Alcohol-soluble phenolic resin dip-coating glue liquid, oil-water separation fuel oil filter paper and preparation method of oil-water separation fuel oil filter paper

A phenolic resin and oil-water separation technology, applied in the field of filter paper, can solve the problem of inability to separate water and achieve long service life, large dust holding capacity, and high-efficiency filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Alcohol-soluble phenolic resin dipping glue with oil-water separation, its raw material components and weight percentages are as follows:

[0051] Oil-water separation phenolic resin LD-1 51.2%, methanol 48.8%.

[0052] A preparation method for oil-water separation fuel oil filter paper, comprising the following steps:

[0053] (1) Base paper preparation: Weigh mixed fibers composed of cellulose fibers and synthetic fibers and soak for 45 minutes to disintegrate. In the mixed fibers, cellulose fibers account for 80% and synthetic fibers account for 20% by weight. After the disintegration is completed, it is disintegrated by the disintegrator and then introduced into the disintegrating pulp tank. After being diluted with white water in the disintegrating pulp tank, it is refined by a conical refiner and then introduced into the forebear tank. The high-level box adjusts the wet strength agent diluted to 2% concentration to the flow rate of 5L / h with a metering pump and a...

Embodiment 2

[0057] Alcohol-soluble phenolic resin dipping glue with oil-water separation, its raw material components and weight percentages are as follows:

[0058] Oil-water separation phenolic resin LD-1 55%, methanol 45%.

[0059]A kind of preparation method of oil-water separation fuel oil filter paper, with embodiment 1, difference is:

[0060] In the mixed fibers in step (1), by weight, cellulose fibers account for 95%, and synthetic fibers account for 5%.

experiment example

[0061] Experimental example: Filtration accuracy experiment

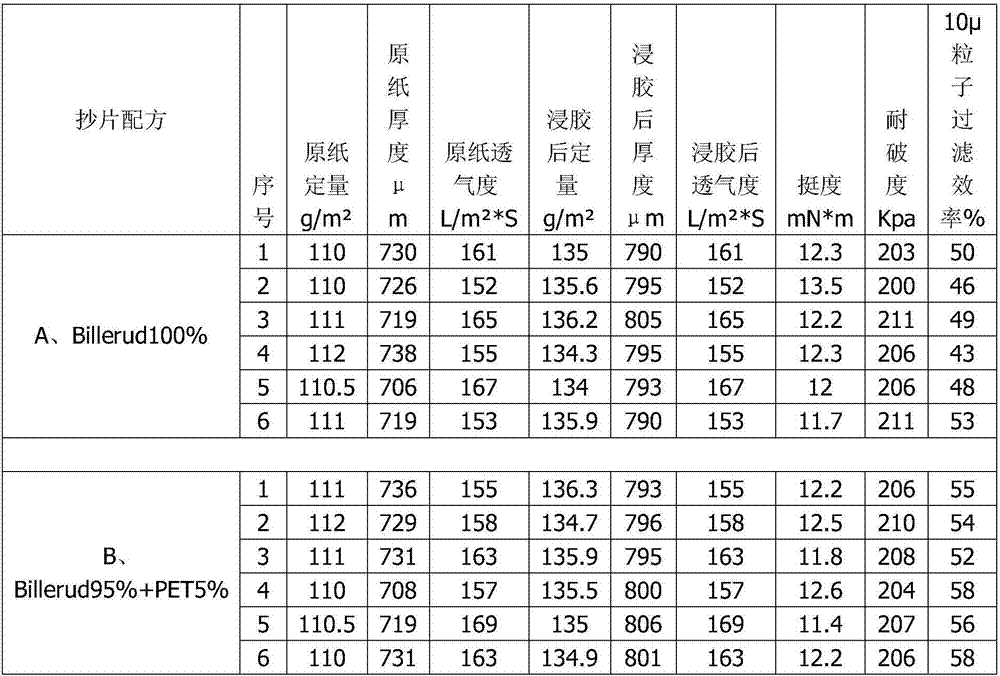

[0062] Use FTH-1 sheet machine to make paper sample A and paper sample B respectively, paper sample A adopts pure wood pulp fiber, paper sample B adopts the mixed fiber of the embodiment 2 of the present invention, and in the mixed fiber by weight ratio, cellulose fiber accounts for 95% , synthetic fibers accounted for 5%. Then use the conventional heat-curable phenolic aldehyde and the dip coating glue of the present invention to coat respectively, and use the DT-100 multi-pass test bench to test the filtration accuracy after making paper samples with the same quantity. The base paper weight is 110g / m 2 , after coating with phenolic resin, the quantitative value is 135g / m 2 , respectively tested the air permeability, stiffness, burst resistance and filtration efficiency of each paper sample after dipping, and the results are shown in Table 1 below.

[0063] Table 1 Air permeability, stiffness, burst resistance a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com