Method for producing hydroxypropyl methylcellulose

A technology of hypromellose and production method, applied in chemical instruments and methods, mixers with rotary stirring devices, mixers, etc., can solve the problems of low reaction degree, high product yield, and high energy consumption for evaporation recovery , to achieve the effect of reducing energy consumption and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

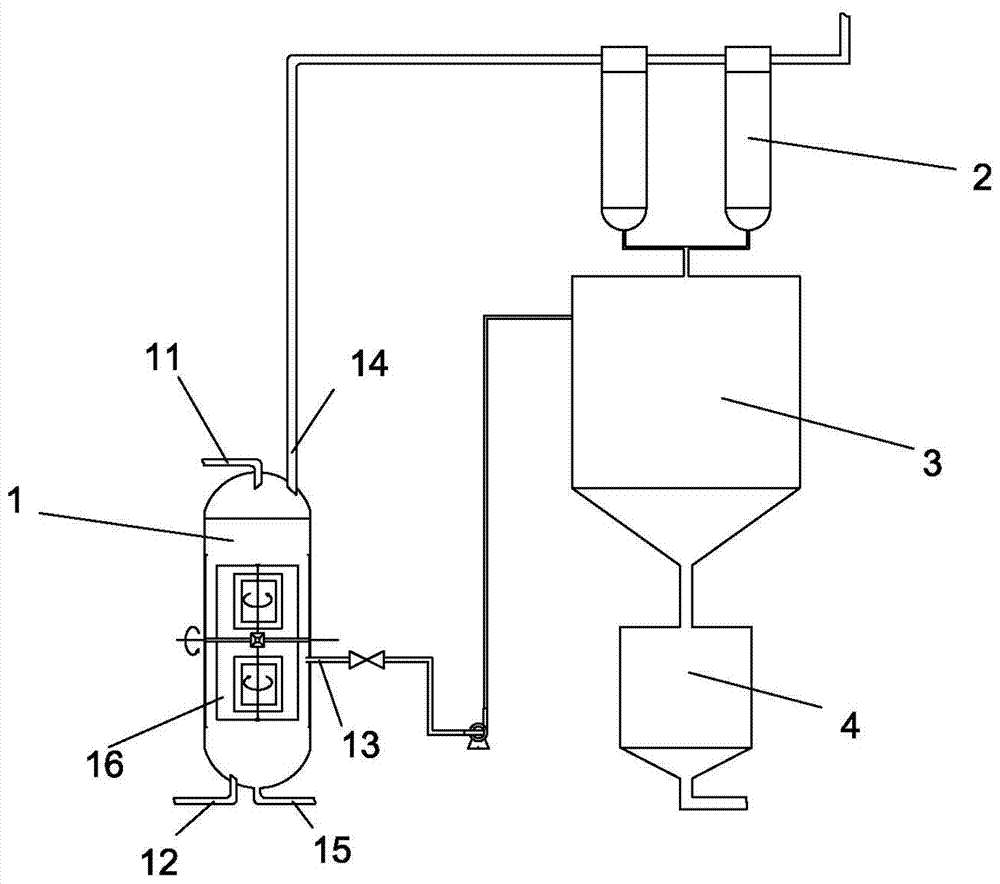

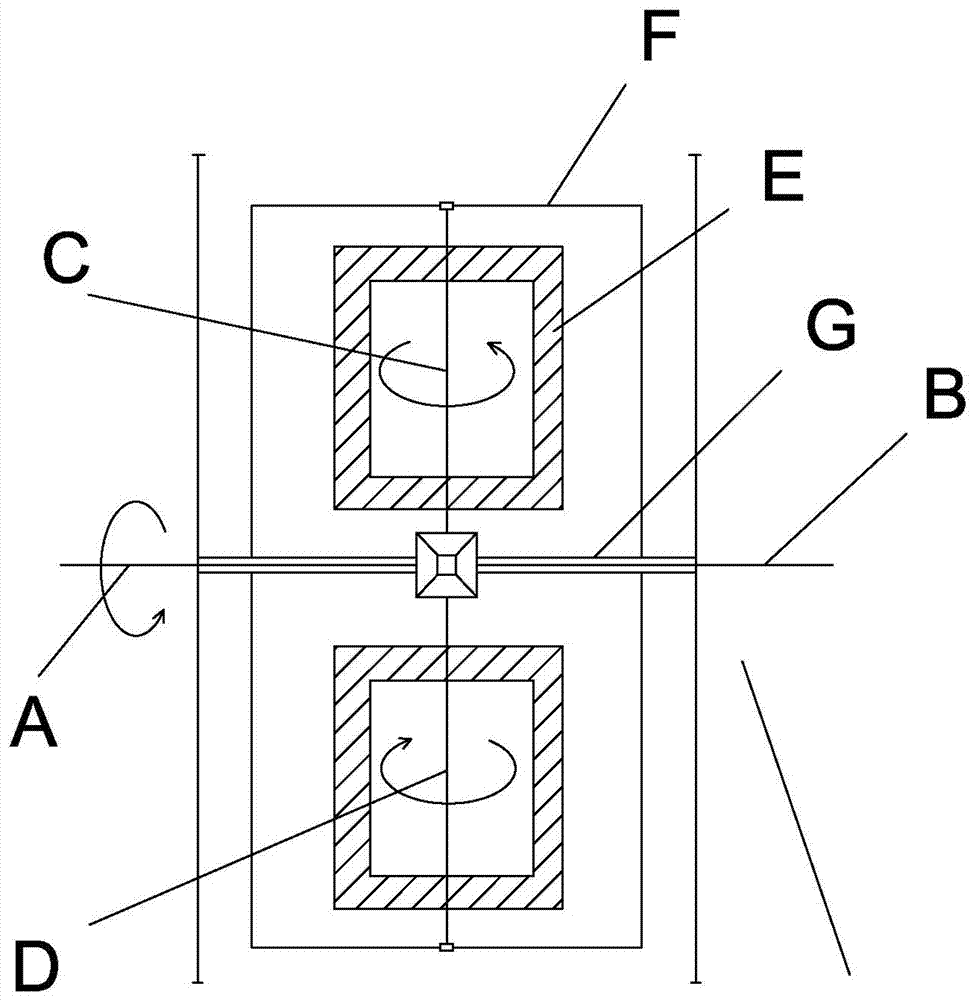

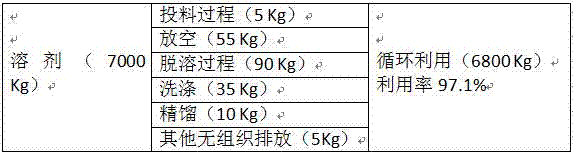

Method used

Image

Examples

Embodiment 1

[0033] 1. Pretreatment of cellulose raw materials

[0034] The refined cotton is crushed into refined cotton blocks with a diameter of about 1-3 cm by the cotton opener, and then enters the pulverizer, and is crushed into 60-100 mesh refined cotton powder by high-speed shearing.

[0035] The existing HPMC production process is to complete the pretreatment process of cellulose raw material - refined cotton through several steps such as opening, crushing, cyclone separation, bag dust removal and packaging.

[0036] The main source of pollution in this process is dust pollution, and the main source of dust is the tiny cellulose particles produced during the pulverization process, causing dust pollution in the air.

[0037] The dust generated in the two steps of unpacking and crushing in the whole pretreatment process is less. The opening step is to put the sheet-shaped refined cotton after manual unpacking on the opening machine, and tear it into loose pieces of 1-3 cm. This st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com