Preparation method of nanometer calcium hydroxide/hexagonal boron nitride nano-composite

A nano-composite material, hexagonal boron nitride technology, applied in nitrogen compounds, chemical instruments and methods, calcium/strontium/barium oxide/hydroxide, etc., can solve the problem of large calcium hydroxide particles and achieve difficult agglomeration , strong antioxidant, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

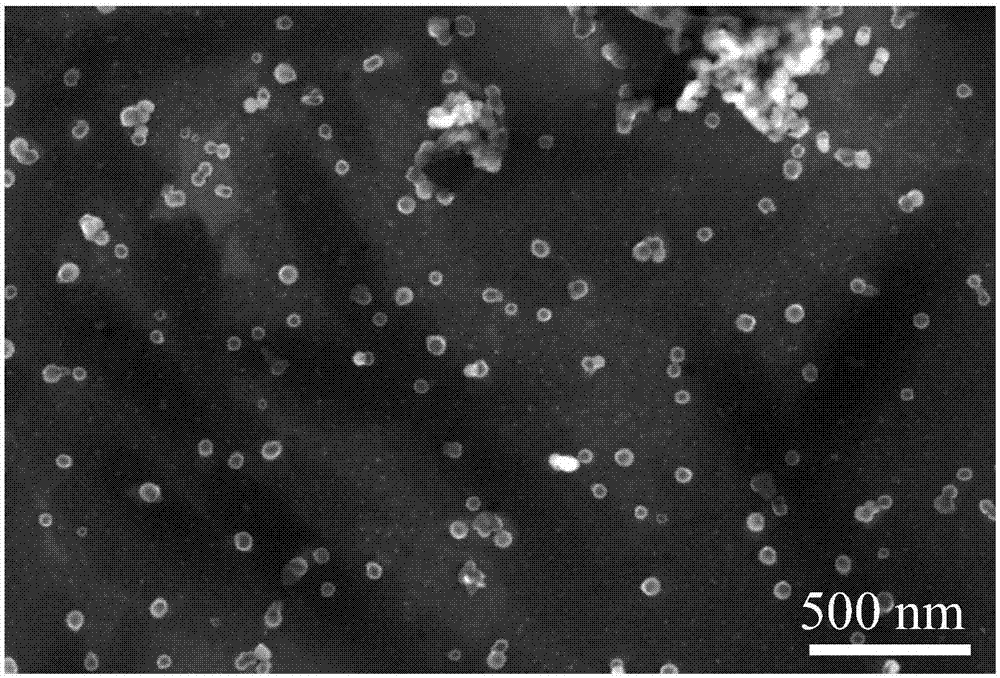

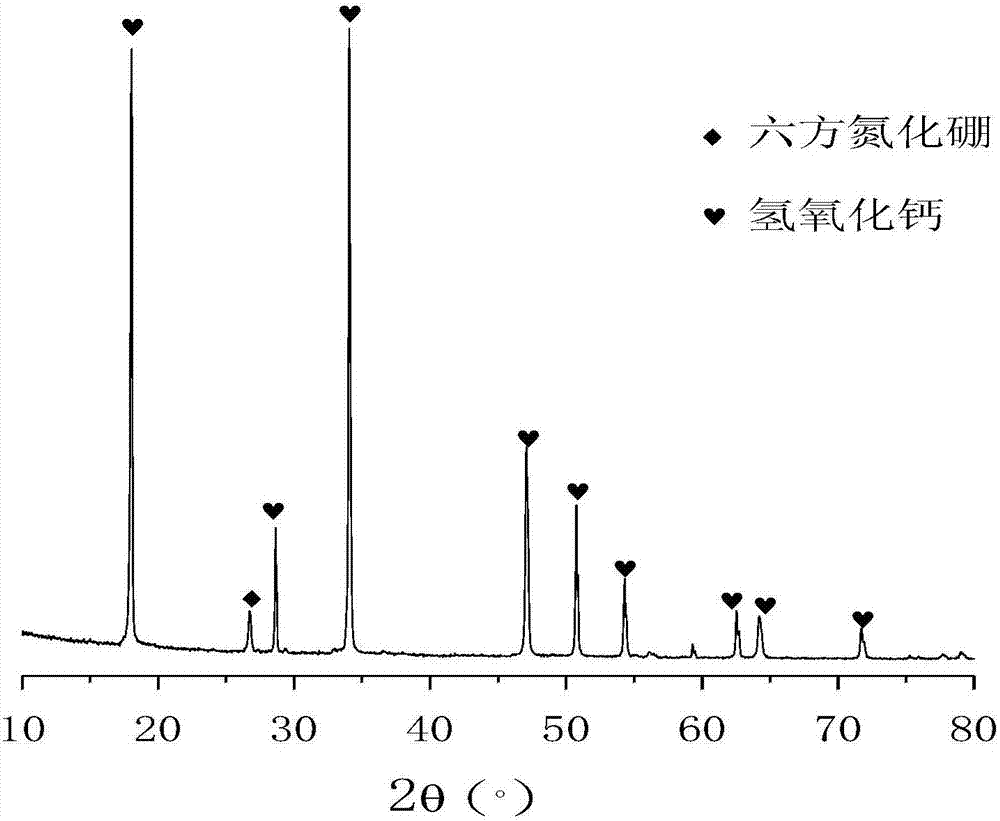

[0015] Commercially available hexagonal boron nitride powder was added to dimethylformamide to obtain a 2.9% hexagonal boron nitride solution and sonicated for 8 hours. Pour the sonicated solution into a centrifuge tube and centrifuge at 5000 rpm for 5 minutes. Pour the supernatant into a beaker and dry it at 80 degrees Celsius to obtain a powder.

[0016] Calcium chloride was dissolved in deionized water to obtain a 2.1% calcium chloride solution. The above-mentioned hexagonal boron nitride powder with a mass ratio of 0.013 to calcium chloride was added into the calcium chloride solution with stirring and heated to 60 degrees Celsius. Sodium hydroxide was dissolved in deionized water to obtain a 1.1% sodium hydroxide solution. When the solution of calcium chloride and powder is heated to 60 degrees Celsius, sodium hydroxide solution is added dropwise thereto at a speed of 0.5 ml / min, and the solution is continued to be incubated for 30 minutes after the addition is complete...

Embodiment 2

[0019] Add commercially available hexagonal boron nitride powder into dimethylformamide to obtain a 3.5% hexagonal boron nitride solution and sonicate for 10 h. Pour the sonicated solution into a centrifuge tube and centrifuge at 6000 rpm for 8 minutes. Pour the supernatant into a beaker and dry at 90°C to obtain a powder.

[0020] Calcium chloride was dissolved in deionized water to obtain a 3.3% calcium chloride solution. Said hexagonal boron nitride powder with a mass ratio of 0.014 to calcium chloride was added into the calcium chloride solution with stirring and heated to 70 degrees Celsius. Sodium hydroxide was dissolved in deionized water to obtain a 1.7% sodium hydroxide solution. When the solution of calcium chloride and powder is heated to 70 degrees Celsius, sodium hydroxide solution is added dropwise thereto at a speed of 0.9 ml / min, and the solution is continued to be incubated for 40 minutes after the dropwise addition. After the incubation period, it was cool...

Embodiment 3

[0022] Add commercially available hexagonal boron nitride powder into dimethylformamide to obtain a 4.3% hexagonal boron nitride solution and sonicate for 12 hours. Pour the sonicated solution into a centrifuge tube and centrifuge at 7000 rpm for 10 minutes. Pour the supernatant into a beaker and dry it at 100 degrees Celsius to obtain a powder.

[0023] Calcium chloride was dissolved in deionized water to obtain a 4.3% calcium chloride solution. The above-mentioned hexagonal boron nitride powder with a mass ratio of 0.015 to calcium chloride was added into the calcium chloride solution with stirring and heated to 90 degrees Celsius. Sodium hydroxide was dissolved in deionized water to obtain a 2.3% sodium hydroxide solution. When the solution of calcium chloride and powder is heated to 90 degrees Celsius, sodium hydroxide solution is added dropwise thereto at a speed of 1.1 ml / min, and after the dropwise addition, the temperature is continued for 60 minutes. After the incu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com