Anaerobic membrane bioreactor for effectively treating kitchen waste water and treatment method using the same

A technology of anaerobic membrane biology and kitchen wastewater, applied in the direction of biological treatment adjustment methods, chemical instruments and methods, waste fuels, etc., to achieve the effects of reducing accumulation, reducing cumulative concentration, and slowing down the tendency of membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

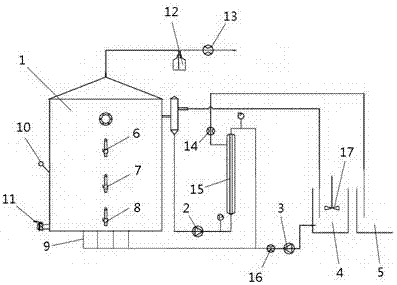

[0019] An anaerobic membrane bioreactor for effectively treating kitchen wastewater. The anaerobic membrane bioreactor includes an anaerobic tank 1, a circulation pump 2, an inlet pump 3, an inlet pool 4, and an outlet pool 5 from left to right. Tank 1 has a volume of 1m 3 , the circulation pump 2 and the water inlet pump 3 are respectively connected to the anaerobic tank 1, and the control cross-flow rate of the circulation pump 2 is 2.2 m s -1 , the water inlet pool 4 is connected with the water inlet pump 3, the front of the tank body of the anaerobic tank 1 is provided with sampling port I 6, sampling port II 7 and sampling port III 8, the bottom of the anaerobic tank 1 is provided with a water distributor 9, and the anaerobic tank 1 The left side is provided with a temperature probe 10 and an emptying port 11 respectively. The temperature probe 10 is located above the emptying port 11. A water seal tank 12 and a gas flow meter 13 are connected above the anaerobic tank 1. ...

Embodiment 2

[0023] An anaerobic membrane bioreactor for effectively treating kitchen wastewater. The anaerobic membrane bioreactor includes an anaerobic tank 1, a circulation pump 2, an inlet pump 3, an inlet pool 4, and an outlet pool 5 from left to right. Tank 1 has a volume of 1m 3 , the circulation pump 2 and the water inlet pump 3 are respectively connected to the anaerobic tank 1, and the control cross-flow rate of the circulation pump 2 is 2.2 m s -1 , the water inlet pool 4 is connected with the water inlet pump 3, the front of the tank body of the anaerobic tank 1 is provided with sampling port I 6, sampling port II 7 and sampling port III 8, the bottom of the anaerobic tank 1 is provided with a water distributor 9, and the anaerobic tank 1 The left side is provided with a temperature probe 10 and an emptying port 11 respectively. The temperature probe 10 is located above the emptying port 11. A water seal tank 12 and a gas flow meter 13 are connected above the anaerobic tank 1. ...

Embodiment 3

[0027] An anaerobic membrane bioreactor for effectively treating kitchen wastewater. The anaerobic membrane bioreactor includes an anaerobic tank 1, a circulation pump 2, an inlet pump 3, an inlet pool 4, and an outlet pool 5 from left to right. Tank 1 has a volume of 1m 3 , the circulation pump 2 and the water inlet pump 3 are respectively connected to the anaerobic tank 1, and the control cross-flow rate of the circulation pump 2 is 2.2 m s -1 , the water inlet pool 4 is connected with the water inlet pump 3, the front of the tank body of the anaerobic tank 1 is provided with sampling port I 6, sampling port II 7 and sampling port III 8, the bottom of the anaerobic tank 1 is provided with a water distributor 9, and the anaerobic tank 1 The left side is provided with a temperature probe 10 and an emptying port 11 respectively. The temperature probe 10 is located above the emptying port 11. A water seal tank 12 and a gas flow meter 13 are connected above the anaerobic tank 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com