Preparation method for degradable plastic film by using discarded shrimp shells

A technology of plastic film and shrimp shells, which is applied in the field of preparing degradable plastics, can solve the problems of waste of resources, etc., and achieve the effects of reducing waste, superior physical properties, and wide sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

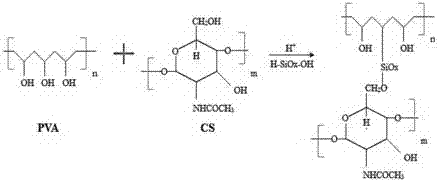

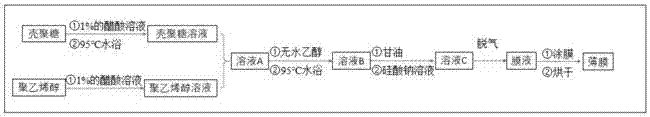

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] A method for preparing degradable plastics from discarded shrimp shells, comprising the following steps: (1) washing the shrimp shells, drying them, and grinding them into powder; (2) treating the shrimp shell powder by decalcification reaction to obtain astaxanthin Inorganic salt solution and filter residue A. The inorganic salt solution can be extracted to obtain astaxanthin, and the filter residue A can be dissolved in absolute ethanol and dehydrated to obtain red pigment and filter residue B; (3) The filter residue B obtained in step (2) is hydrolyzed by a weak base to form a carapace Factors and by-product amino acids. Under the action of deacetylation of concentrated alkali solution, chitin turns into chitosan, and the chitosan-based degradable plastic film is prepared by "casting film forming method". The specific production process is as follows:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com