Flowing anti-caking auxiliary agent for powder paint and preparation method thereof

A powder coating and anti-caking technology, which is applied in the direction of polyester coating, epoxy resin coating, coating, etc., can solve the problems of fog and shadow on the surface of the coating film, poor anti-coagulation and agglomeration, and high cost. It achieves the effect of improving charging and corner coverage, good anti-coagulation and particle performance, and reducing investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

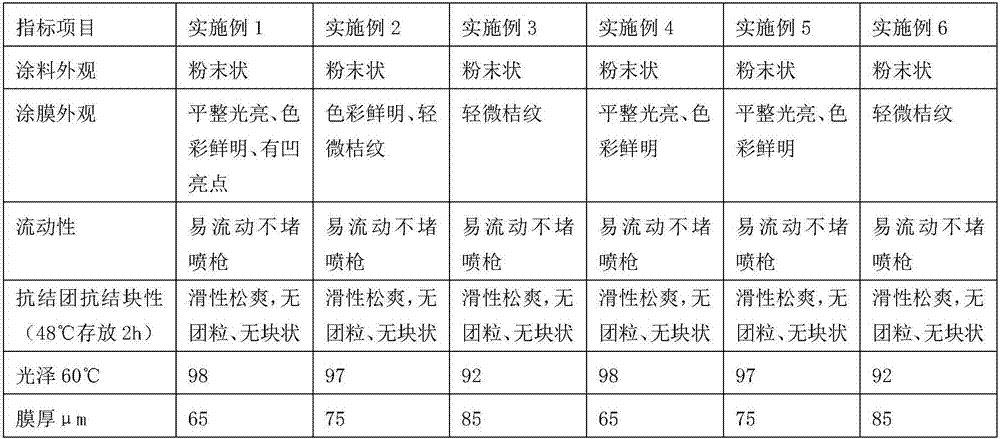

Examples

Embodiment 1

[0026] A preparation method for a flow anti-caking additive for powder coatings, comprising the following steps:

[0027] 1) Put 20kg of precipitated silica, 15kg of fumed silica, 10kg of polyamide wax, and 30kg of vinyl bisstearamide into the GHJ-400L mixer with high-speed crushing function (Shandong Shengshida Machinery Co., Ltd. Technology Co., Ltd. equipment, the power of the hybrid motor is 18.5KW, the speed is 480r / min, the power of the high-speed crushing motor is 7.5KW, the speed is 1500r / min).

[0028] 2) Start the mixing motor of the mixer with high-speed crushing function first, mix for 2 minutes, then start the high-speed crushing motor, grind and mix at high speed for 8 minutes, carry out depolymerization and refinement, so that the raw material particles are refined, and each raw material is fully and evenly dispersed to obtain Flowing anti-blocking additive for powder coatings.

[0029] Among them, the average particle size of precipitated silica is 4.5-5.5 mic...

Embodiment 2

[0031] Similar to Example 1, the difference is that the raw materials are composed of: 30 kg of precipitated silica, 10 kg of fumed silica, 20 kg of polyamide wax, and 20 kg of vinyl bisstearamide.

Embodiment 3

[0033] Similar to Example 1, the difference is that the raw material composition is: 40 kg of precipitated silica, 5 kg of fumed silica, 30 kg of polyamide wax, and 10 kg of vinyl bisstearamide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com