Inorganic-organic composite flexible high-k thin film and preparing method thereof

A composite flexible and high dielectric technology, applied in the field of dielectric materials, can solve the problems of high dielectric loss, high brittleness and low breakdown voltage of pure inorganic CCTO films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing an inorganic-organic composite flexible high-dielectric film according to an embodiment of the present invention includes the following steps S1-S2.

[0029] Step S1: mixing the polyurethane elastomer with calcium copper titanate powder, vulcanizing agent and coupling agent to obtain composite raw rubber.

[0030] CCTO has an ultra-high dielectric constant (~10 4 ), and its dielectric constant has good frequency stability and temperature stability. Polyurethane elastomers have good adhesion, wide temperature resistance (-50 ° C ~ 150 ° C), excellent processing performance, low processing temperature, low dielectric loss, excellent insulation, flexibility and high Breakdown voltage, but its dielectric constant is usually low, it is difficult to meet the performance requirements of microelectronic components. Therefore, this application selects polyurethane elastomer and copper calcium titanate powder to form an inorganic-organic composite film af...

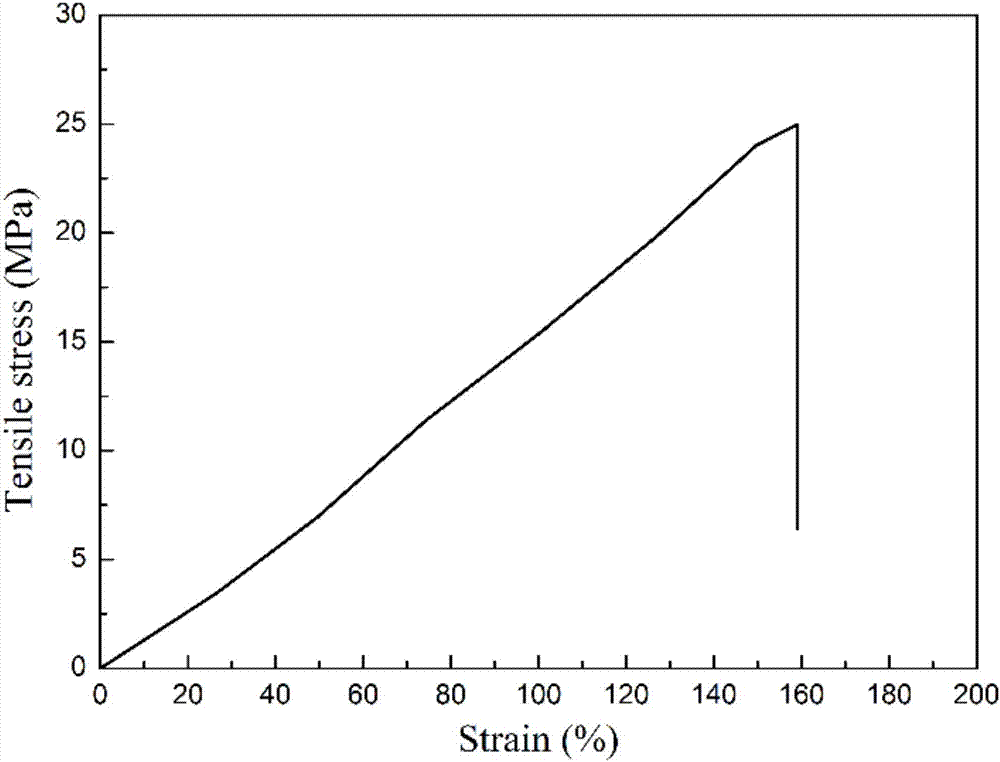

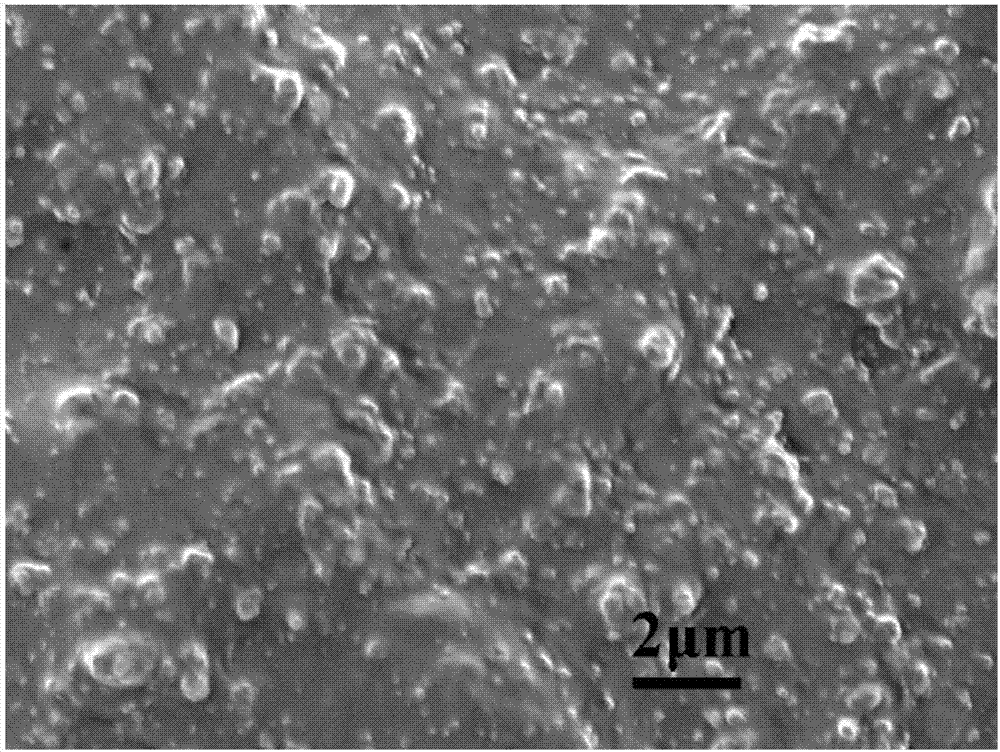

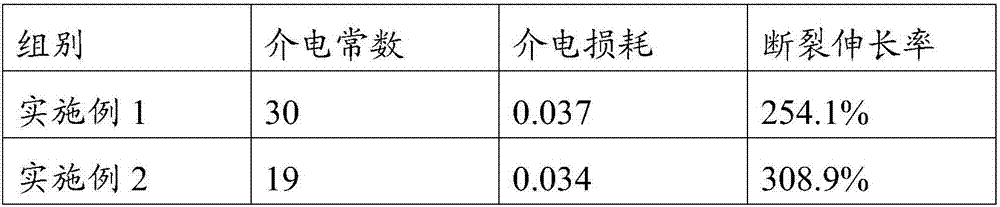

Embodiment 1

[0061] Add 10.11g of calcium carbonate powder, 24.10g of copper oxide powder, 32.27g of titanium dioxide powder, 190mL of absolute ethanol, and 266g of zirconia grinding balls into the grinding tank, and ball mill in a planetary ball mill at a speed of 200rpm for 1.5h, and then add 199g of NaCl to Continue ball milling at a speed of 200rpm for 1.5h to obtain a mixed slurry; place the above mixed slurry in a drying chamber at 75°C to dry, put it into an alumina crucible, and then place it in a high-temperature furnace and roast it at 850°C for 2h to obtain a salt-containing CCTO intermediate powder material. The above salt-containing CCTO intermediate powder was repeatedly washed with deionization at 85°C until no obvious white precipitate was observed in the supernatant liquid detected with silver nitrate solution, and the CCTO slurry obtained after washing was dried to obtain CCTO powder.

[0062] Take 58.88g of CCTO powder synthesized above, 30.00g of polyurethane elastomer,...

Embodiment 2

[0064] Add 10.11g of calcium carbonate powder, 24.10g of copper oxide powder, 32.27g of titanium dioxide powder, 190mL of absolute ethanol, and 266g of zirconia grinding balls into the grinding jar, mill in a planetary ball mill at a speed of 160rpm for 6 hours, then add 199g of KCl at a speed of 160rpm Continue ball milling for 3 hours to obtain a mixed slurry; place the above mixed slurry in a drying chamber at 75°C, dry it, put it into an alumina crucible, and then place it in a high-temperature furnace and bake it at 750°C for 5 hours to obtain a salt-containing CCTO intermediate powder. The above salt-containing CCTO intermediate powder was repeatedly washed with deionization at 75°C until no obvious white precipitate was observed in the supernatant liquid detected with silver nitrate solution, and the CCTO slurry obtained after washing was dried to obtain CCTO powder.

[0065] Take 34.35g of CCTO powder synthesized above, 30.00g of polyurethane elastomer, 0.90g of bis-2,5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com