Preparation method and application of skin dressing containing carrageenan/agarose

A technology of agarose and carrageenan, which is applied in medical science, absorbent pads, prostheses, etc., can solve problems such as property differences, and achieve the effects of low manufacturing cost, strong stability, and infection prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

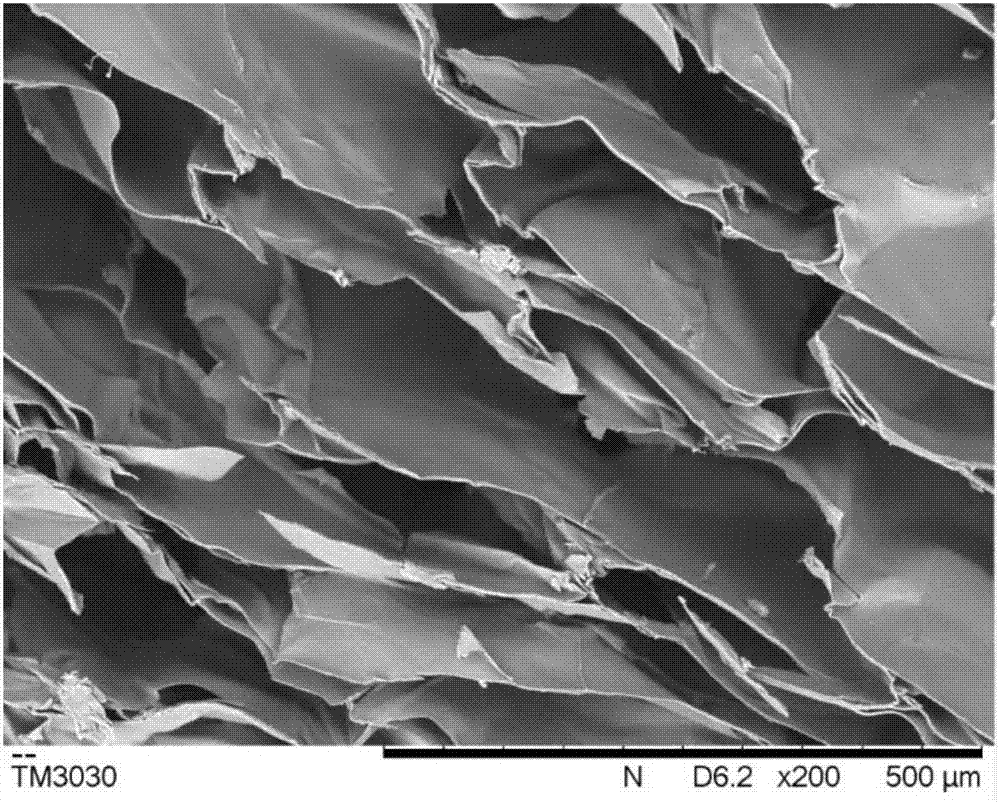

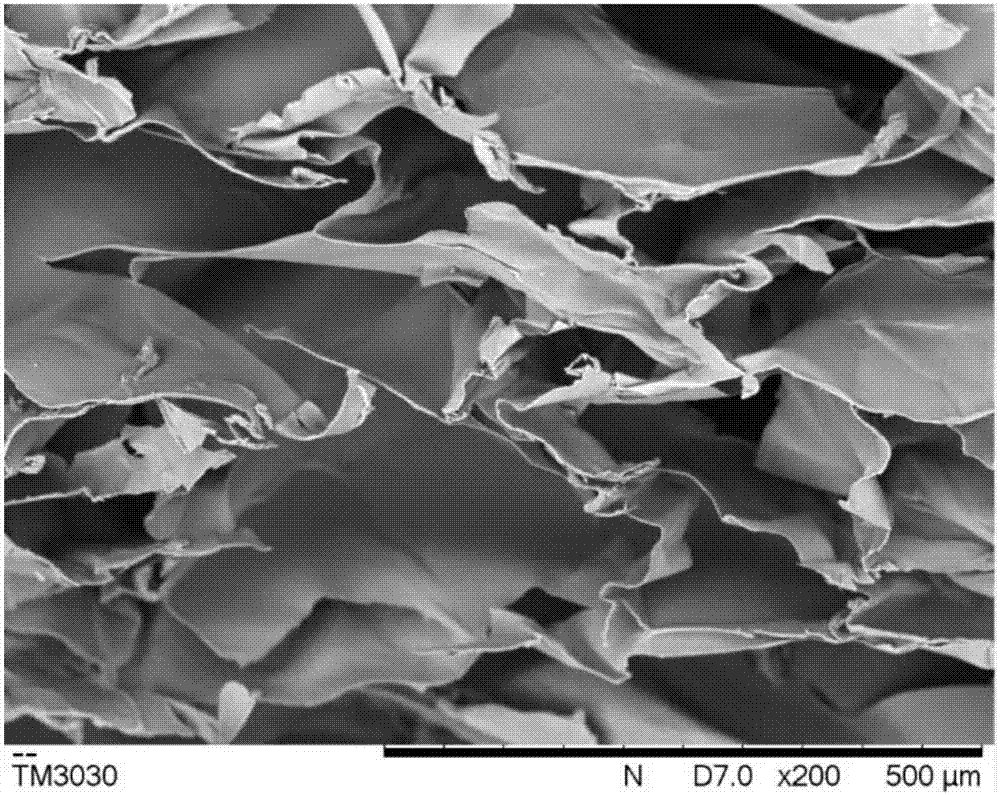

Image

Examples

Embodiment 1

[0047] A skin dressing composite film containing λ-type carrageenan / agarose is a composite film composed of λ-type carrageenan and agarose in a mass ratio of 50:50.

[0048] The above-mentioned preparation method of the skin dressing composite film containing λ type carrageenan / agarose comprises the following steps:

[0049] (1) Prepare a commercial-grade λ-carrageenan solution with a mass fraction of 10%, heat it in a water bath at 90°C until it is completely dissolved, and filter it while it is hot. Add the same volume of 0.8mol / L KCl solution. Put it into a 50mL centrifuge tube and centrifuge at high speed (8000rpm, 10min), and take the supernatant into a clean beaker. Add twice the volume of absolute ethanol and decant. The precipitate was dialyzed in a dialysis bag with a molecular weight cut off of 3000 for three days, and concentrated by rotary evaporation. Place in a -20°C refrigerator and freeze overnight, then freeze-dry.

[0050] (2) Dissolving the agarose with ...

Embodiment 2

[0058] A skin dressing composite scaffold containing κ-type carrageenan / agarose is a composite scaffold material composed of κ-type carrageenan and agarose in a mass ratio of 40:60, and the tensile modulus is 0.292MPa.

[0059] The preparation method of the above-mentioned skin dressing composite support containing κ-type carrageenan / agarose comprises the following steps:

[0060] (1) Prepare a commercial grade κ-carrageenan solution with a mass fraction of 10%, place it in a water bath at 90°C to dissolve it by heating, and filter while it is hot. Add the same volume of 0.8mol / L KCl solution. Let stand at room temperature, decant and discard the supernatant. Put it into a dialysis bag with a molecular weight cut off of 3000 and dialyze for three days, then concentrate by rotary evaporation. Place in a -20°C freezer overnight and freeze dry.

[0061] (2) Dissolving the agarose with pure water at 90° C. to obtain an agarose solution with a mass fraction of 1%.

[0062] (3) ...

Embodiment 3

[0067] A skin dressing composite support containing iota-type carrageenan / agarose is a composite support material composed of iota-type carrageenan and agarose according to a mass ratio of 50:50, and the tensile modulus is 0.321MPa.

[0068] The preparation method of the above-mentioned skin dressing composite support containing iota carrageenan / agarose may further comprise the steps:

[0069] (1) Prepare a commercial grade iota-carrageenan solution with a mass fraction of 10%, place it in a water bath at 90° C. and heat until completely dissolved, and filter while it is hot. Add the same volume of 0.8mol / L KCl solution. Place in a 50mL centrifuge tube and centrifuge at high speed (8000rpm, 20min), discard the supernatant. The precipitate was dialyzed in a dialysis bag with a molecular weight cut off of 3000 for three days, and concentrated by rotary evaporation. Place in a -20°C freezer overnight and freeze dry.

[0070] (2) Dissolving the agarose with pure water at 90° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com