Method for producing active antimicrobial substance HSAF by optimizing lysobacter enzymogenes OH11 with response surface method

A technology of producing lysobacterium lysobacterium and response surface method, which is applied in the field of optimizing the production of active antibacterial substance HSAF by lysobacterium lysobacterium OH11 by response surface method, which can solve the problem of low yield, large gap in industrial production level, and prevention of commercial promotion and application, etc. problem, to achieve the effect of low cost and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

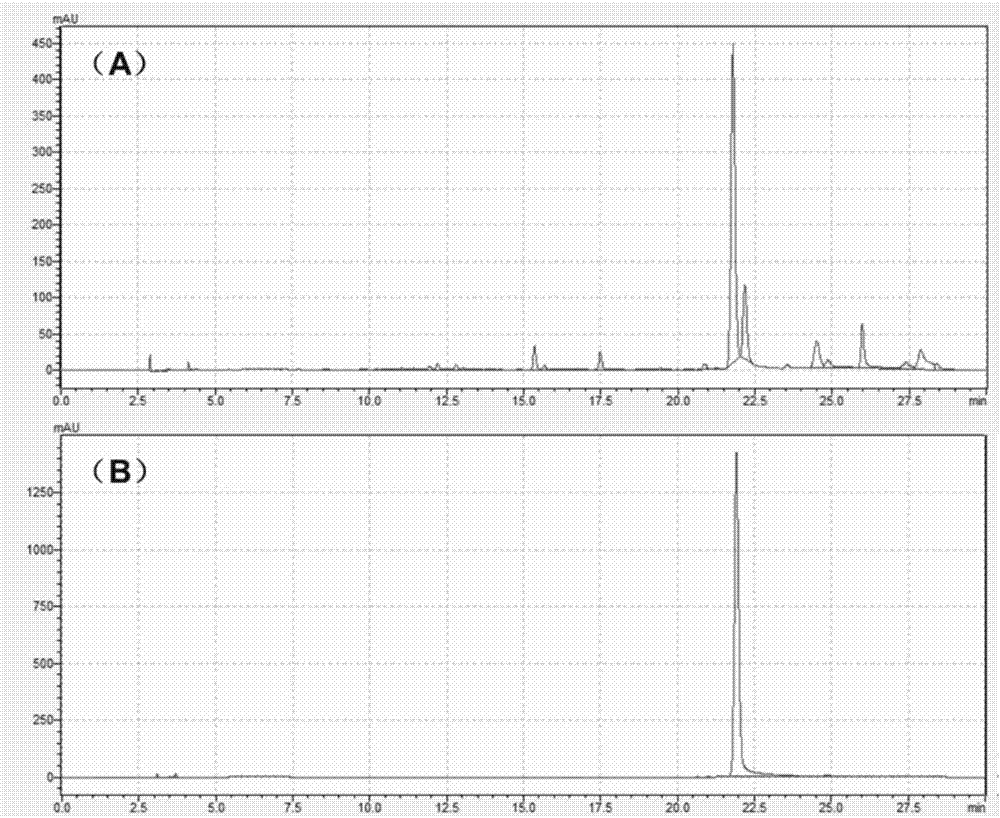

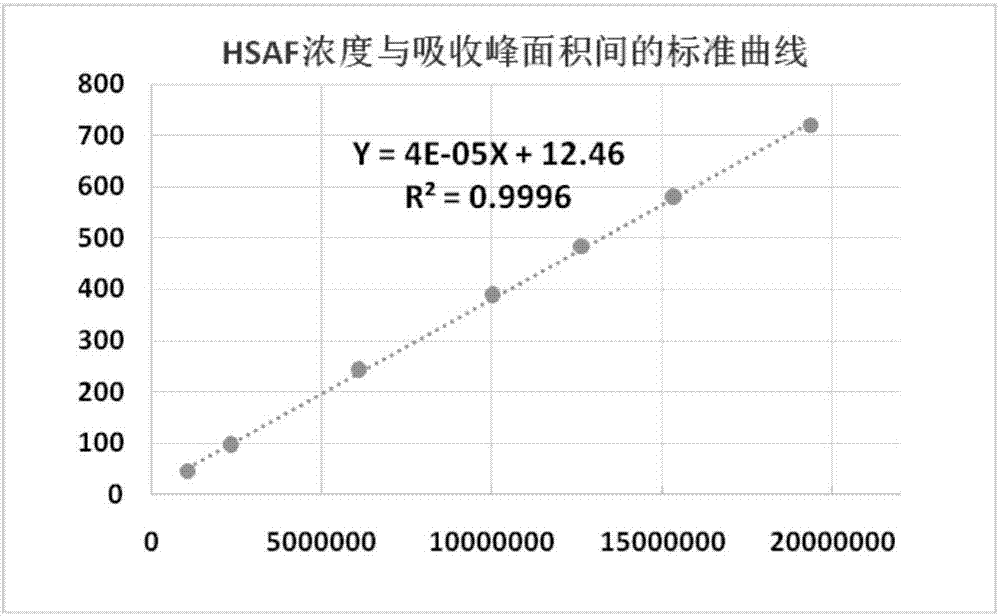

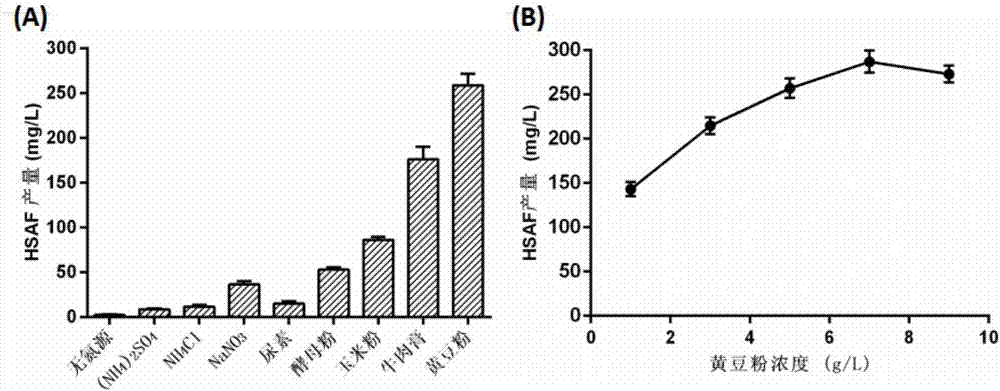

[0052] Embodiment 1: Single factor investigation of HSAF fermentation medium

[0053] Take out the glycerin tube of L.enzymogenesOH11 strain in the ultra-low temperature refrigerator at -80°C, melt it on ice, pour it into a strain bottle containing 5mL of LB culture solution, cultivate it overnight at 200rpm at 28°C, and dip the bacterial solution with an inoculation loop to draw on a solid plate Lines were cultured statically in a 30°C incubator for 2 days. Stretch the single colony strain on the plate in 50mL LB culture medium, shake and culture at 200rpm at 28°C for 12h to OD 600 =1.5, that is, the seed liquid is obtained.

[0054] According to the inoculum amount of 1.0%, it was inserted into the fermentation medium, cultured at 28° C. and 150 rpm for 48 hours, and three parallel experiments were set up for each group of experiments. The single factor test is carried out on 5g / L yeast powder, 2.5g / L glucose and 0.5g / L NaCl as the basic medium, only need to replace the co...

Embodiment 2

[0058] Embodiment 2: Optimization of HSAF fermentation medium

[0059] According to the single factor test, select the highest value as the center point of BBD test design (that is, 0 level), and establish the factor level table. And taking the concentration of L.enzymogenes OH11 metabolite HSAF as the response value, use Design Expert software to optimize according to the BBD design principle, as shown in Table 1.

[0060] Table 1 BBD test design and results of HSAF fermentation medium components

[0061]

[0062]

[0063] According to the response surface test results in Table 1, multiple regression fitting was carried out to obtain the effect of HSAF output in the fermentation broth on soybean flour (X 1 ), glucose (X 2 ), CaCl 2 (X 3 ) Concentration quadratic multiple regression fitting equation: Y=-334.00+67.50X 1 +6.25X 2 -36.25X 3 -10.00X 1 x 2 -5.00X 1 x 3 +22.50X 2 x 3 -69.75X 1 2 -97.25X 2 2 -52.25X 3 2 , R 2 = 0.9863.

[0064] Through the ...

Embodiment 3

[0065] Example 3 PB test screens significant influencing factors affecting HSAF shake flask fermentation

[0066]According to the fermentation characteristics of L.enzymogenesOH 11 and the research basis of our laboratory, 6 culture factors (inoculum volume, liquid volume, initial pH, culture temperature, shaker speed, fermentation cycle) were selected as the factors for the PB test investigation, and each factor was respectively Take two levels of high (+1) and low (-1), and design 12 groups of experiments with the concentration of HSAF in the fermentation broth as the response value, as shown in Table 2.

[0067] Using Design Expert software to carry out regression analysis on the PB test results, the order of significance of the influence of each fermentation factor on the concentration of HSAF is: fermentation period (X 6 )>Cultivation temperature (X 4 )>Liquid volume (X 2 )>Initial pH(X 3 )>Inoculation amount (X 1 )>Shaker speed (X 5 ); wherein the fermentation cycle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com