Method for producing hydrogen through adsorbing, reinforcing and reforming glycerinum

A technology for reforming hydrogen and glycerin, applied in the energy field, can solve problems such as reduced efficiency, and achieve the effects of easy scale, stable hydrogen concentration, and stable breakthrough time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

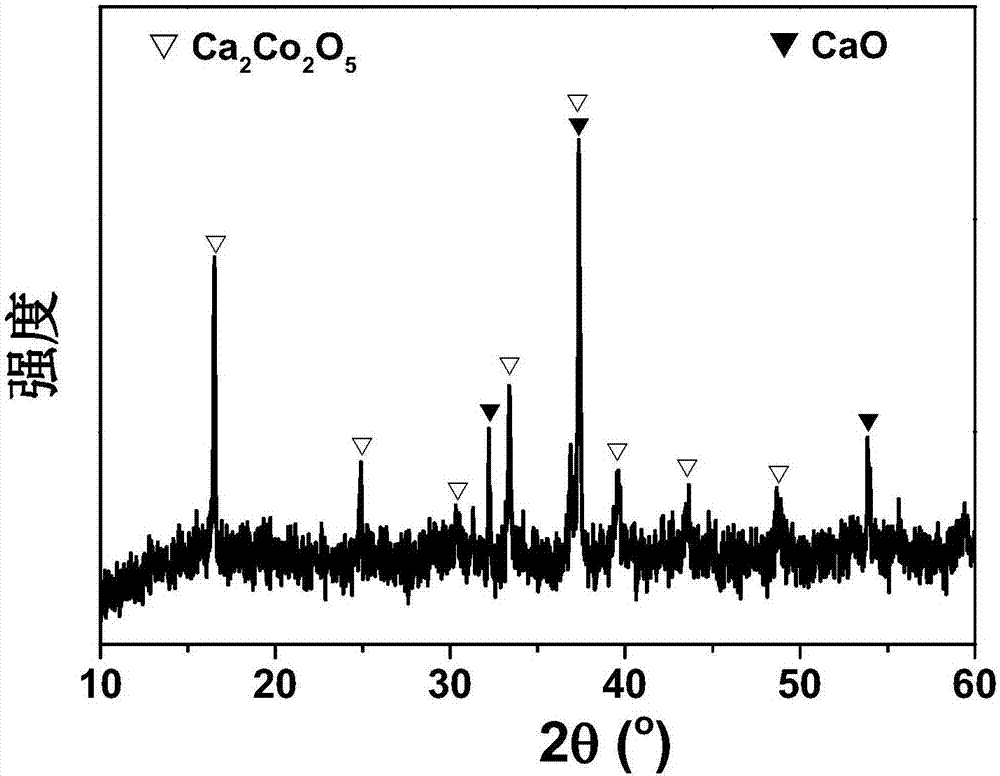

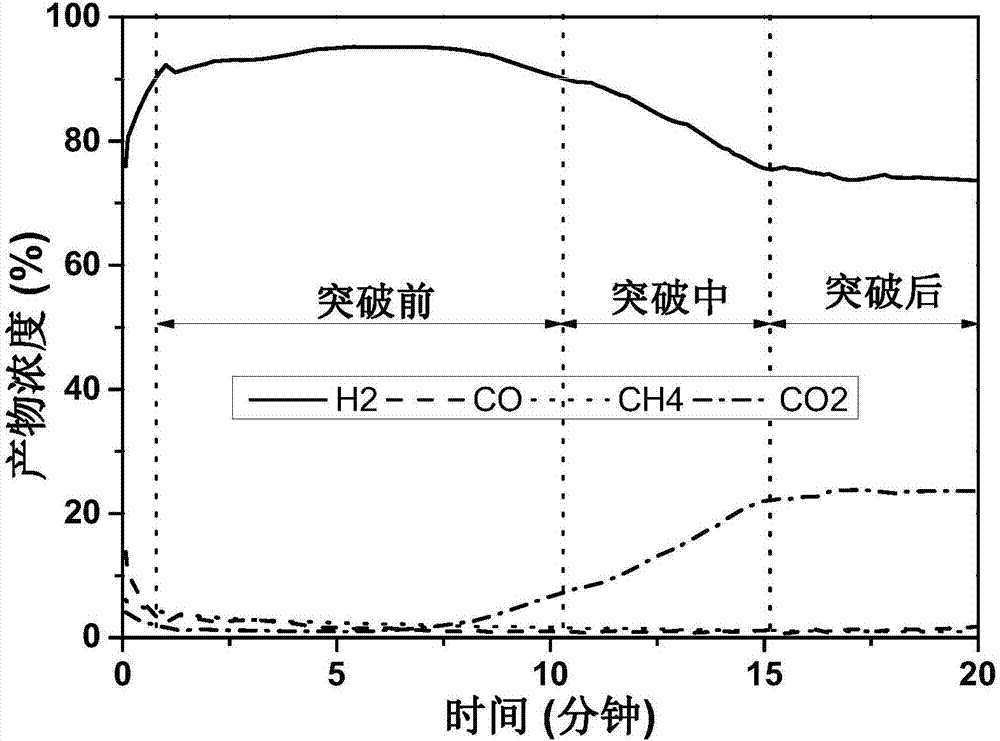

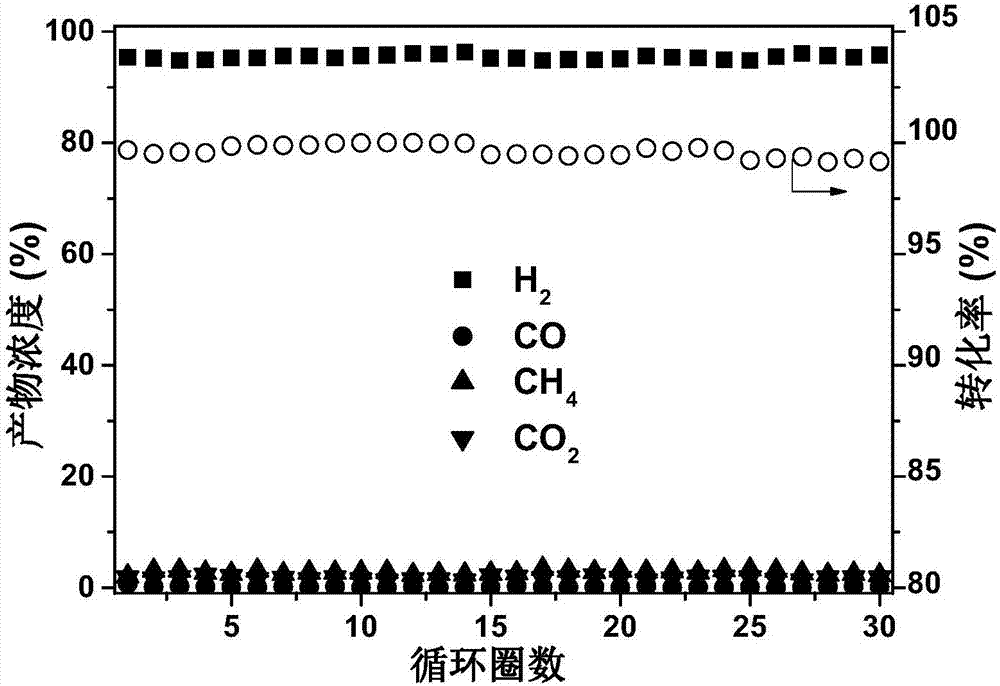

[0032] Calcium salt (0.02mol) and cobalt salt were weighed according to the ratio in Table 1, dissolved in 50ml of water, dried overnight at 120°C, and the obtained product was calcined at 800°C for 4h in a muffle furnace to obtain a Ca-Co-O catalyst. In the glycerin adsorption enhanced reforming reaction, the fixed bed reactor is filled with Ca-Co-O catalyst, nitrogen is used as carrier gas, and 0.262h -1 Glycerol-water mixture with a concentration of 0.328 g / mL was introduced at a weight hourly space velocity of 550°C. After GC detection, the concentration of hydrogen in the product after 5 minutes of reaction is shown in Table 1 below.

[0033] Table 1

[0034] Example

Embodiment 6-11

[0036] Calcium nitrate (0.02mol) and cobalt nitrate with a molar ratio of 1:1 were dissolved in 50ml of water, dried overnight at 120°C, and the resulting product was calcined in a muffle furnace under the conditions of Table 2 to obtain a Ca-Co-O catalyst. In the glycerin adsorption enhanced reforming reaction, the fixed bed reactor is filled with Ca-Co-O catalyst, nitrogen is used as carrier gas, and 0.262h -1 Glycerol-water mixture with a concentration of 0.328g / mL was passed through at a weight hourly space velocity, and the reaction temperature was 550°Cn. The results of the concentration of hydrogen in the product after 5 minutes of reaction are shown in Table 2 by GC detection.

[0037] Table 2

[0038]

Embodiment 12-14

[0040] Calcium nitrate (0.02mol) and cobalt nitrate with a molar ratio of 1:1 were dissolved in 50ml of water, dried overnight at 120°C, and calcined at 800°C for 4h in a muffle furnace to obtain a Ca-Co-O catalyst. In the glycerol adsorption enhanced reforming reaction, the fixed bed reactor is filled with Ca-Co-O catalyst, nitrogen is used as the carrier gas, and the glycerol-water mixture with a concentration of 0.328g / mL is passed through at the weight hourly space velocity in Table 3 , the reaction temperature is 550°C. The results of the concentration of hydrogen in the product after 5 minutes of reaction are shown in Table 3 by GC detection.

[0041] table 3

[0042] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com