Fermentation treatment method for livestock breeding excrement

A treatment method and technology for livestock and poultry breeding, which is applied in the field of livestock and poultry breeding manure fermentation treatment, can solve the problems of increased treatment cost, low fermentation efficiency, and inability to realize circular economy, and achieve the effect of avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

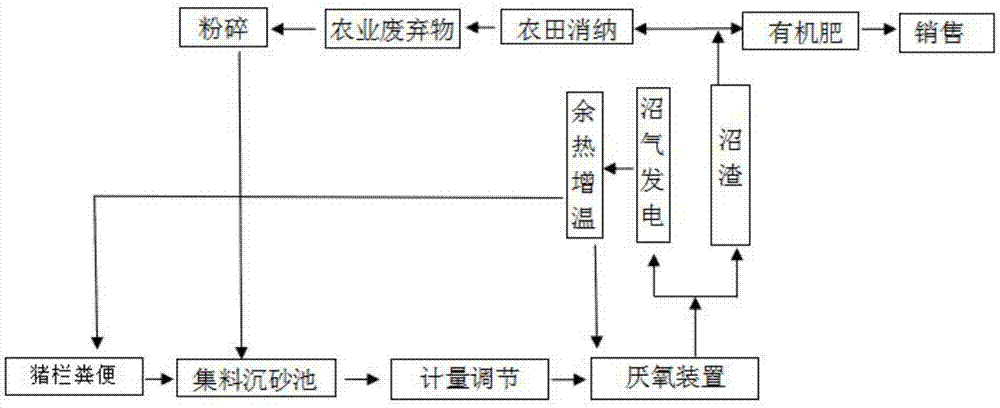

Image

Examples

Embodiment 1

[0021] A method for fermenting livestock and poultry breeding manure, comprising the following steps:

[0022] (1) Wash the feces of the pigsty with water to obtain primary biogas slurry, which automatically flows into the aggregate grit chamber through the sewage pipe network according to the water level drop;

[0023] (2) The primary biogas slurry flowing into the aggregate grit chamber is pumped into the anaerobic device through stirring and metering, and fermented in the anaerobic device. Before fermentation, the primary biogas slurry is subjected to ultrasonic treatment, and the ultrasonic treatment is divided into three stages , set the ultrasonic frequency at 25-35kHz in the first stage, set the ultrasonic frequency at 20-25kHz in the second stage, set the ultrasonic frequency at 15-20kHz in the third stage, control the fermentation time to 10 days, and control the fermentation temperature at 20°C. The positive and negative electrodes are inserted into the primary bioga...

Embodiment 2

[0030] A method for fermenting livestock and poultry breeding manure, comprising the following steps:

[0031] (1) Wash the feces of the pigsty with water to obtain primary biogas slurry, which automatically flows into the aggregate grit chamber through the sewage pipe network according to the water level drop;

[0032] (2) The primary biogas slurry flowing into the aggregate grit chamber is pumped into the anaerobic device through stirring and metering, and fermented in the anaerobic device. Before fermentation, the primary biogas slurry is subjected to ultrasonic treatment, and the ultrasonic treatment is divided into three stages , set the ultrasonic frequency at 25-35kHz in the first stage, set the ultrasonic frequency at 20-25kHz in the second stage, set the ultrasonic frequency at 15-20kHz in the third stage, control the fermentation time to 12.5 days, and control the fermentation temperature at 22.5°C. The positive and negative electrodes are inserted into the primary b...

Embodiment 3

[0039] A method for fermenting livestock and poultry breeding manure, comprising the following steps:

[0040] (1) Wash the feces of the pigsty with water to obtain primary biogas slurry, which automatically flows into the aggregate grit chamber through the sewage pipe network according to the water level drop;

[0041] (2) The primary biogas slurry flowing into the aggregate grit chamber is pumped into the anaerobic device through stirring and metering, and fermented in the anaerobic device. Before fermentation, the primary biogas slurry is subjected to ultrasonic treatment, and the ultrasonic treatment is divided into three stages , set the ultrasonic frequency at 25-35kHz in the first stage, set the ultrasonic frequency at 20-25kHz in the second stage, set the ultrasonic frequency at 15-20kHz in the third stage, control the fermentation time to 15 days, and control the fermentation temperature at 25°C. The positive and negative electrodes are inserted into the primary bioga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com