High-transparency polyether type double-mirror TPU (thermoplastic polyurethane) thin film

A polyether-type, double-mirror technology, applied in the field of materials, can solve the problems of low pass rate, uneven film thickness, and low transparency of high-transparency polyether-type double-mirror TPU films, and achieve poor transparency, uniform thickness, and surface high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

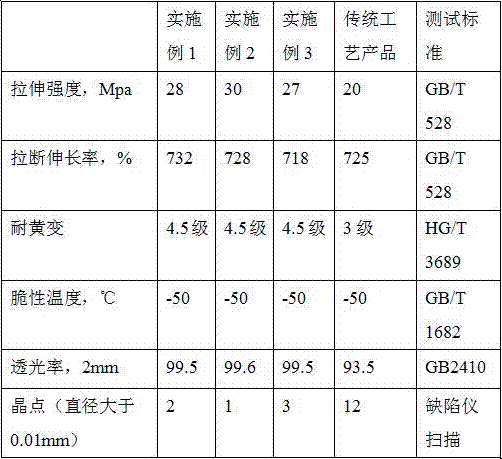

Examples

Embodiment 1

[0025] The highly transparent polyether type double-mirror TPU film is prepared according to the following formula proportions, requirements of each component and process method.

[0026] TPU resin: 100 parts;

[0027] Antioxidant: 0.1 part;

[0028] Light stabilizer: 1.8 parts;

[0029] Processing lubricant: 0.01 parts.

[0030] The TPU resin is a polyether-type thermoplastic polyurethane elastomer, the molecular weight of the soft segment PTMEG used in its synthesis is 1100-1200, the hydroxyl value is 110-115 (mg KOH / g), the Shore hardness is 80A-95A, and the weight-average molecular weight is 100,000~110,000, the molecular weight distribution is 2.0~2.5;

[0031] The antioxidant is triethylene glycol bis-[3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate] (antioxidant 245) and 1,3,5-tri (4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl) 1,3,5-triazine-2,4,6-(1H,3H,5H)-trione (antioxidant 1790) a compound system mixed at a mass ratio of 1:1.2;

[0032] The light stabilizer ...

Embodiment 2

[0039] The highly transparent polyether type double-mirror TPU film is prepared according to the following formula proportions, requirements of each component and process method.

[0040] TPU resin: 100 parts;

[0041] Antioxidant: 0.5 parts;

[0042] Light stabilizer: 0.5 parts;

[0043] Processing lubricant: 0.03 parts.

[0044] The TPU resin is a polyether-type thermoplastic polyurethane elastomer, the molecular weight of the soft segment PTMEG used in its synthesis is 1100-1200, the hydroxyl value is 110-115 (mg KOH / g), the Shore hardness is 80A-95A, and the weight-average molecular weight is 100,000~110,000, the molecular weight distribution is 2.0~2.5;

[0045] The antioxidant is triethylene glycol bis-[3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate] (antioxidant 245) and 1,3,5-tri (4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl) 1,3,5-triazine-2,4,6-(1H,3H,5H)-trione (antioxidant 1790) a compound system mixed at a mass ratio of 1:1.2;

[0046] The light stabilizer...

Embodiment 3

[0053] The highly transparent polyether type double-mirror TPU film is prepared according to the following formula proportions, requirements of each component and process method.

[0054] TPU resin: 100 parts;

[0055] Antioxidant: 0.8 parts;

[0056] Light stabilizer: 0.1 part;

[0057] Processing lubricant: 0.05 parts.

[0058] The TPU resin is a polyether-type thermoplastic polyurethane elastomer, the molecular weight of the soft segment PTMEG used in its synthesis is 1100-1200, the hydroxyl value is 110-115 (mg KOH / g), the Shore hardness is 80A-95A, and the weight-average molecular weight is 100,000~110,000, the molecular weight distribution is 2.0~2.5;

[0059] The antioxidant is triethylene glycol bis-[3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate] (antioxidant 245) and 1,3,5-tri (4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl) 1,3,5-triazine-2,4,6-(1H,3H,5H)-trione (antioxidant 1790) a compound system mixed at a mass ratio of 1:1.2;

[0060] The light stabilizer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com