Waterborne anticorrosive coating and preparation method thereof

A water-based technology for anti-corrosion coatings, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of only having film-forming functions, only having weather resistance, and single functions of water-based resins, and achieves mature reaction methods, Suitable for large-scale production and remarkable technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

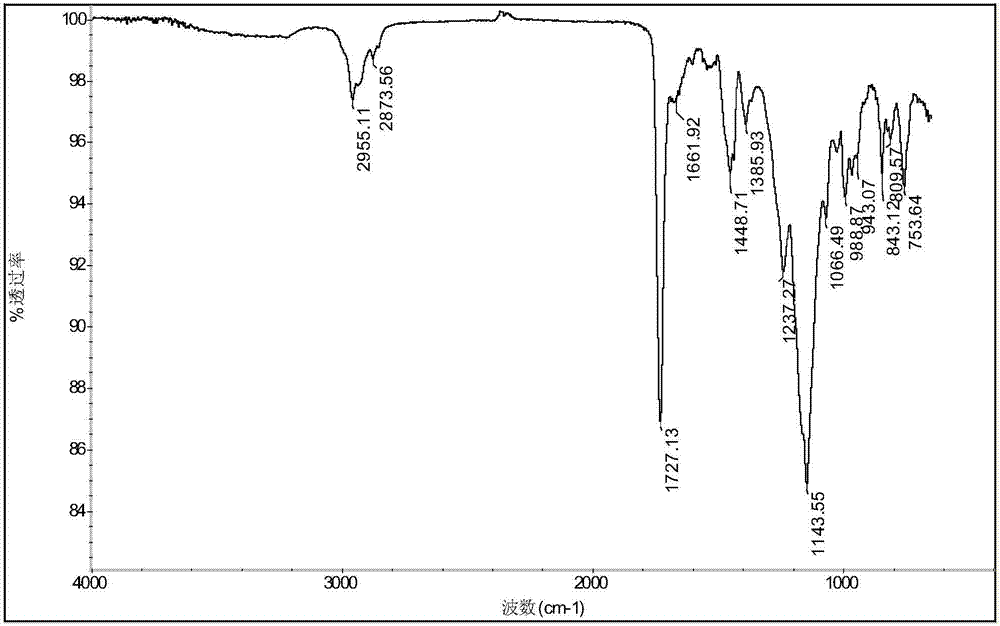

Image

Examples

Embodiment 1

[0088] A water-based anti-corrosion coating, calculated in parts by weight, its raw material composition and content are as follows:

[0089] Hydrophilic modified aliphatic polyisocyanate curing agent 10 parts

[0090] Long-lasting water-based resin 60 parts

[0091] Leveling agent 0.05 parts

[0092] 1 part wetting agent

[0093] 1 part thickener

[0094] 0.2 parts of defoamer

[0095] Coalescing aid 2 parts

[0096] Corrosion inhibitor 20 parts

[0097] 15 parts of pigments and fillers

[0098] Catalyst 0.02 parts

[0099] 20 parts deionized water

[0100] Wherein said hydrophilic modified aliphatic polyisocyanate curing agent is Bayhydur XP 2655 of German Bayer Company;

[0101] Described leveling agent is BYK 346 of BYK company;

[0102] Described wetting agent is NP-100 of U.S. Dow Company;

[0103] Described thickener is RM 825 of Rohm and Haas Co., Ltd.;

[0104] Described defoamer is the Nopco NXZ of German Henkel Company;

[0105] Described film-forming a...

Embodiment 2

[0123] A water-based anti-corrosion coating, calculated in parts by weight, its raw material composition and content are as follows:

[0124] 40 parts of hydrophilic modified aliphatic polyisocyanate curing agent

[0125] Long-lasting water-based resin 70 parts

[0126] Leveling agent 0.1 parts

[0127] Wetting agent 10 parts

[0128] thickener 3 parts

[0129] 1 part defoamer

[0130] Catalyst 1.0 parts

[0131] Corrosion inhibitor 30 parts

[0132] 30 parts of pigments and fillers

[0133] Coalescing aid 5 parts

[0134] 40 parts deionized water

[0135] Wherein said hydrophilic modified aliphatic polyisocyanate curing agent is Bayhydur XP 2655 of German Bayer Company;

[0136] Described leveling agent is BYK 346 of BYK company;

[0137] Described wetting agent is NP-100 of U.S. Dow Company;

[0138] Described thickener is RM 825 of Rohm and Haas Co., Ltd.;

[0139] Described defoamer is the Nopco NXZ of German Henkel Company;

[0140] The corrosion inhibitor is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com