Preparation method of high-color-rendering white phosphor for 3D (three-dimensional) printing

A 3D printing and high color rendering technology, applied in chemical instruments and methods, luminescent materials, climate sustainability, etc., can solve problems such as short device life and difficulty in forming LED light-emitting layers, achieving high precision and accurate and detailed data , the effect of advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with accompanying drawing:

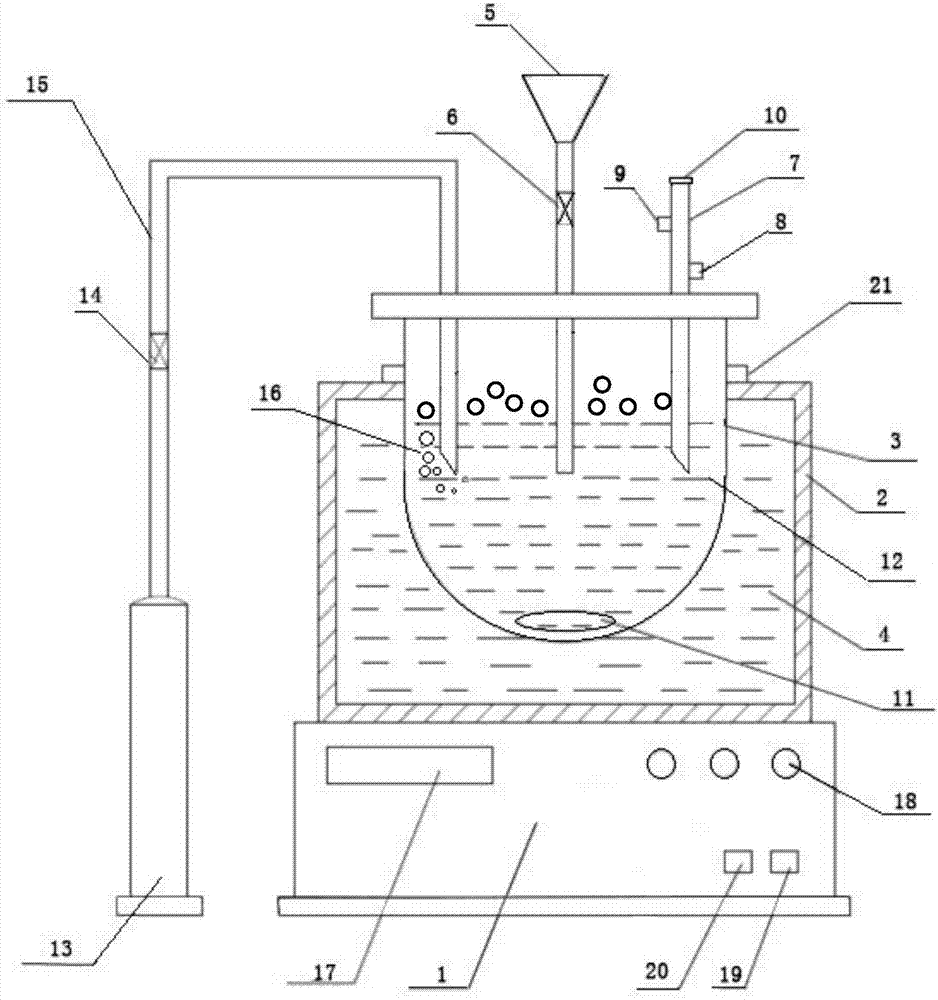

[0077] figure 1 As shown, the state diagram for the preparation of the polymer, the position of each part must be correct, the proportion should be proportioned, and the operations should be performed in sequence.

[0078] Quantities of chemicals used in preparation are determined in pre-set ranges in grams, milliliters, centimeters 3 is the unit of measurement.

[0079] The preparation of the polymer is carried out in a three-necked flask, which is completed in a water bath, heating, magnetic stirring, nitrogen protection, and water circulation condensation;

[0080] The electric heater 1 is vertical, and the upper part of the electric heater 1 is a water bath 2, and the upper part of the water bath 2 is a three-necked flask 3, which is fixed by a fixing seat 21. The water bath 2 is a water bath 4, and the water bath 4 needs Submerge 4 / 5 of the volume of the three-necke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com