Hollow polymer microsphere profile control agent and preparation method thereof

A technology of polymer and profile control agent is applied in the field of profile control and preparation of hollow polymer microspheres, which can solve the problem of high cost and achieve the effect of improving utilization rate and reducing construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a hollow polymer microsphere profile control agent comprises the following contents: 1.5g Span-80, 0.1g azobisisobutyronitrile are dissolved in 10g divinylbenzene to prepare an oil phase emulsion, 1g acrylamide, 0.5g Sodium acrylate and 0.4g AES were dissolved in 100mL water to prepare an aqueous phase emulsion; 5mL of the aqueous phase emulsion was mixed with the oil phase emulsion, and after stirring for 30min, the remaining 95mL of the aqueous phase emulsion was mixed with the stirring rate at 150 rpm. Slowly add it, while raising the temperature to 70°C, and react for 3 hours; after the reaction, centrifuge the reaction solution at 6000 rpm, and the obtained solid is the hollow polymer microsphere profile control agent.

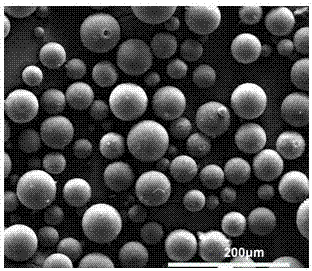

[0026] The scanning electron micrograph of this hollow polymer microsphere profile control agent is as follows figure 1 As shown, after determination, its average particle size is 41.32 μm.

Embodiment 2

[0028] A preparation method of a hollow polymer microsphere profile control agent comprises the following contents: 3g Span-60, 0.2g azobisisobutyronitrile are dissolved in 12g divinylbenzene to prepare an oil phase emulsion, 1.5g acrylamide, 1g2- Sodium acrylamide-2-methylpropane sulfonate and 0.6g AES were dissolved in 100mL water to prepare an aqueous phase emulsion; 3mL of the aqueous phase emulsion was mixed with the oil phase emulsion, and after stirring for 30min, the stirring rate was maintained at 200 rpm. In some cases, slowly add the remaining 97mL of aqueous phase emulsion into it, and at the same time raise the temperature to 70°C, and react for 5h; .

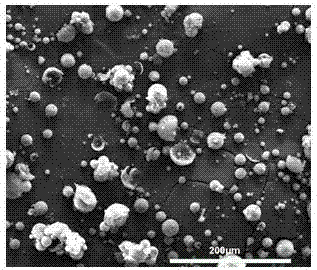

[0029] The scanning electron micrograph of this hollow polymer microsphere profile control agent is as follows figure 2 As shown, the average particle size was determined to be 29.17 μm.

Embodiment 3

[0031] A preparation method of a hollow polymer microsphere profile control agent comprises the following contents: 3g Span-80, 0.1g oil azobisisobutyronitrile are dissolved in 8g ethylene glycol dimethacrylate to prepare an oil phase emulsion, and 2g propylene Amide, 0.5g methacryloyloxyethyltrimethylammonium chloride and 0.6g AOS were dissolved in 100mL water to prepare a water phase emulsion; 4mL water phase emulsion was mixed with oil phase emulsion, and after stirring for 30min, the stirring rate was maintained at 200 In the case of constant rpm, slowly add the remaining 96mL of the aqueous phase emulsion, and at the same time raise the temperature to 70°C, and react for 3 hours; after the reaction, centrifuge the reaction solution at 6000 rpm, and the obtained solid is hollow polymerization Microsphere profile control agent.

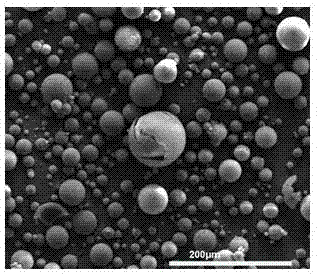

[0032] The scanning electron micrograph of this hollow polymer microsphere profile control agent is as follows image 3 As shown, the average par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com