Corrugated carton with dampproof and dustproof performance

A technology of corrugated box and corrugated cardboard, applied in the field of corrugated box, can solve the problems of complex production process, high cost, and need to improve the bonding strength, and achieve the effects of simple preparation process, improved adhesion level, and good water and moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

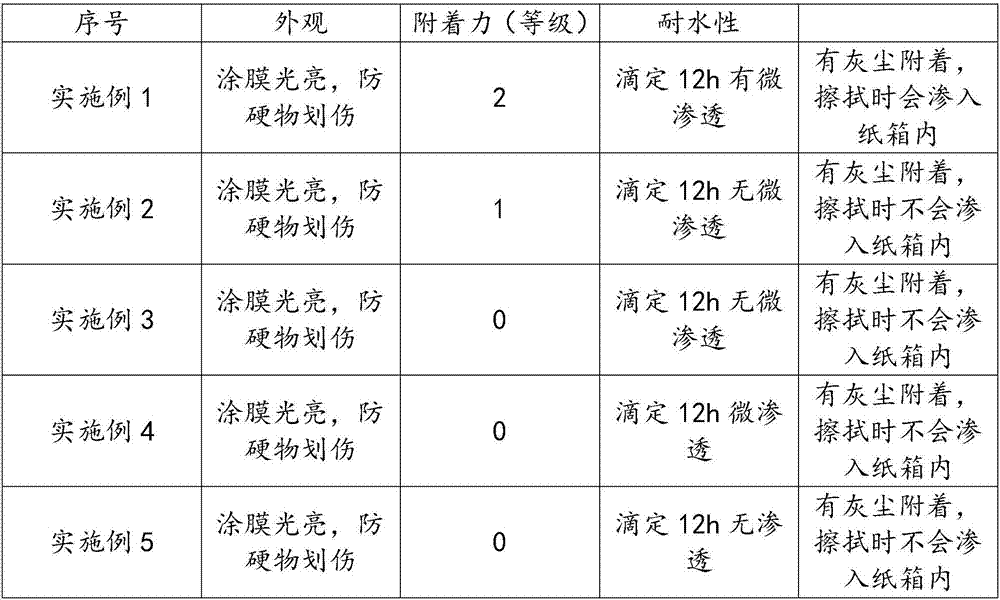

Examples

Embodiment 1

[0017] A corrugated cardboard box with moisture-proof and dust-proof properties, comprising corrugated cardboard, one surface of the corrugated cardboard is coated with a glazing agent, and the glazing agent includes the following components in parts by weight: 50 parts of ethanol, 3 parts of hard wax, poly 2 parts of dimethyl siloxane, 10 parts of methyl silicone oil, 6 parts of sodium hydroxide, 10 parts of acrylic resin;

[0018] The preparation method of the glazing agent of the present invention is: pour 50 parts of ethanol into the reaction kettle, and then add 3 parts of hard wax, 2 parts of polydimethylsiloxane, 10 parts of methyl silicone oil, 6 parts of sodium hydroxide and Add 10 parts of acrylic resin to the reaction kettle one after another, heat to dissolve and keep stirring, heat to 100-120°C for emulsification reaction for 1-5h; after the emulsification is complete, cool down naturally, and cool to room temperature to obtain the glazing agent.

Embodiment 2

[0020] A corrugated cardboard box with moisture-proof and dust-proof properties, comprising corrugated cardboard, one surface of the corrugated cardboard is coated with a glazing agent, and the glazing agent includes the following components in parts by weight: 50 parts of ethanol, 3 parts of hard wax, poly 4 parts of dimethyl siloxane, 15 parts of methyl silicone oil, 5 parts of sodium hydroxide, 8 parts of acrylic resin, 8 parts of rosin, 6 parts of oleic acid;

[0021] The preparation method of the glazing agent of the present invention is: pour 50 parts of ethanol into the reaction kettle, and then add 3 parts of hard wax, 4 parts of polydimethylsiloxane, 15 parts of methyl silicone oil, 5 parts of sodium hydroxide, Add 8 parts of acrylic resin and 8 parts of rosin into the reaction kettle successively, heat to dissolve and keep stirring; after the components in the reaction kettle are completely dissolved and mixed evenly, then add 6 parts of oleic acid and heat to 100-120...

Embodiment 3

[0023] A corrugated box with moisture-proof and dust-proof properties, comprising corrugated cardboard, one surface of the corrugated cardboard is coated with a glazing agent, and the glazing agent includes the following components in parts by weight: 50 parts of deionized water, 5 parts of hard wax , 2 parts of polydimethylsiloxane, 10 parts of methyl silicone oil, 6 parts of sodium hydroxide, 12 parts of acrylic resin, 10 parts of rosin, 3 parts of oleic acid;

[0024] The preparation method of the glazing agent of the present invention is: pour 50 parts of deionized water into the reaction kettle, and then 5 parts of hard wax, 2 parts of polydimethylsiloxane, 10 parts of methyl silicone oil, 6 parts of hydroxide Add sodium, 12 parts of acrylic resin and 10 parts of rosin into the reaction kettle successively, heat to dissolve and keep stirring; after the components in the reaction kettle are completely dissolved and mixed evenly, then add 3 parts of oleic acid and heat to 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com