Square wave injected method for estimating rotor position, after time delay compensation, of permanent magnet synchronous motor (PMSM)

A permanent magnet synchronous motor, rotor position estimation technology, applied in the control of generators, motor generator control, control of electromechanical transmission devices, etc., can solve the problem of aggravating the influence of position estimation accuracy, position estimation error, sampling point distortion, etc. Achieve the effect of reducing the response current distortion rate, improving the position estimation accuracy, and increasing the bandwidth of the control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

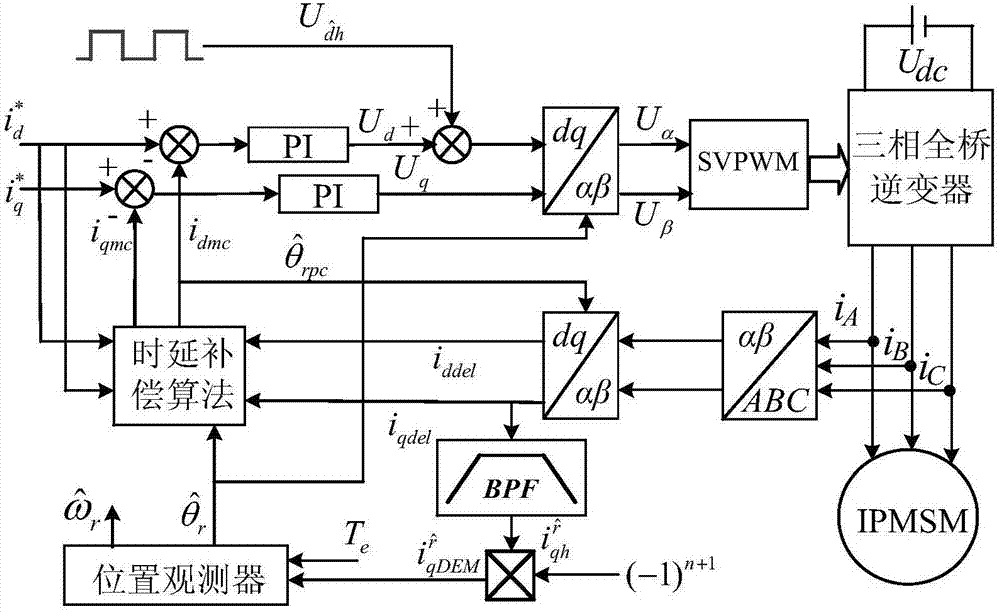

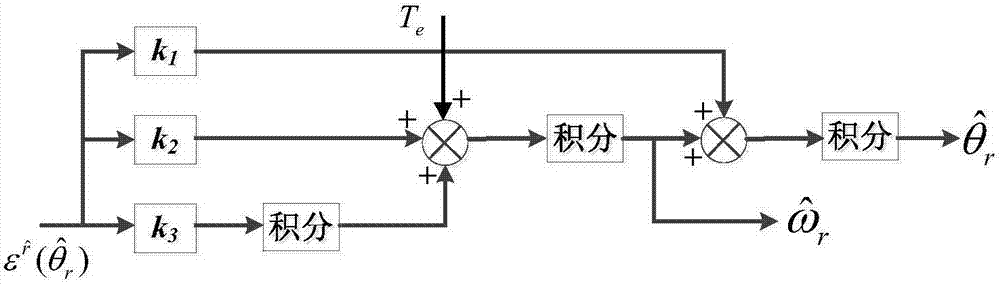

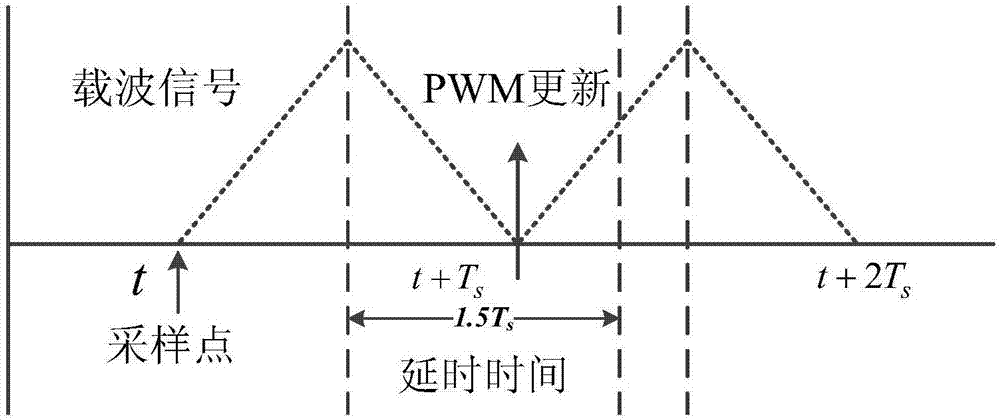

[0058] The present invention is a position sensorless control strategy that realizes the position estimation of permanent magnet synchronous motor through square wave voltage injection. Considering the PWM signal hysteresis caused by low switching frequency and the position estimation error caused by the reduction of injected harmonic frequency, through the analysis of low The hysteresis mechanism of PWM signal at switching frequency and the influence of delay on system stability, a time delay compensation algorithm is proposed, and a position sensorless closed-loop control model suitable for low switching frequency is established, aiming at realizing the magnetization component of stator current Effective decoupling of torque and torque components, thereby improving the response current distortion rate at low switching frequencies and improving the accuracy of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com