A kind of synthetic method of modified sulfamate water reducer

A technology of sulfamate and synthesis method, which is applied in the field of synthesis of modified sulfamate water reducer, can solve the problems of high raw material price, poor water retention performance, high production cost, etc., to reduce production cost and maintain collapse Excellent performance, the effect of improving water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

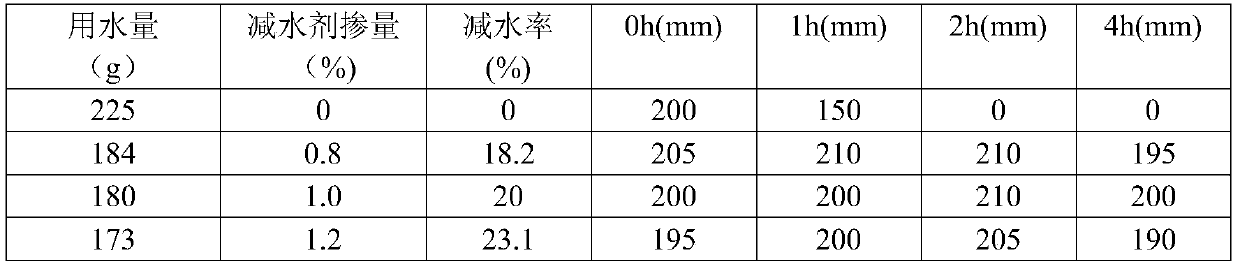

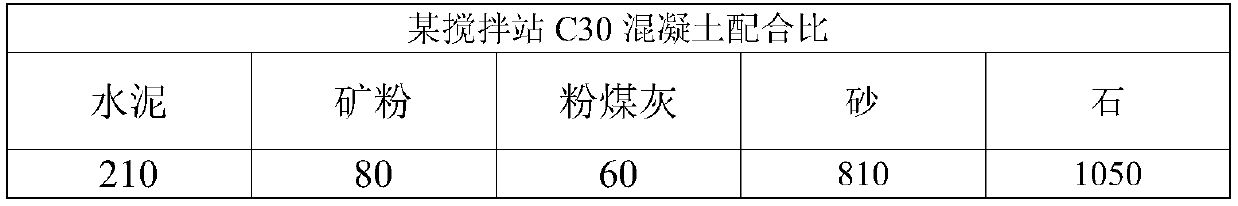

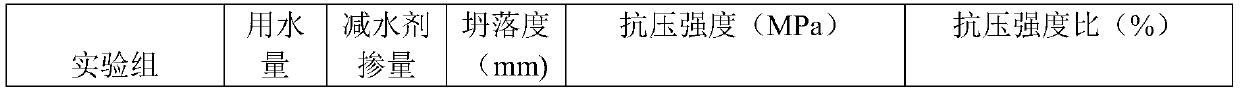

Method used

Image

Examples

Embodiment 1

[0019] A kind of synthetic method of modified sulfamate water reducer, comprises the steps:

[0020] (1) The weight ratio of raw materials is: sodium p-aminobenzenesulfonate 17.37%; phenol 7.07%; formaldehyde 21.9%; sodium hydroxide 0.26%; urea 1.56%; melamine 14.6%; water 37.24%;

[0021] (2) Methylolation of melamine: put 85g of water, 97.4g of melamine, and 52.5g of formaldehyde into the reaction kettle A, heat up to 60°C, after the melamine is completely dissolved, continue the reaction for 15 minutes and then terminate the reaction;

[0022] (3) Dissolution and neutralization: Weigh 92.5g of water, 115.6g of sodium p-aminobenzenesulfonate, and 47g of phenol into the reactor and stir to raise the temperature to 73°C; weigh 1.5g of sodium hydroxide and dissolve it in 20g of water; dissolve the sodium hydroxide solution Add to the reaction kettle and stir for 15 minutes;

[0023] (4) Hydroxymethylation condensation: Weigh 93.2g formaldehyde solution (the mass fraction of th...

Embodiment 2

[0026] A kind of synthetic method of modified sulfamate water reducer, comprises the steps:

[0027] (1) The weight ratio of raw materials is: 18.9% of sodium p-aminobenzenesulfonate; 9.1% of phenol; 25.3% of formaldehyde; 0.33% of sodium hydroxide; 0.93% of urea; 15.9% of melamine;

[0028] (2) Methylolation of melamine: put 80g of water, 97.4g of melamine, and 52.5g of formaldehyde into the reaction kettle A, heat up to 60°C, after the melamine is completely dissolved, continue the reaction for 15 minutes and then terminate the reaction;

[0029] (3) Dissolving and neutralizing: Weigh 87.5g of water, 115.6g of sodium p-aminobenzenesulfonate, and 67.7g of phenol into the reactor and stir to raise the temperature to 73°C; weigh 1.8g of sodium hydroxide and dissolve it in 10g of water; The solution was added to the reaction kettle and stirred for 15 minutes;

[0030] (4) Hydroxymethylation condensation: Weigh 102.5g formaldehyde solution (the mass fraction of the formaldehyde ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com