Production process for C-shaped-opening cylindrical shell with threshold buckling unloading self-resetting function

A manufacturing process and a technology for cylindrical shells, which are applied in the field of manufacturing processes of C-shaped open cylindrical shells, can solve the problems of inability to meet the use requirements of recoverable structures, poor elastic performance, and low bearing capacity of C-shaped shells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

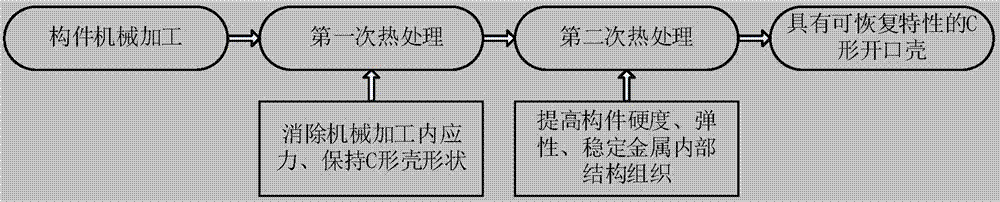

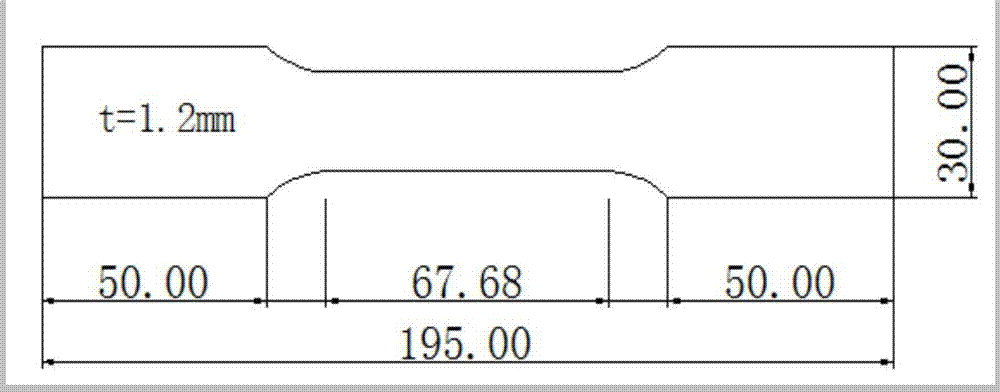

[0024] The technological process of the C-shaped open cylindrical shell with self-resetting function mainly includes: mechanical processing technology and heat treatment technology. refer to figure 1 , the specific production process is, steel plate rolling or mold casting → drilling after forming → high temperature overheating → normalizing → low temperature tempering → high temperature overheating → quenching (oil cooling) → medium temperature tempering → natural cooling. The C-shaped shell member is made of manganese steel with grade 65, and the thickness of the steel plate is 1.2mm. First, according to figure 2 Manufacture 6 pieces of corresponding tensile members as shown, and then make a C-shaped shell according to the following heat treatment process, of which 3 pieces of tensile members and C-shaped shells have the same heat treatment process, and the other 3 pieces of tensile members are not subjected to heat treatment as a comparison . Described technological proc...

Embodiment 2

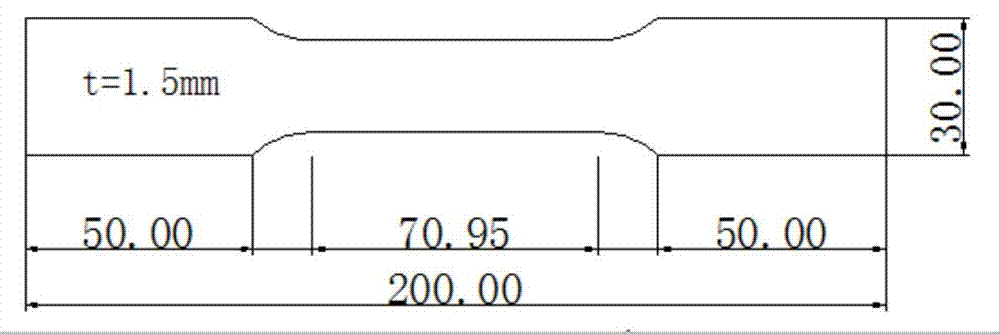

[0033] The technological process of the C-shaped open cylindrical shell with self-resetting function mainly includes: mechanical processing technology and heat treatment technology. refer to figure 1 , the specific production process is, steel plate rolling or mold casting → drilling after forming → high temperature overheating → normalizing → low temperature tempering → high temperature overheating → quenching (oil cooling) → medium temperature tempering → natural cooling. The C-shaped shell member is made of manganese steel with grade 65, and the thickness of the steel plate is 1.5mm. Firstly, according to image 3 As shown, three corresponding tensile members are manufactured, and then the C-shaped shell is manufactured according to the following heat treatment process. The heat treatment process of the tensile member and the C-shaped shell is the same. Described technological process specifically comprises the following steps:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius of curvature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com