Thermosetting plastic and its preparation method and power lithium battery pack assembly casing prepared from thermosetting plastic

A manufacturing method and thermosetting technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as unfavorable lightweight development of vehicles, heavy metal box body, damaged battery cells, etc., and achieve instant control of danger and weight. The effect of lightening and reducing accident losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

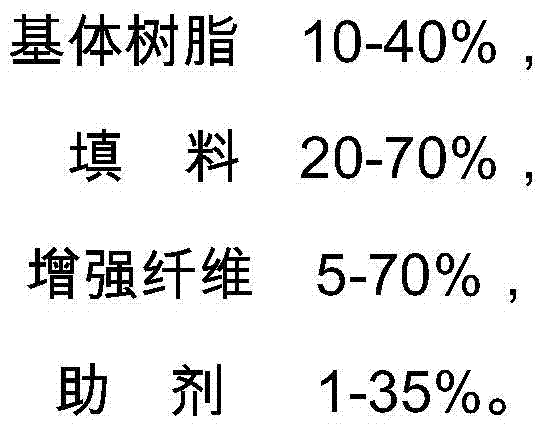

[0035] Embodiment 1, the weight ratio formula of thermosetting plastic is as follows:

[0036]

[0037]

Embodiment 2

[0038] Embodiment 2, the weight ratio formula of thermosetting plastics is as follows:

[0039]

[0040] A method for manufacturing a thermosetting plastic, comprising the steps of:

[0041] (1) Weigh the matrix resin, fillers, reinforcing fibers and additives according to the proportion of the formula, and put them into a high-speed disperser to disperse evenly;

[0042] (2) Put the above-mentioned matrix resin, filler, reinforcing fiber and auxiliary agent into a mixer and mix at high speed, then knead with a kneader, and then perform impregnation treatment to obtain a thermosetting plastic mixture;

[0043] (3) Under the specified temperature and pressure conditions, the above-mentioned thermosetting plastic mixture is solidified and formed in the mold of the product, and the shape of the product is fixed while the mixture is solidified.

[0044] The auxiliary agent in the step (1) includes a catalyst, a release agent and a flame retardant, first mix the composition of ...

Embodiment 1

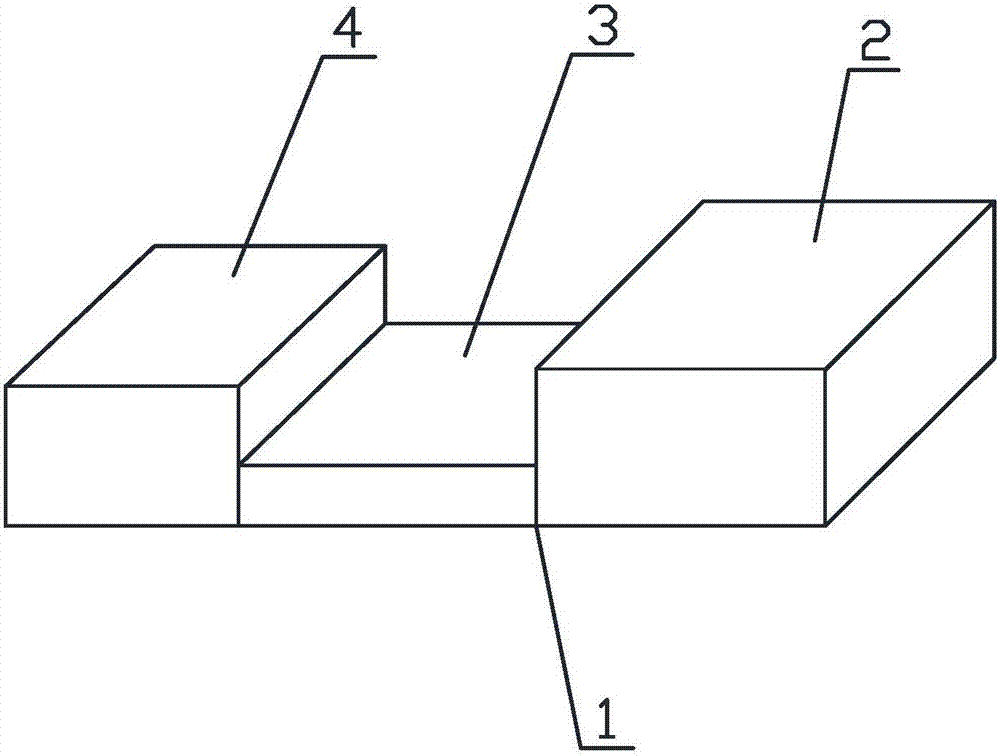

[0048] Embodiment one, such as figure 1 As shown, the assembly box body is composed of the first unit box 2, the second unit box 3 and the third unit box 4 connected to each other in the horizontal direction, and the three unit boxes are of different sizes. Each single box forms an integral structure by injection molding, and the wall thickness of the single box is 2-5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com