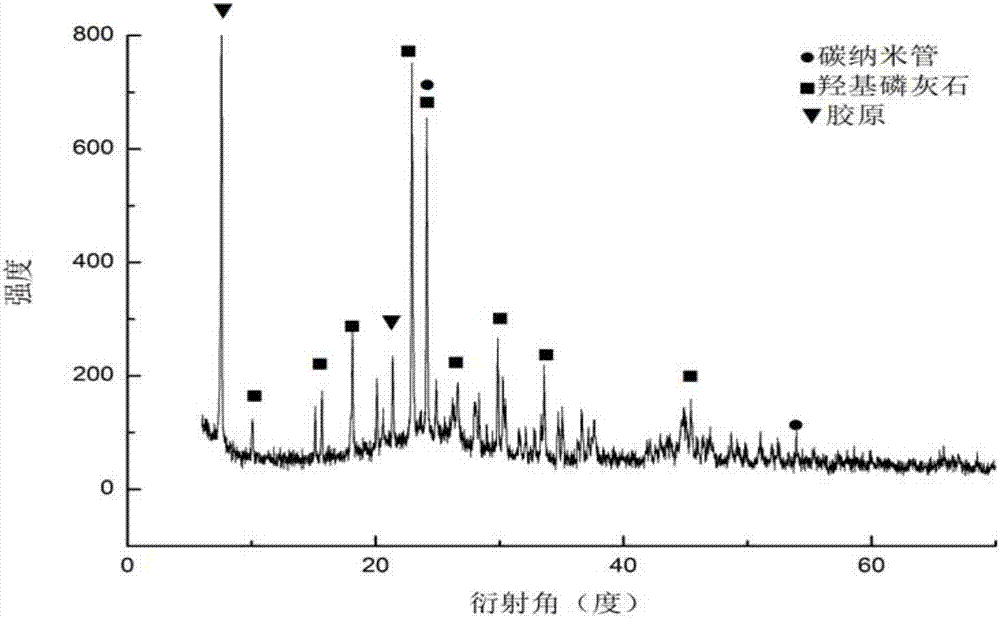

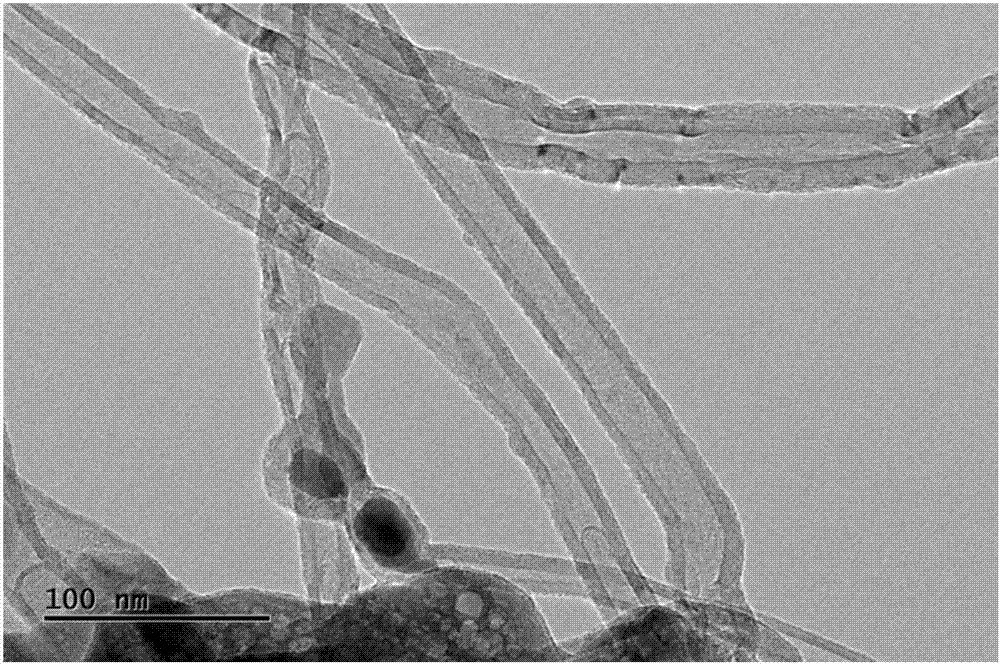

Preparation method of composite carbon nano tube reinforced hydroxyapatite material

A technology of hydroxyapatite and carbon nanotubes, applied in the field of phosphate-based compositions, can solve the problems of low interfacial bonding strength, toxicity, and risks, and achieve good reinforcement and toughening, and excellent mechanical properties. , to avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The first step is to prepare carbon nanotube-hydroxyapatite composite powder:

[0035]Weigh the required mass of ferric chloride hexahydrate and hydroxyapatite particles with a particle size of 10nm at a mass ratio of 0.55:1, and mix the weighed The hydroxyapatite particles were added to deionized water to form a hydroxyapatite suspension with a molar concentration of 0.01mol / L, and then the weighed ferric chloride hexahydrate was added to the above-mentioned hydroxyapatite suspension, and stirred 2h, ferric chloride is uniformly impregnated in hydroxyapatite to obtain suspension I, suspension I: 25% (mass percentage) ammonia water=100:1 in volume ratio, add 25% (mass percentage) to above suspension I percentage) of ammonia water, and continue to stir for 1 hour to obtain suspension II, place the formed suspension II in an ultrasonic disperser, and disperse ultrasonically at a frequency of 20 kHz for 40 min to fully react ferric chloride and ammonia water to form Fe(OH)...

Embodiment 2

[0048] The first step is to prepare carbon nanotube-hydroxyapatite composite powder:

[0049] Weigh the required mass of ferric chloride hexahydrate and hydroxyapatite particles with a particle size of 40nm in a mass ratio of 1.2:1, and mix the weighed ferric chloride hexahydrate with a mechanical stirrer at a speed of 250r / min. The hydroxyapatite particles were added to deionized water to form a hydroxyapatite suspension with a molar concentration of 0.15mol / L, and then the weighed ferric chloride hexahydrate was added to the above-mentioned hydroxyapatite suspension, and stirred 3h, ferric chloride is uniformly impregnated in the hydroxyapatite to obtain the suspension I, the suspension I: 25% (mass percentage) ammonia water=60:1 in the volume ratio, add 25% (mass percentage) to the above suspension I percentage) of ammonia water, and continue to stir for 2.5 hours to obtain suspension II. Place the formed suspension II in an ultrasonic disperser, and ultrasonically disperse...

Embodiment 3

[0057] The first step is to prepare carbon nanotube-hydroxyapatite composite powder:

[0058] Weigh the required mass of ferric chloride hexahydrate and hydroxyapatite particles with a particle size of 60nm according to the ratio of 1.75:1 in mass ratio, and under the condition of stirring at a speed of 400r / min with a mechanical stirrer, the weighed The hydroxyapatite particles were added to deionized water to form a hydroxyapatite suspension with a molar concentration of 0.3mol / L, and then the weighed ferric chloride hexahydrate was added to the above-mentioned hydroxyapatite suspension, and stirred 4h, ferric chloride is uniformly impregnated in hydroxyapatite to obtain suspension I, suspension I: 25% (mass percentage) ammonia water=20:1 in volume ratio, add 25% (mass percentage) to above-mentioned suspension I percentage) of ammonia water, and continue to stir for 4 hours to obtain suspension II, place the formed suspension II in an ultrasonic disperser, and disperse it by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com