Lithium-rich manganese based composite material, preparation method and application thereof

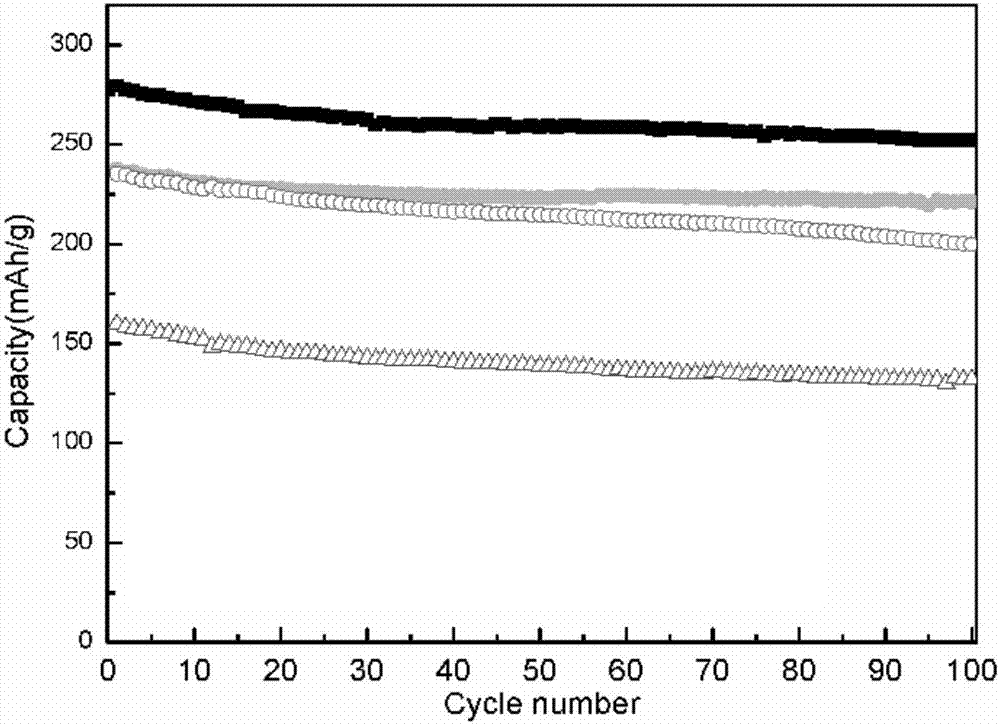

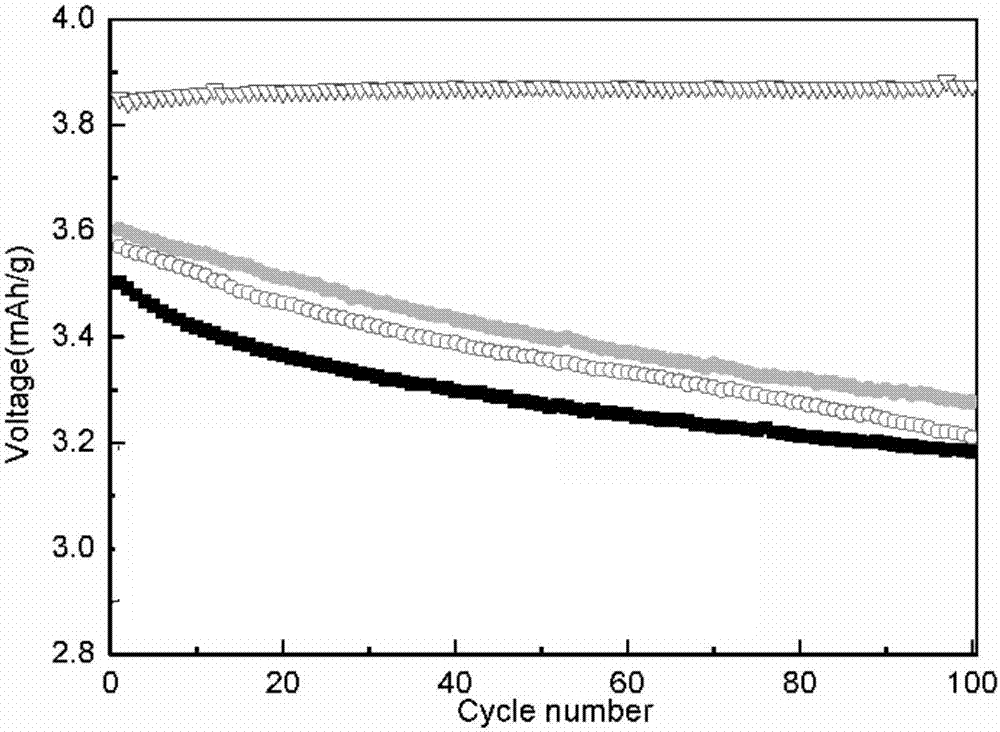

A technology of lithium-rich manganese-based and composite materials, which is applied in the field of lithium-ion batteries, can solve the problems of high material phase requirements, complex process, and no obvious improvement in voltage drop of lithium-rich manganese-based positive electrode materials, so as to improve cycle performance and voltage Attenuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present application also provides a method for preparing a lithium-rich manganese-based composite material as shown in formula (I), comprising the following steps:

[0040] Mixing the material shown in formula (II), the lithium-rich manganese-based material shown in formula (III) and an additive to obtain a mixed material, the additive is selected from one of citric acid, glucose, chitosan and sucrose one or more kinds;

[0041] heat-treating the mixed material to obtain a lithium-rich manganese-based composite material as shown in formula (I);

[0042] Li α Z β (PO 4 ) γ / xLi 2 MnO 3 ·(1-x)LiMO 2 (I);

[0043] Li α Z β (PO 4 ) γ (II);

[0044] wxya 2 MnO 3 ·(1-x)LiMO 2 (Ⅲ);

[0045] Among them, 1≤α≤3, 1≤β≤2, 1≤γ≤3, α, β and γ are natural numbers;

[0046] Z is selected from one or more of V, Ni and Co;

[0047] 0

[0048] Li mentioned in this application α Z β (PO 4 ) γ with xLi 2...

Embodiment 1

[0057] (1) 0.7kg lithium-rich manganese-based material 0.4Li 2 MnO 3 0.6LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , 0.3kg triclinic Li 3 V 2 (PO 4 ) 3 Mix with 30g glucose for 3h using a mixer mill to obtain a mixed material;

[0058] (2) Place the above mixed material in an argon protective atmosphere, and anneal at 400° C. for 3 hours to obtain a lithium-rich manganese-based composite positive electrode material with the general formula (IV);

[0059] Li 3 V 2 (PO 4 ) 3 / 0.4Li 2 MnO 3 0.6LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 (Ⅳ).

Embodiment 2

[0061] (1) 0.5kg lithium-rich manganese-based material 0.4Li 2 MnO 3 0.6LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , 0.5kg triclinic Li 3 V 2 (PO 4 ) 3 Mix 3h with 40g chitosan with a mixer mill to obtain a mixed material;

[0062] (2) placing the above mixed material in an argon protective atmosphere, annealing at 450° C. for 3 hours to obtain a lithium-rich manganese-based composite cathode material with the general formula (IV);

[0063] Li3 V 2 (PO 4 ) 3 / 0.4Li 2 MnO 3 0.6LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 (Ⅳ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com