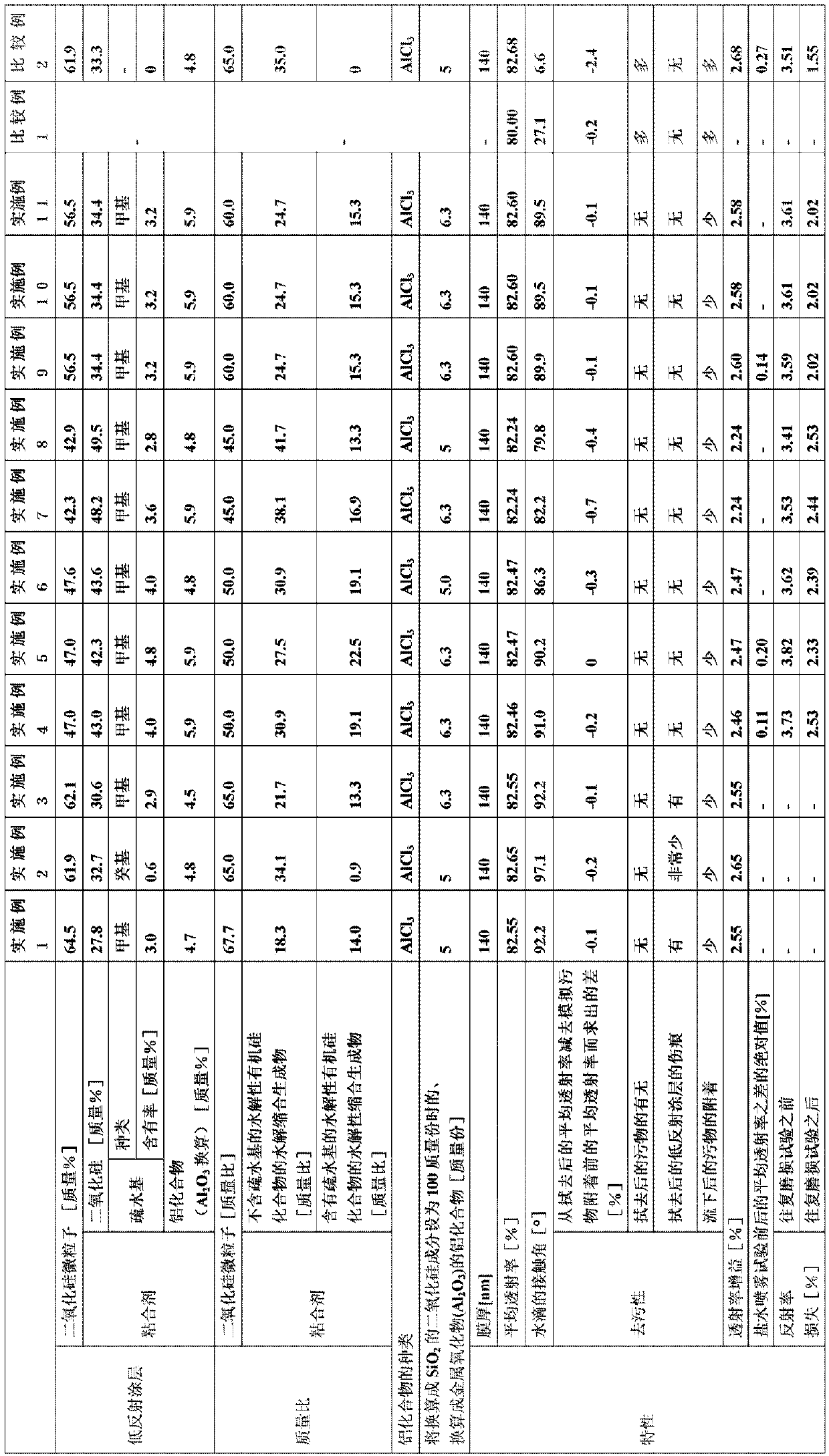

Embodiment 1

[0082] (Preparation of coating solution)

[0083] Silica microparticle dispersion (Quartron PL-7, approximately spherical primary particles with an average particle diameter of 125 nm, solid content concentration 23% by weight, manufactured by Fuso Chemical Industry Co., Ltd.) 56.2 parts by mass, 1-methoxy-2- 23.3 parts by mass of propanol (solvent), 1 part by mass of 1N hydrochloric acid (hydrolysis catalyst) were stirred and mixed, and 12.1 parts by mass of tetraethoxysilane (tetraethoxysilane, manufactured by Tama Chemical Industry Co., Ltd.) and methyl 7.1 parts by mass of methyltriethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd.), stirred for 8 hours while continuing to keep warm at 40° C., hydrolyzed tetraethoxysilane and methyltriethoxysilane, and obtained stock solution A. In stock solution A, the ratio of the mass of silica fine particles to the mass of the hydrolysis condensation product of the hydrolyzable silicon compound contained in the binder is 67.7:3...

Embodiment 2

[0090] (Preparation of coating solution)

[0091] 28.3 parts by mass of the silica microparticle dispersion used in Example 1, 58.6 parts by mass of 1-methoxy-2-propanol (solvent), and 1 part by mass of 1N hydrochloric acid (hydrolysis catalyst) were stirred and mixed, and further stirred while Added 12.1 parts by weight of tetraethoxysilane (tetraethoxysilane, manufactured by Tama Chemical Industry Co., Ltd.), and stirred for 8 hours while continuing to keep warm at 40°C to hydrolyze the tetraethoxysilane to obtain stock solution B. In stock solution B, convert silica particles into SiO 2 The mass of the silicon oxide contained in the adhesive is converted into SiO 2 The mass ratio is 65:35, converted to SiO 2 The solid content concentration was 10% by mass. Stock solution B does not contain hydrophobic groups.

[0092] 70.0 g of the above stock solution B, 2.0 g of propylene glycol (solvent), 26.3 g of 1-methoxy-2-propanol (solvent), 1.7 g of the aluminum chloride aqueou...

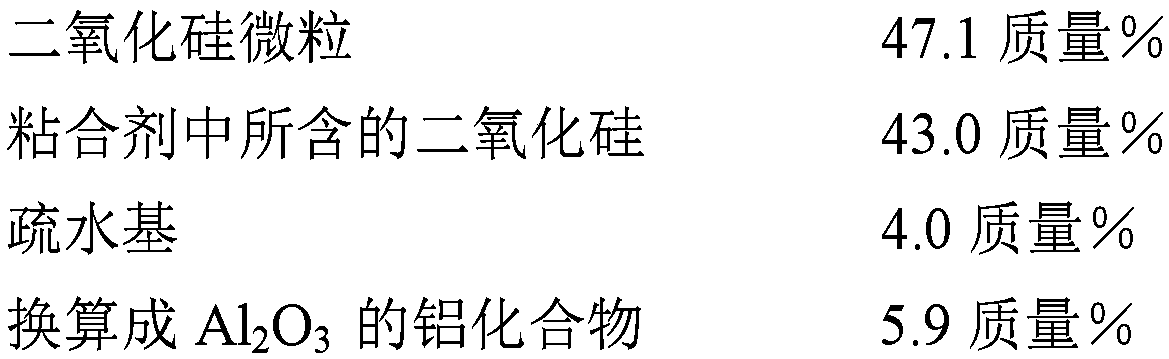

Embodiment 4

[0099] Silica microparticle dispersion (Quartron PL-7, approximately spherical primary particles with an average particle diameter of 125 nm, solid content concentration 23% by weight, manufactured by Fuso Chemical Industry Co., Ltd.) 21.7 parts by mass, 1-methoxy-2- 64.5 parts by mass of propanol (solvent) and 1 part by mass of 1N hydrochloric acid (hydrolysis catalyst) were stirred and mixed, and a partial hydrolysis condensate of tetraethoxysilane (manufactured by Colcoat Co., Ltd., trade name: ethyl silicate 40 , abbreviation: ES-40, average pentamer oligomer) 7.7 parts by mass, methyltriethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd.) 5.1 parts by mass, and stirred for 8 hours while continuing to keep warm at 40°C, Hydrolyze ES-40 and methyltriethoxysilane to obtain stock solution C.

[0100] Stock solution C70.0g, propylene glycol (solvent) 2.0g, 1-methoxy-2-propanol (solvent) 25.9g, aluminum chloride aqueous solution (as AlCl 3 The concentration was 47.6 wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com