A kind of active powder concrete product and preparation method thereof

A technology for concrete products and reactive powder, applied in the field of concrete, can solve the problems of unfavorable large-scale production of reactive powder concrete, difficult construction, poor fluidity, etc., and achieve the effects of easy processing, improved impermeability, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Refer to the following methods to prepare active powder concrete products and determine their fluidity, compression resistance and flexural resistance

[0053] 1. Material taking and weighing: According to the mixing ratio, use an electronic balance and a measuring cylinder to weigh the following raw materials respectively, with an allowable error of 0.1g:

[0054] 608g of cement, 98.8g of silica fume, 53.2g of fly ash, 154.3g of quartz sand, 231.5g of gold tailing sand, 716.6g of ordinary sand, 152ml of water, 13.7g of water reducing agent, and 124.8g of steel fiber, wherein the cement is Ordinary Portland cement (P.O42.5) produced by Xuanhua Jinyu Cement Co., Ltd., the particle size of the quartz sand is between 0.15 and 0.6mm, and the particle size of the gold tailing sand is between 0.075 and 0.3mm Between, the particle size of the ordinary sand is between 0.15 and 1.18mm, the water reducer is a polycarboxylate water reducer, the steel fiber is thin round, the surfa...

Embodiment 2~8

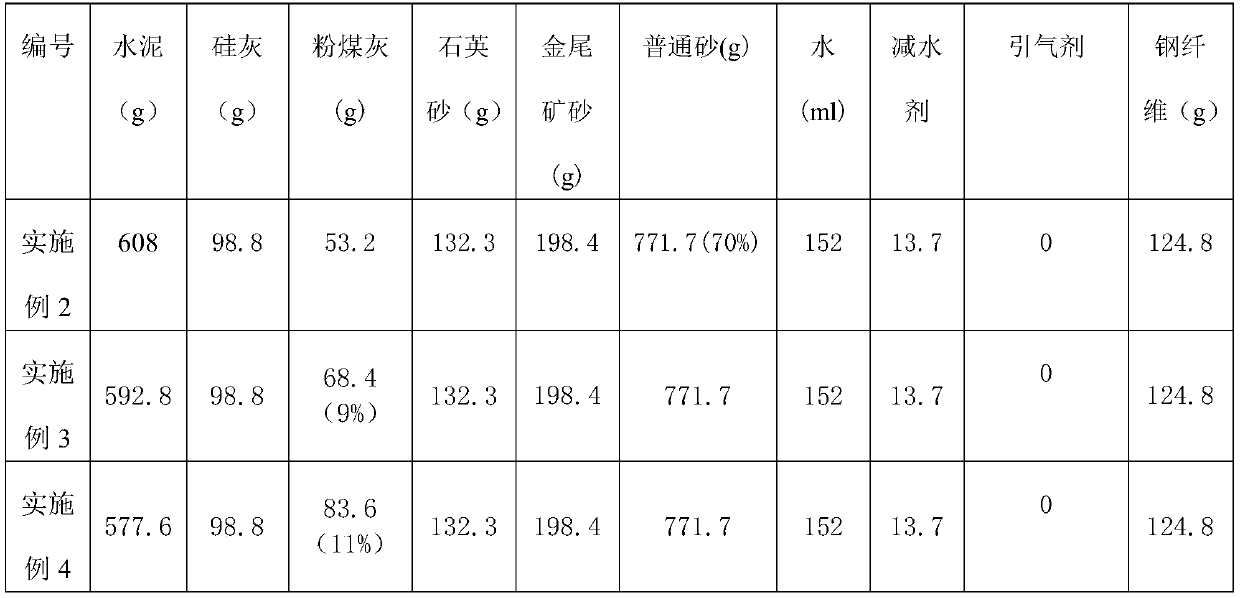

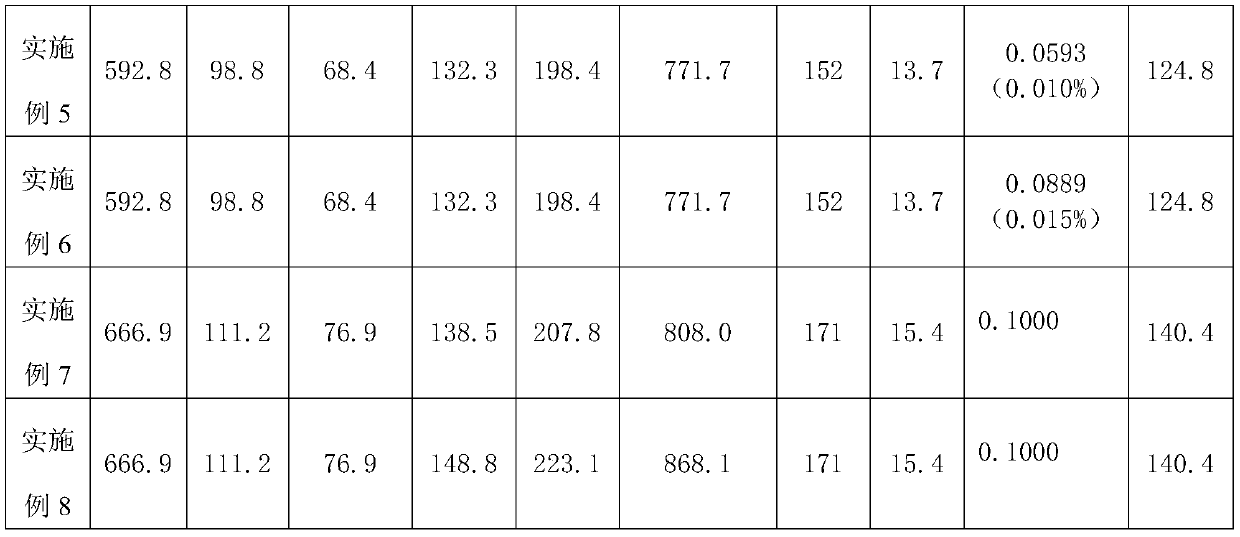

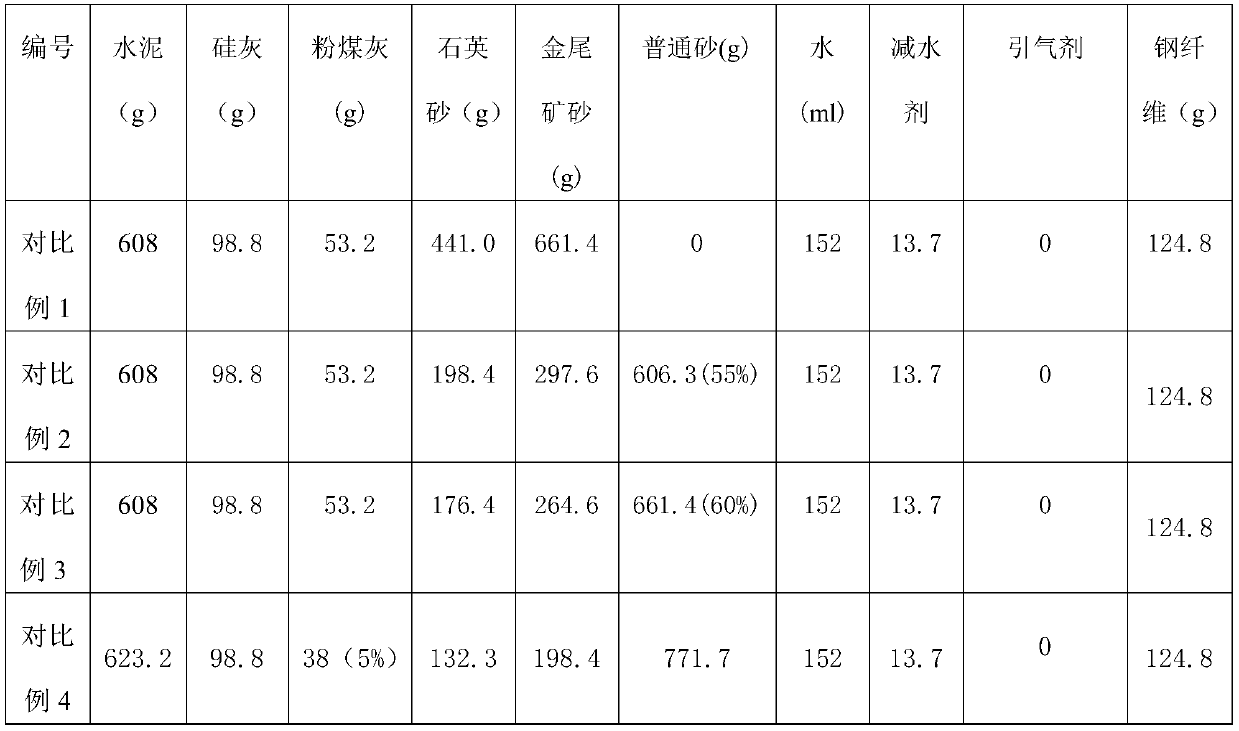

[0063] The reactive powder concrete of embodiment 2~8 is prepared with reference to the method described in embodiment 1, and detects its fluidity, compression resistance and flexure resistance, and its difference is only that the formula of each raw material is as shown in the following table:

[0064] The raw material ratio table of active powder concrete products described in table 1 embodiment 2~8

[0065]

[0066]

experiment example 1

[0072] Experimental Example 1 Determination of Optimum Dosage of Water Reducer

[0073] According to the compatibility experiment between water reducing agent and cement, the optimal dosage of water reducing agent is determined. The experimental results are shown in Table 3. It can be seen that the mass ratio of water reducing agent to gel material is in the range of 1.7-1.9:100 The internal flow is good, and the fluidity is the best when the mass ratio of the water reducer to the gel material is 1.8:100.

[0074] Table 3 cement compatibility test

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com