Method for testing content of aluminum ions in aluminum etching liquid

A test method, aluminum etching technology, applied in the direction of material electrochemical variables, chemical analysis by titration, etc., can solve the problems of large error of results, increase of test cost, complex matrix interference, etc., to achieve low price, small test cost, The effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

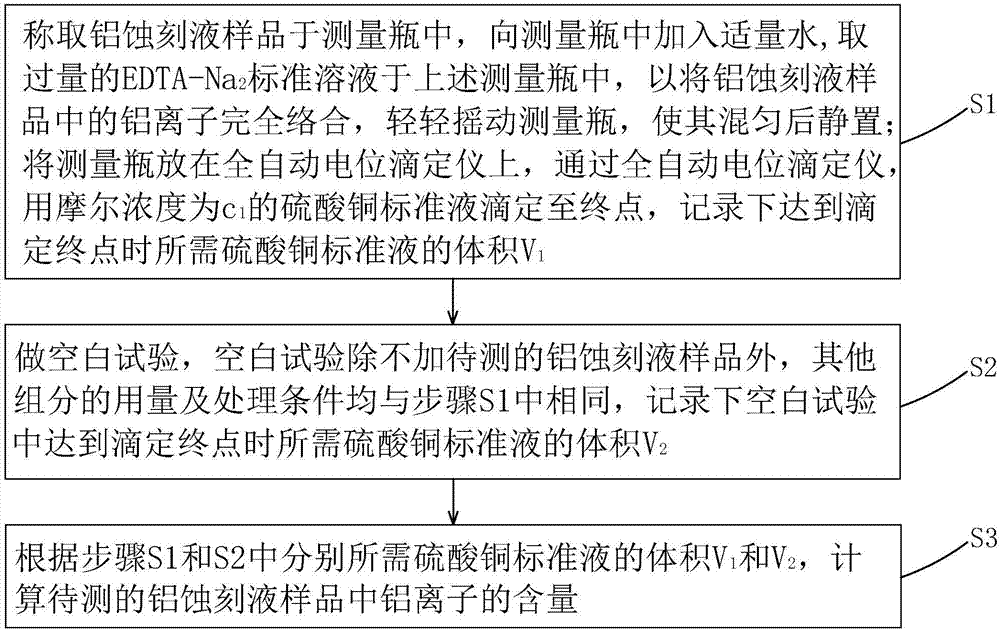

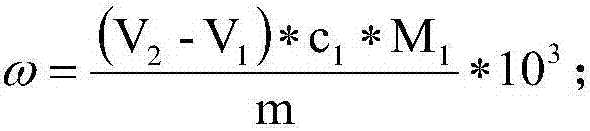

[0033] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0034] see figure 1 , the invention provides a kind of testing method of aluminum ion content in the aluminum etching solution, adopts automatic potentiometric titrator automatic titration, at first utilizes disodium ethylenediaminetetraacetic acid (EDTA-Na 2 ) and aluminum ions (Al 3+ ) complexation reaction, take excess EDTA-Na 2 The solution completely complexes the aluminum ions in the aluminum etching solution sample, and its reaction formula is as follows (1):

[0035] EDTA-Na 2 +Al 3+ →(EDTA-Al) + +2Na + (1);

[0036] Then back titrate the excess EDTA-Na with copper sulfate standard solution 2 , the reaction formula is as follows (2):

[0037] EDTA-Na 2 +Cu 2+ →EDTA-Cu+2Na + (2);

[0038] When the automatic potentiometric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com