Polytetrafluoroethylene hydrophilic modification plasma treatment device and method

A technology of polytetrafluoroethylene and plasma, applied in the field of plasma, can solve problems such as environmental pollution, limited application, surface darkening, etc., achieve high-efficiency modification treatment effects, good flexibility and scalability, and meet modification needs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

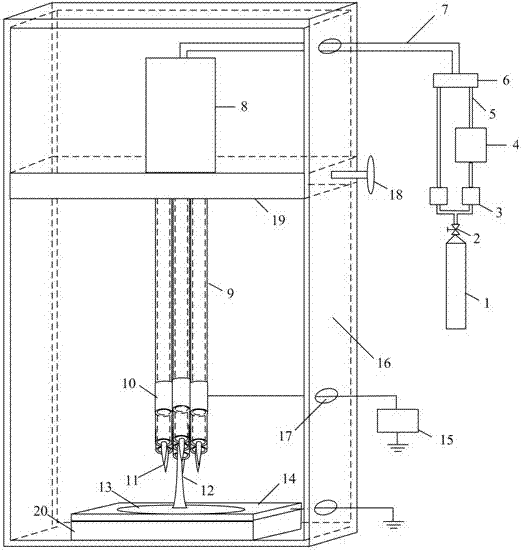

[0035] Polytetrafluoroethylene hydrophilic modified plasma treatment method, the method utilizes polytetrafluoroethylene hydrophilic modified plasma treatment device, specifically:

[0036] 1) Put the polytetrafluoroethylene 13 to be processed on the metal stage 14 from the front of the device box 16;

[0037] 2) The selected working gas is helium, the hydrophilic substance in the bubble bottle 4 is water, the voltage of the high-voltage power supply 15 is adjusted to 6kV, the frequency is fixed at 26 kHz, the high-voltage electrode 10 is connected to the high-voltage end of the high-voltage power supply 15, and the metal carrier The object platform 14 is a ground terminal;

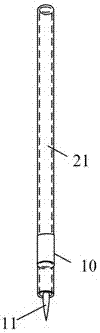

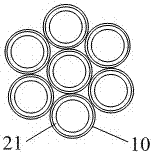

[0038] 3) Adjust the upper and lower positions of the unexpanded jet reactor 9, which is composed of 7 single-tube jet reactors 21, to a distance of 20 mm from the metal stage, and the gas flow rate is controlled at 4.5 L / min to form a high-intensity plasma jet , to complete the hydrophilic modification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com