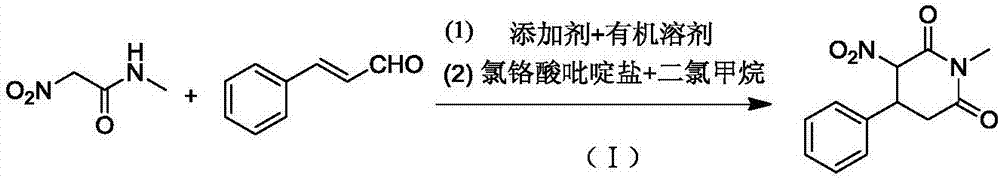

Method for synthesizing 1-methyl-3-nitro-4-phenyl-2, 6-dipiperidone

A technology of dipiperidone and methylnitroacetamide, applied in the direction of organic chemistry, can solve the problems of high cost of raw materials, cumbersome operation of synthesis methods, and high cost of synthesis, and achieve good diastereoselectivity and synthesis The effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 59mg (0.5mmol) of N-methylnitroacetamide, 89mg (0.65mmol) of cinnamaldehyde and 25mg (0.25mmol) of triethylamine solution into 4mL of methanol, stir at room temperature for 2 days; spin off the solvent and then react Add 10 mL of dichloromethane solution and 215 mg (1 mmol) of pyridinium chlorochromate to the system, and react for 16 hours. Post-processing: filter out the residue of pyridinium chlorochromate with a small amount of silica gel, and rinse 100 mL with petroleum ether: ethyl acetate = 2:1 After the solvent was spin-dried, it was directly separated by column chromatography to obtain 99 mg of racemic 1-methyl-3-nitro-4-phenyl-2,6-dipiperidone with a yield of 80%. The dr value is 70:1, the product is confirmed by NMR analysis, 1 H NMR(500MHz, CDCl 3 )δ7.42–7.32(m,3H), 7.25–7.20(m,2H), 5.62(d,J=12.0Hz,1H), 4.03(td,J=12.5,4.8Hz,1H), 3.27(s ,3H),3.17-2.91(m,2H). 13 C NMR(125MHz, CDCl 3 )δ168.68,163.59,135.25,129.63,129.10,126.70,90.53,40.13,37.27,27.57.

Embodiment 2

[0020] Add 59mg (0.5mmol) of N-methylnitroacetamide, 89mg (0.65mmol) of cinnamaldehyde and 43mg (0.65mmol) of lithium acetate into 4mL of methanol and stir at room temperature for 3 days; spin off the solvent and add to the reaction system Add 10 mL of dichloromethane solution and 215 mg (1 mmol) of pyridinium chlorochromate, and react for 16 hours. Post-processing: filter out the reaction residue of pyridinium chlorochromate with a small amount of silica gel, rinse 100 mL with petroleum ether: ethyl acetate = 2:1, and spin. After drying the solvent, it was directly separated by column chromatography to obtain 93 mg of racemic 1-methyl-3-nitro-4-phenyl-2,6-dipiperidone with a yield of 75%. The dr value is 50:1.

Embodiment 3

[0022] 120mg (1mmol) of N-methylnitroacetamide, 132mg (1mmol) of cinnamaldehyde and 30mg (0.3mmol) of triethylamine were added to 8mL of ethyl acetate and stirred at room temperature for 2 days; the solvent was spun off to the reaction system Add 20mL of dichloromethane solution and 430mg (2mmol) of pyridinium chlorochromate, and react for 16h. Post-processing: filter off the residue of the pyridinium chlorochromate with a small amount of silica gel, rinse 150mL with petroleum ether: ethyl acetate = 2:1, After the solvent was spin-dried, it was directly separated by column chromatography to obtain 175 mg of racemic 1-methyl-3-nitro-4-phenyl-2,6-dipiperidone with a yield of 70%. The dr value is 70:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com