High temperature-resistant water-based paint for engines and preparation method thereof

A high-temperature-resistant, water-based paint technology, applied in coatings, fire-retardant coatings, etc., can solve problems such as environmental pollution, and achieve the effects of improving the working environment, prolonging service life, and reducing toxic and harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

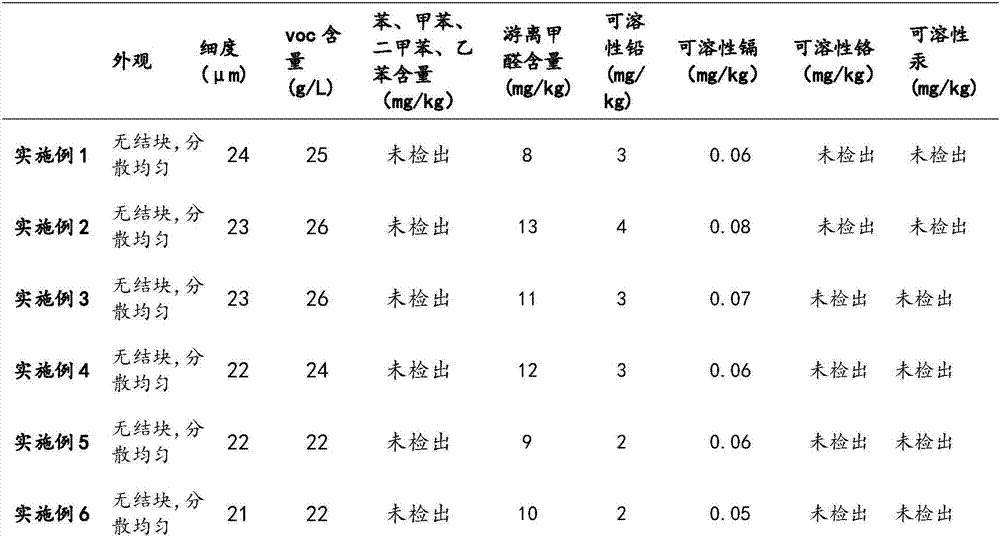

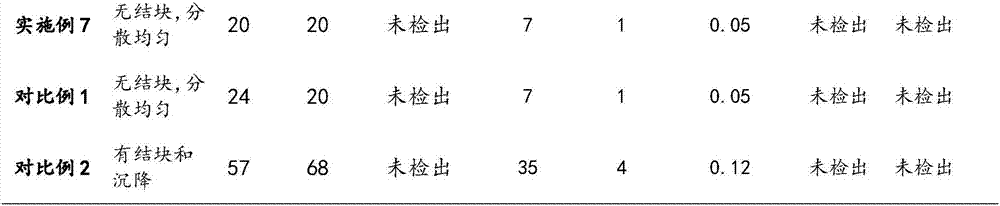

[0039] According to another aspect of the present invention, the present invention provides a method for preparing the above-mentioned high-temperature-resistant water-based paint for engines, comprising the steps of: weighing water-based acrylic resin, water-based amino resin, water-based silver paste, pigments, additives, deionized Water and an optional co-solvent are uniformly mixed and ground to obtain a high-temperature-resistant water-based paint for an engine.

[0040] In a preferred embodiment of the present invention, the particle size of the prepared high-temperature-resistant water-based paint for engines is less than 25 μm by grinding.

[0041] The preparation method of the high-temperature-resistant water-based paint for engines provided by the invention uses deionized water as a solvent, has a simple process, is convenient to prepare, can effectively improve the working environment of painting workers, reduce use costs, and promote the coordinated development of t...

Embodiment 1

[0044] This embodiment provides a high temperature resistant water-based paint for engines, comprising the following components in parts by mass: 25 parts of water-based acrylic resin, 5 parts of water-based amino resin, 2 parts of water-based silver paste, 0.5 part of carbon black, medium yellow 1 part, 1 part of bright red, 0.2 parts of defoamer, 0.2 parts of leveling agent, 0.2 parts of wetting agent, 1 part of dispersant, 0.5 parts of dimethylethanolamine, 3 parts of ethylene glycol butyl ether, 25 parts of deionized water Wherein, the water-based acrylic resin is selected from the XP2427 resin of Bayer Corporation, the water-based amino resin is selected from the HW180PC of BASF Corporation, and the defoamer is selected from Tego 805 of Digao Company, and the leveling agent is selected from Byk 381 of Bi Ke Company, wetting agent It is selected from Tego 260 of Tego Company, and the dispersant is selected from Gen0451 of Borchers Company.

Embodiment 2

[0046] This embodiment provides a high temperature resistant water-based paint for an engine, comprising the following components in parts by mass: 45 parts of water-based acrylic resin, 25 parts of water-based amino resin, 10 parts of water-based silver paste, 1 part of carbon black, medium yellow 2 parts, 2 parts of bright red, 0.4 parts of defoamer, 0.4 parts of leveling agent, 0.4 parts of wetting agent, 2 parts of dispersant, 1 part of dimethylethanolamine, 9 parts of ethylene glycol butyl ether, 15 parts of deionized water Wherein, water-based acrylic resin is selected from New Pace Company SC6638 resin, water-based amino resin is selected from Bayer Company XP2655, defoamer is selected from Byk 011 of Bi Ke Company, leveling agent is selected from Tego 270 of Tego Company, and wetting agent is selected from Dispersant selected from Byk 181 from 3M company FC 4430.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

| Water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap