Wet treatment process and wet treatment system for PB (particle board) dry tail gas

A technology for dry tail gas and wet treatment, applied in gas treatment, climate sustainability, greenhouse gas capture, etc., to reduce investment, reduce maintenance workload, and improve the effect of foam dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

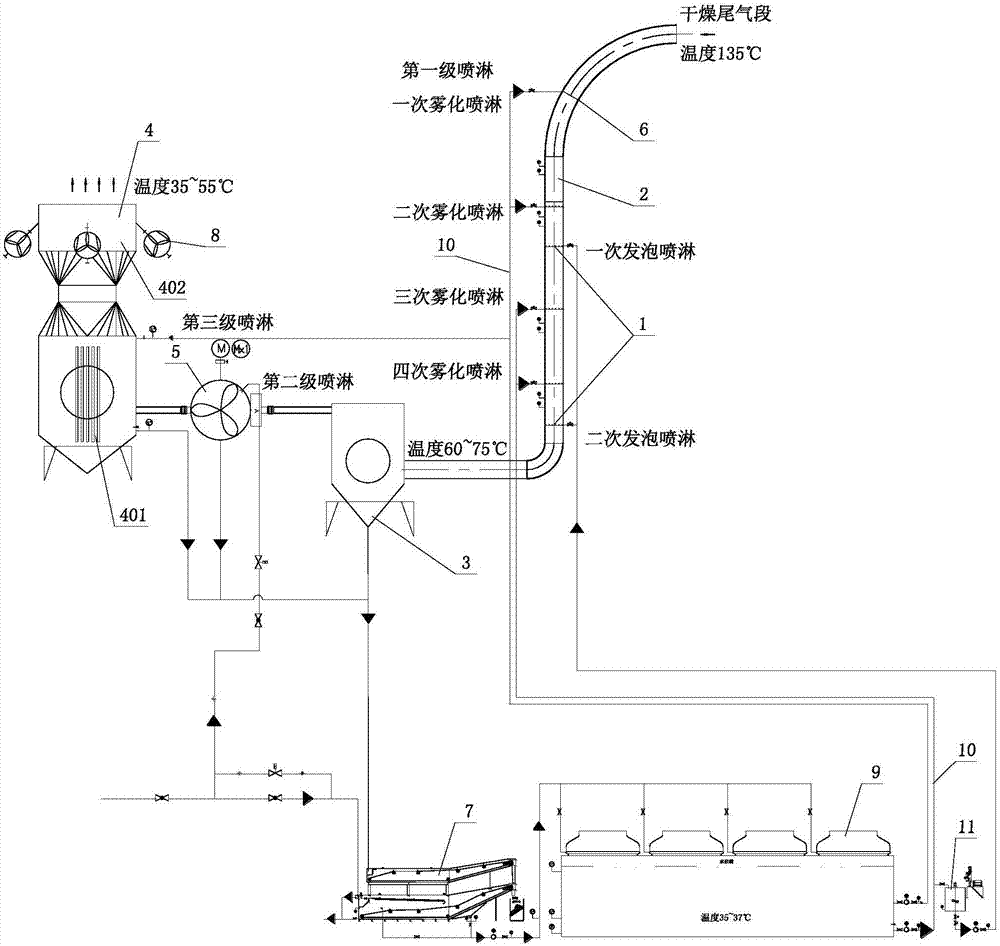

[0165] Such as figure 1 The shown processing system includes atomizing spray cooling pipeline 2 , drip cyclone separator 3 , induced draft fan 5 and exhaust chimney 4 connected in sequence.

[0166] The side wall of the atomizing spray cooling pipeline 2 is provided with a first-stage atomizing spray head 6, and the first-stage spraying includes four atomizing sprays, of which the first two atomizing sprays share one spraying pipeline , the last two atomization sprays share a spray pipeline to ensure that the spray pressure of the four atomization sprays is the same; below the first-stage spray head, there is a foaming nozzle 1, and the foaming spray It includes two foaming sprays, wherein the first foaming spray is located between the second atomized spray and the third atomized spray, and the second foamed spray is located downstream of the fourth atomized spray.

[0167] The drip cyclone separator 3 has a hollow cylindrical shape, and its bottom slag area is connected with...

Embodiment 2

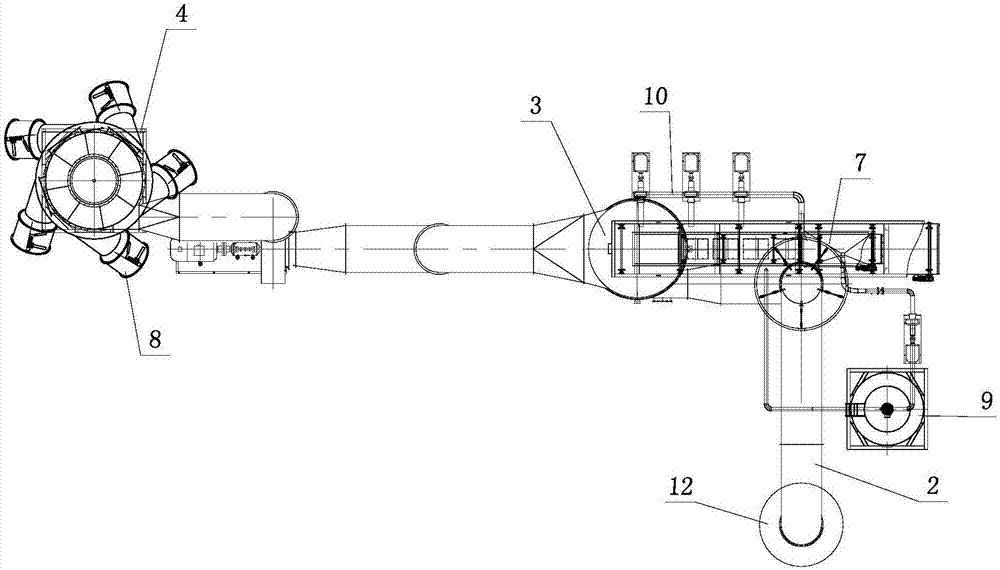

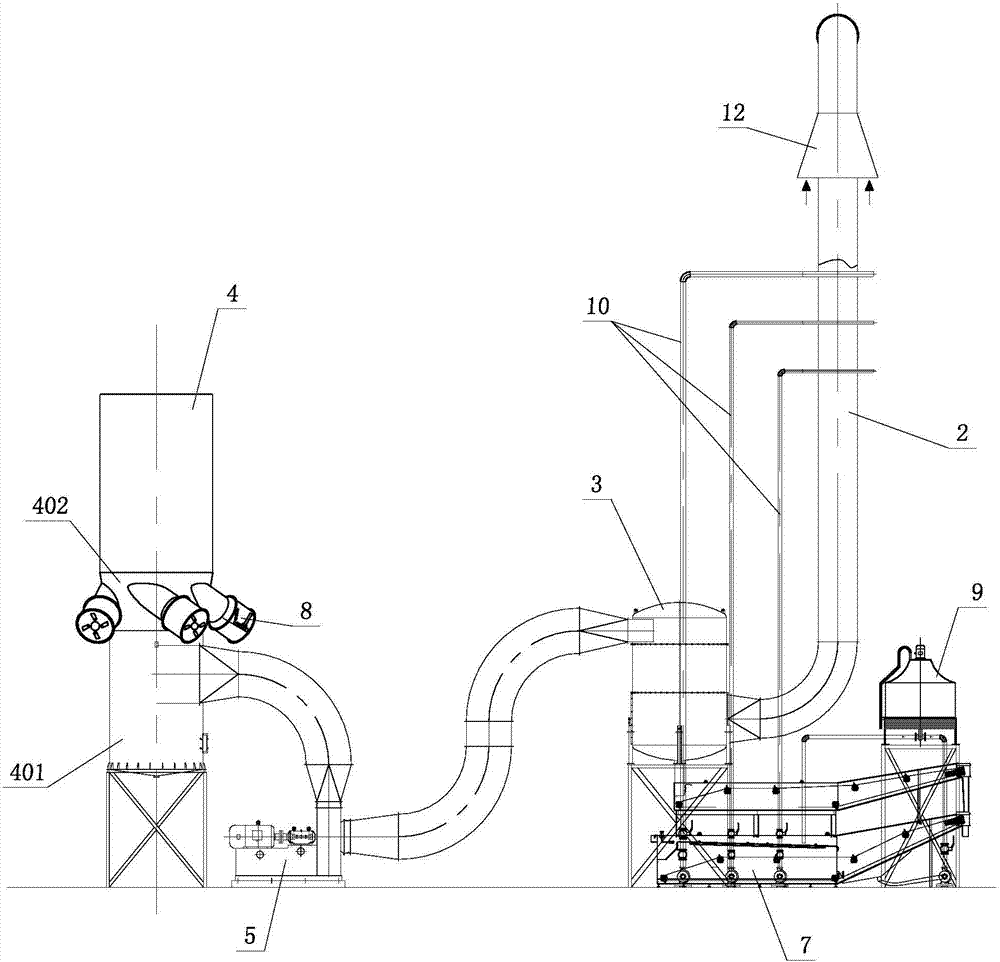

[0184] Such as Figure 2-4 The treatment system shown includes atomizing spray cooling pipeline 2, drip cyclone separator 3, induced draft fan 5 and exhaust chimney 4 connected in sequence, and some pipeline connections are omitted in the figure.

[0185] A conical wind cap 12 is arranged at the inlet of the atomizing spray cooling pipeline 2, the large and small ends of the conical wind cap are oriented in the same direction as the air intake direction of the atomizing spray cooling pipeline 2, and communicated with the atmosphere, and the small end of the conical wind cap is tightly fitted On the atomizing spray cooling pipeline 2 , an air supplement port is provided on the side wall of the atomizing spray cooling pipeline 2 in the small end.

[0186] There are three first-stage spray pipelines 10 on the side wall of the atomization spray cooling pipeline 2, corresponding to three atomization sprays, from top to bottom, the first spray water volume is 100-150m 3 / h, the sec...

Embodiment 3

[0199] Such as Figure 5As shown, the atomization spray cooling pipeline 2 has two sections of Venturi variable-diameter dust removal spray pipeline 201 connected in series. The variable-diameter dust-removing spray pipes 201 are connected by equal-diameter spray pipes 202; the first-stage atomizing spray heads 6 include three atomizing spray heads arranged at intervals along the exhaust gas traveling direction. Venturi variable-diameter dedusting spray pipe 201 corresponds to the variable-diameter pipe high-speed and high-pressure atomization spray cooling zone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com