Device for improving quality of plant materials through hot pressing

A plant material and quality technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve problems such as failure to function, insufficient utilization of plant crop by-products, environmental pollution, etc., to solve the problem of atmospheric and environmental pollution , the effect of increased plasticity and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

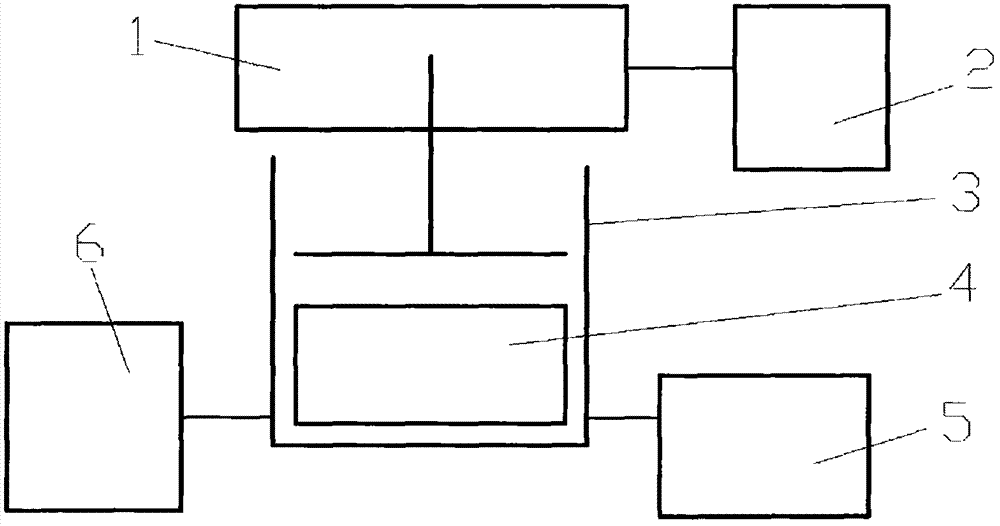

[0043] exist figure 1 Among them, the plant material (4) enters the mold system (3) from the feeding and unloading system (5), and is heated to a suitable temperature by the heating and cooling and auxiliary system (6). Under the control of the control system (2), the pressure system The piston system of (1) pressurizes the plant material (4) in the mold system (3), and after pressurizing to the set pressure, the plant material (4) is cooled to normal temperature by the heating cooling and auxiliary system (6). Finally, the finished product can be taken out by the feeding and unloading system (5). The auxiliary matters required for normal operation are all realized and completed by the auxiliary system of the heating cooling and auxiliary system (6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com