Method for improving ultrafiltration membrane flux of wood acidizing fluid

A technology of acidifying liquid and ultrafiltration membrane, applied in the production of sugar, xylose, sugar production, etc., can solve the problems of affecting the flux of ultrafiltration membrane, affecting product yield, increasing equipment investment, etc. Obstruction, easy operation, the effect of improving the flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

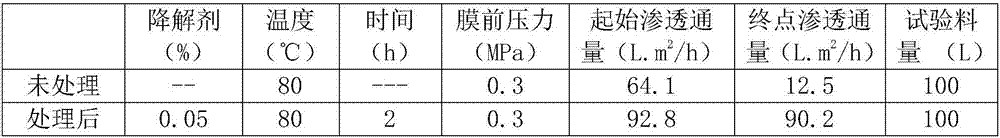

Embodiment 1

[0017] The method for improving the flux of the ultrafiltration membrane of the wood acidizing liquid of the present invention needs to degrade the wood acidizing liquid. Specifically, a degradation agent is added to the wood acidification solution to degrade the macromolecular substances in the wood acidification solution into small molecular substances, which can reduce the obstruction and improve the flux of the ultrafiltration membrane. The wood acidifying solution of the present invention degrades under acidic conditions, and the initial pH value of the degradation is 3-6, and the degradation initial pH value of the wood acidifying solution in this embodiment is 3.

[0018] The wood acidification solution of the present invention is the hydrolysis and acidification solution of wood, bamboo, bagasse or reed, and the wood acidification solution in this embodiment is eucalyptus hydrolysis and acidification solution. The degradation agent is one or more of peroxidase, laccase...

Embodiment 2

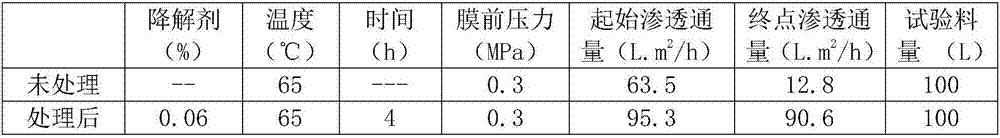

[0023] This example is basically the same as Example 1, except that the wood acidification solution used in this example is bamboo hydrolysis acidification solution, the degradation initial pH value is 4, the degradation time is 4 hours, and the degradation temperature is 65°C . The weight of the degradation agent is 0.06% of the weight of the wood acidification solution, and the degradation agent is a non-ionic surfactant OP-7. The comparison of the monosaccharide aqueous solution after the degradation treatment in this embodiment and the bamboo hydrolysis acidification solution without degradation treatment is shown in Table 2.

[0024]

[0025] Table II

Embodiment 3

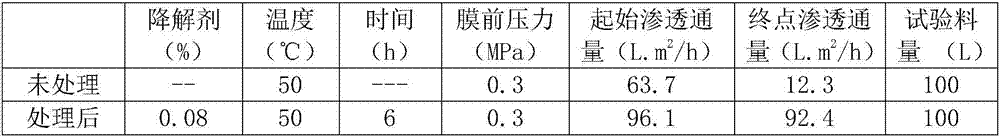

[0027] This example is basically the same as Example 1, except that the wood acidification solution used in this example is bagasse hydrolysis acidification solution, the degradation initial pH value is 5, the degradation time is 6 hours, and the degradation temperature is 50°C . The weight of the degrading agent is 0.08% of the weight of the wood acidifying solution, and the degrading agent is composed of sodium lauryl sulphate and pingpingjia. The comparison of the monosaccharide aqueous solution after the degradation treatment in this embodiment and the bamboo hydrolysis acidification solution without degradation treatment is shown in Table 3.

[0028]

[0029] Table three

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com