Method for eliminating deformation of fraxinus mandshurica wood

A technology of wood deformation and ash, applied in wood treatment, impregnation of wood, wood impregnation, etc., can solve the problem of easy deformation of ash wood, improve surface wettability and infiltration uniformity, eliminate deformation, improve The effect of load strength and load uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

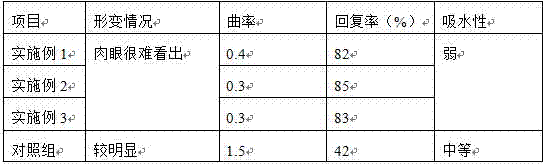

Examples

Embodiment 1

[0016] A method for eliminating the deformation of Fraxinus mandshurica wood includes the following steps:

[0017] (1) Put the freshly cut ash wood in an oven preheated at 100°C, and dry it until the quality is constant. The drying setting temperature is 2°C per hour. After drying, take out the wood and place it at temperature Soak in the dipping solution at 50℃ for 2 hours. The dipping solution is made of the following components in terms of mass percentage: polybutyl methacrylate emulsion accounts for 3.5%, dehydrated trisitol trioleate accounts for 2.4%, and vinyl acetate accounts for 1.2 %, tributyl phosphate accounted for 0.6%, carboxymethyl cellulose accounted for 0.4%, sodium bicarbonate accounted for 0.2%, ammonium persulfate accounted for 0.1%, and the remainder was water;

[0018] (2) Take out the soaked wood, dry the surface dipping liquid, dry it for 2 days and then bake it on a slow fire. The temperature is controlled at 110°C until the weight is constant. Then the wo...

Embodiment 2

[0025] A method for eliminating the deformation of Fraxinus mandshurica wood includes the following steps:

[0026] (1) Put the freshly cut Fraxinus mandshurica wood in an oven preheated at 102°C, and dry it until the quality is constant. The drying setting temperature is 2°C per hour. After drying, take out the wood and place it at temperature. It is immersed in the impregnating solution at 55℃ for 2.5 hours. The impregnating solution is made of the following ingredients in terms of mass percentage: polybutyl methacrylate emulsion accounts for 3.7%, dehydrated trisitol trioleate accounts for 2.5%, and vinyl acetate accounts for 1.3 %, tributyl phosphate accounts for 0.7%, carboxymethyl cellulose accounts for 0.5%, sodium bicarbonate accounts for 0.25%, ammonium persulfate accounts for 0.2%, and the remainder is water;

[0027] (2) Take out the soaked wood, dry the surface dipping liquid, dry it for 2 days and then bake it on a slow fire. The temperature is controlled at 115°C unti...

Embodiment 3

[0034] A method for eliminating the deformation of Fraxinus mandshurica wood includes the following steps:

[0035] (1) Put the freshly cut Fraxinus mandshurica wood in an oven preheated at 105°C, and dry it until the quality is constant. The setting temperature for drying is 3°C per hour. After drying, take out the wood and place it at temperature It is immersed in an immersion solution at 60°C for 3 hours. The immersion solution is made of the following components in terms of mass percentage: polybutyl methacrylate emulsion accounts for 4.0%, trisitol trioleate accounts for 2.6%, and vinyl acetate accounts for 1.4 %, tributyl phosphate accounted for 0.8%, carboxymethyl cellulose accounted for 0.6%, sodium bicarbonate accounted for 0.3%, ammonium persulfate accounted for 0.3%, and the remainder was water;

[0036] (2) Take out the soaked wood, dry the surface dipping liquid, dry it for 3 days and then bake it on a slow fire. The temperature is controlled at 120°C until the weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com