A kind of diaphragm for lithium ion battery and preparation method thereof

A lithium-ion battery and separator technology, applied in the field of lithium-ion battery separators and their preparation, can solve the problems of electrode damage, inability to prepare ultra-thin ceramic separators, multi-coating amount, etc., and achieve improved energy density and good electrochemical stability. The effect of improving the tensile strength and puncture strength of fluid absorption and storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

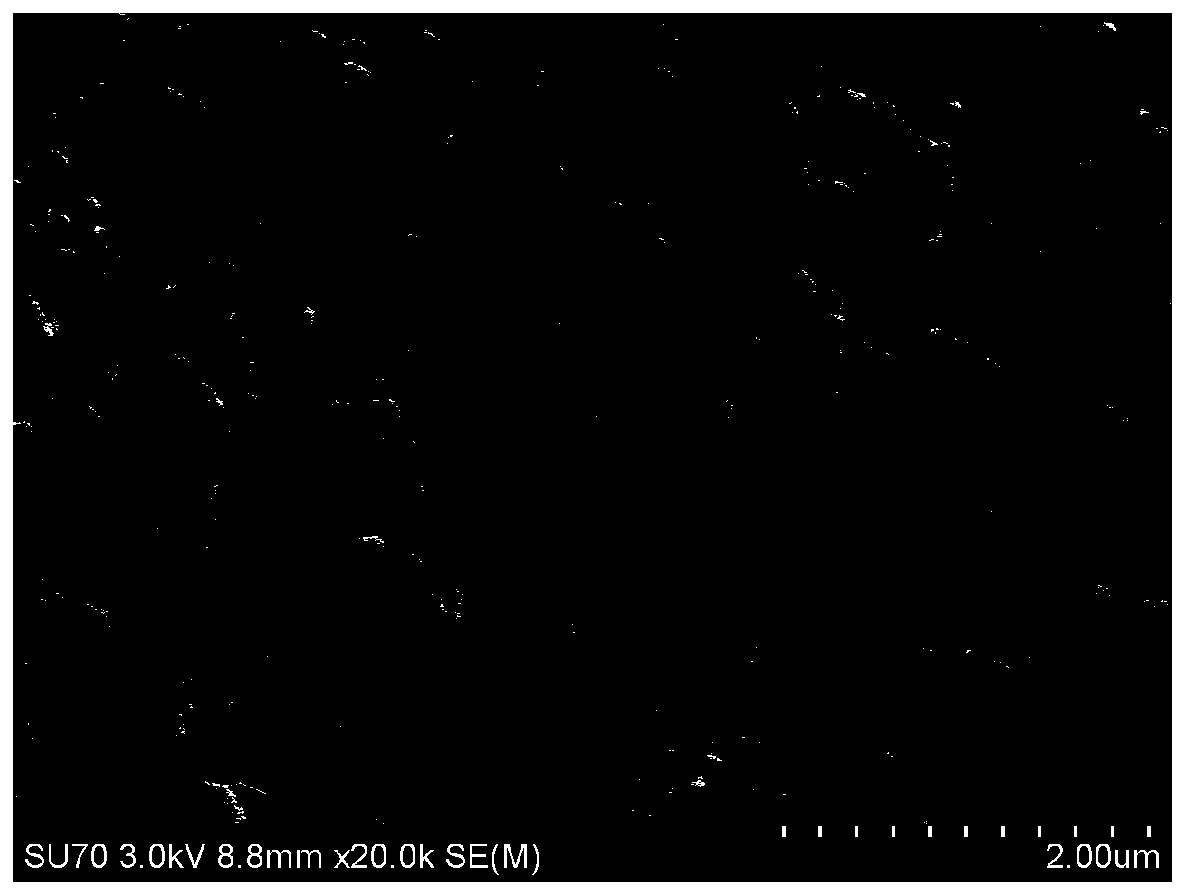

Image

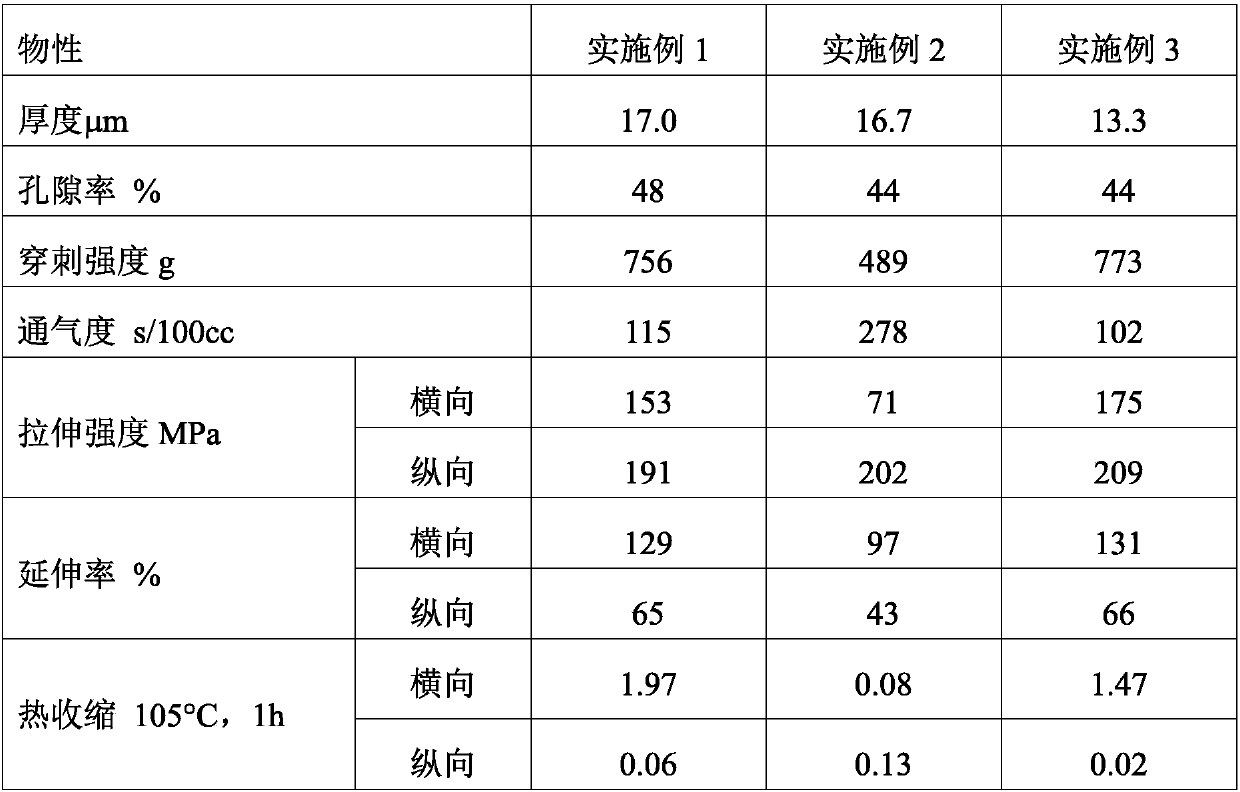

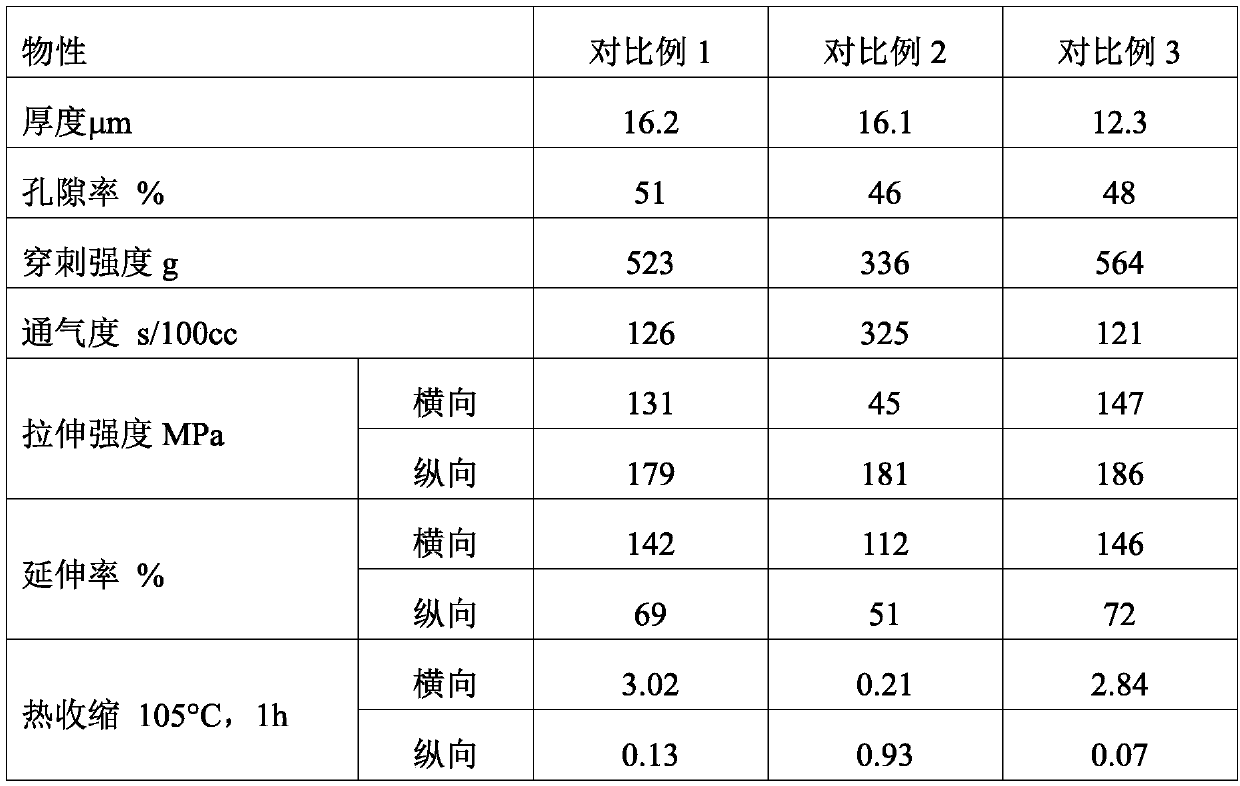

Examples

Embodiment 1

[0042] (1) 3wt.%AlCl 3 ·6H 2 O with 97wt.% Al 2 o 3 ·H 2 O nanometer fine scales were mixed, added 5wt.% deionized water, and the mechanical ball milling was 5 hours under the rotating speed of 450rpm, to Al 2 o 3 ·H 2 Surface modification of O nanoscale fine scales, the surface modified Al 2 o 3 ·H 2 O nano fine scales have good hydrophilicity and good dispersion in deionized water medium;

[0043] (2) Surface modified Al 2 o 3 ·H 2 O nanometer fine scales are added to the mixed aqueous solution with a concentration of 10wt.% CMC and 5wt.% SBR, and the surface modification Al 2 o 3 ·H 2 The solid content of O nanometer fine flakes in the slurry is 55wt.%, stirred and mixed into a uniform slurry at a temperature of 40° C.;

[0044] (3) Continuously extrude and coat the above-mentioned slurry on the surface of one side of a wet-process PE base film with a porosity of 51% and a thickness of 16.2 μm, and dry continuously at an oven temperature of 75-105°C at a dryi...

Embodiment 2

[0048] (1) 4wt.% AlCl 3 ·6H 2 O with 96wt.% Al 2 o 3 ·H 2 O nanofibers were mixed, added with 8wt.% deionized water, and mechanically milled at 450rpm for 5 hours. 2 o 3 ·H 2 O nanofibers for surface modification. Surface modified Al 2 o 3 ·H 2 O nanofibers have good hydrophilicity and good dispersion in deionized water medium;

[0049] (2) Surface modified Al 2 o 3 ·H 2 O nanofibers were added to a mixed aqueous solution with a concentration of 10wt.% CMC and 5wt.% SBR, and the surface was modified by Al 2 o 3 ·H 2 The solid content of O nanofibers in the slurry is 60wt.%, stirred and mixed into a uniform slurry at a temperature of 40°C;

[0050] (3) Continuously extrude and coat the above-mentioned slurry on one surface of a dry-process PP base film with a porosity of 46% and a thickness of 16.1 μm, and dry continuously at an oven temperature of 75-105° C. at a drying speed of 40 m / min. Deionized water volatilizes and forms pores, and Al is modified after dr...

Embodiment 3

[0053] (1) 6wt.% AlCl 3 ·6H 2 O with 94wt.% Al 2 o 3 ·H 2 O nanometer fine scales were mixed, added 10wt.% deionized water, and mechanically milled for 5 hours at a speed of 450rpm, to Al 2 o 3 ·H 2 O nanoscale fine scales for surface modification. Surface modified Al 2 o 3 ·H 2 O nano fine scales have good hydrophilicity and good dispersion in deionized water medium;

[0054] (2) Surface modified Al 2 o 3 ·H 2 O nanometer fine scales are added to the mixed aqueous solution with a concentration of 10wt.% CMC and 5wt.% SBR, and the surface modification Al 2 o 3 ·H 2 The solid content of the O nanometer fine scales in the slurry is 65wt.%, stirred and mixed into a uniform slurry at a temperature of 40° C.;

[0055] (3) Continuously extrude and coat the above slurry on one surface of a wet-process PE base film with a porosity of 48% and a thickness of 12.3 μm, and dry continuously at an oven temperature of 75-105°C at a drying speed of 40m / min. Deionized water vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com