Method for preparing high-strength heat-and-humidity resistant anti-reflection carbon silicon oxygen phosphorus composite coating

A technology of anti-reflection and anti-reflection, composite coating, applied in the direction of coating, can solve the problems of anti-reflection and anti-reflection performance easily affected by moisture, the coating is not resistant to humidity and heat strength, affecting the anti-reflection effect of the coating, etc. Achieve the effect of excellent anti-reflection and anti-reflection performance, good durability and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Mix ethyl orthosilicate, methyltrimethoxysilane, water and ethanol according to the molar ratio of 0.5~0.6:0.5~0.4:3~7:30~50 to obtain a mixed solution, add acid catalyst hydrochloric acid to adjust and mix The pH value of the solution is 1 to 3, then add 2 to 4 wt% of the surfactant cetyltrimethylammonium bromide and 1.5 to 3.5 wt% phosphoric acid in the total amount of the mixed solution, and stir at room temperature for 12 hours to obtain carbon Silicon oxyphosphorus composite sol solution.

[0033] 2) Coating the carbon-silicon-oxygen-phosphorus composite sol solution prepared in step 1) on a common glass substrate to prepare a coating. The coating method is spin coating, pulling, spray coating or roll coating.

[0034]3) Keep the coating prepared in step 2) at 200-400 degrees Celsius for 20-1000 minutes, then anneal at 600-750 degrees Celsius for 1-5 minutes, and then in a mixture of water and ethanol with a volume ratio of 2:1 A high-strength heat-resistant, ...

Embodiment 2

[0040] Same as Example 1, except that ethyl orthosilicate, methyltrimethoxysilane, water, and ethanol are mixed evenly in a molar ratio of 0.2-0.4:0.8-0.6:3-7:30-50.

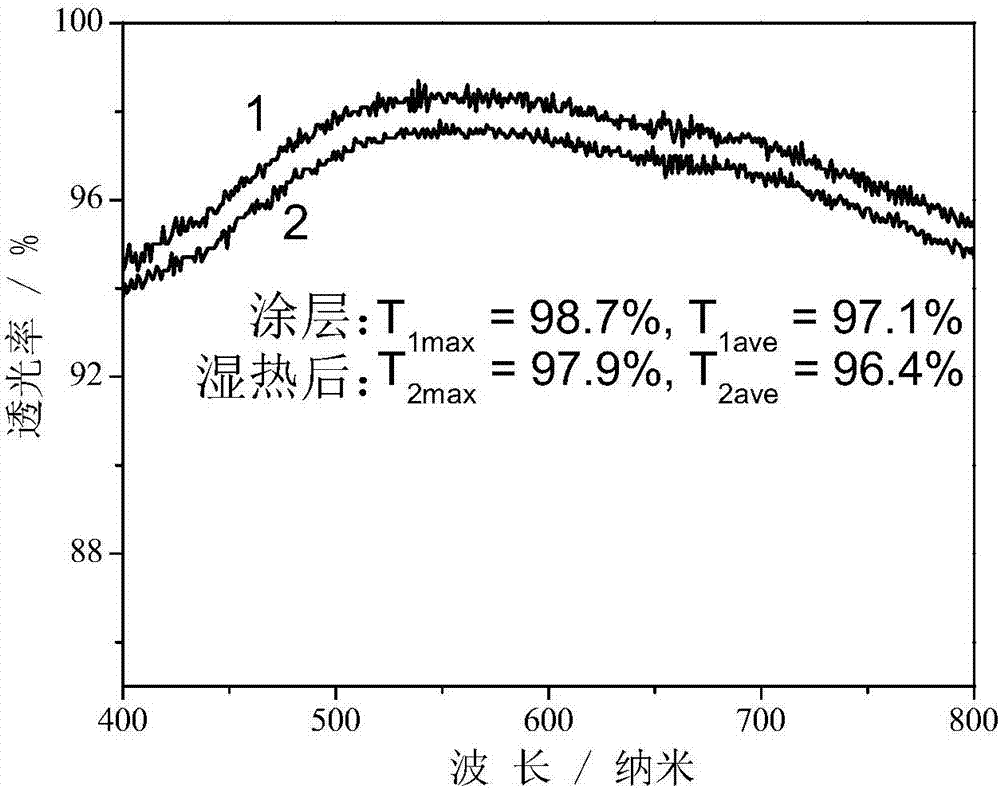

[0041] Light transmittance test: test the transmittance spectrum of the substrate with the above-mentioned coating with an ultraviolet-visible spectrometer, and the results are as follows image 3 Shown at midline 1. image 3 The middle line 1 is the transmission spectrum of the prepared sample. The maximum light transmittance of the coated substrate is 98.7%, and the average light transmittance in the wavelength range of 400-800nm is 97.1%, which shows that the coating has excellent anti-reflection and anti-reflection effects.

[0042] Humidity and heat resistance test: place the high-strength dampness and heat resistance antireflection and antireflection carbon silicon oxygen phosphorus composite coating prepared in this embodiment in saturated water vapor at 100 degrees Celsius for 12 hours, and measure th...

Embodiment 3

[0049] Same as Example 1, except that 1 wt% of surfactant cetyltrimethylammonium bromide was added at the end. The coating still has anti-reflection and anti-reflection, high strength, and heat and humidity resistance properties similar to those of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com