Proportion-adjustable CoNi/porous carbon microwave absorbent and preparation method thereof

A technology of microwave absorbent and porous carbon, which is applied in the preparation of CoNi/porous carbon microwave absorbent, and the field of CoNi/porous carbon microwave absorbent, can solve problems such as unfavorable industrial production, complex multi-step processing process, etc., and achieve excellent electromagnetic absorption. The effect of wave performance, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the CoNi / porous carbon microwave absorber with adjustable ratio of the present invention comprises the following steps:

[0030] Step 1, weigh 6mmol of cobalt nitrate and 6mmol of nickel nitrate and dissolve them in 100mL of deionized water respectively, then configure 20mL of sodium alginate sol with a mass fraction of 2.0wt%, and slowly pour the dissolved cobalt nitrate and nickel nitrate solutions into the seaweed Sodium acid sol, stirring continuously at room temperature for 24 hours, after the stirring, the initial product after the reaction was washed with water and absolute ethanol three times respectively, and dried in a vacuum drying oven at 60°C for 24 hours after cleaning;

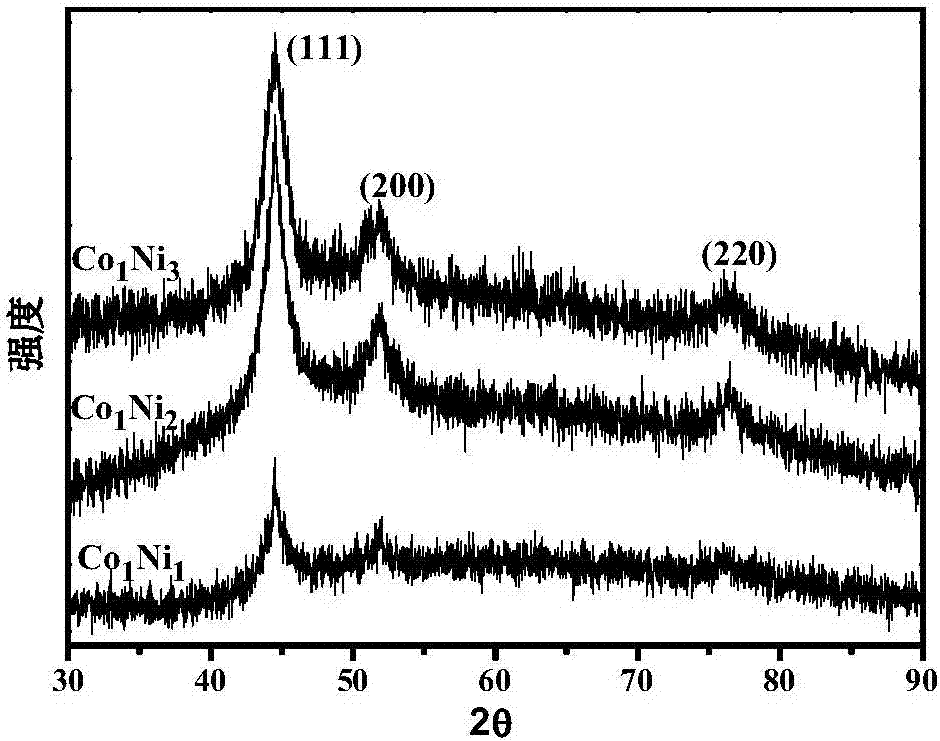

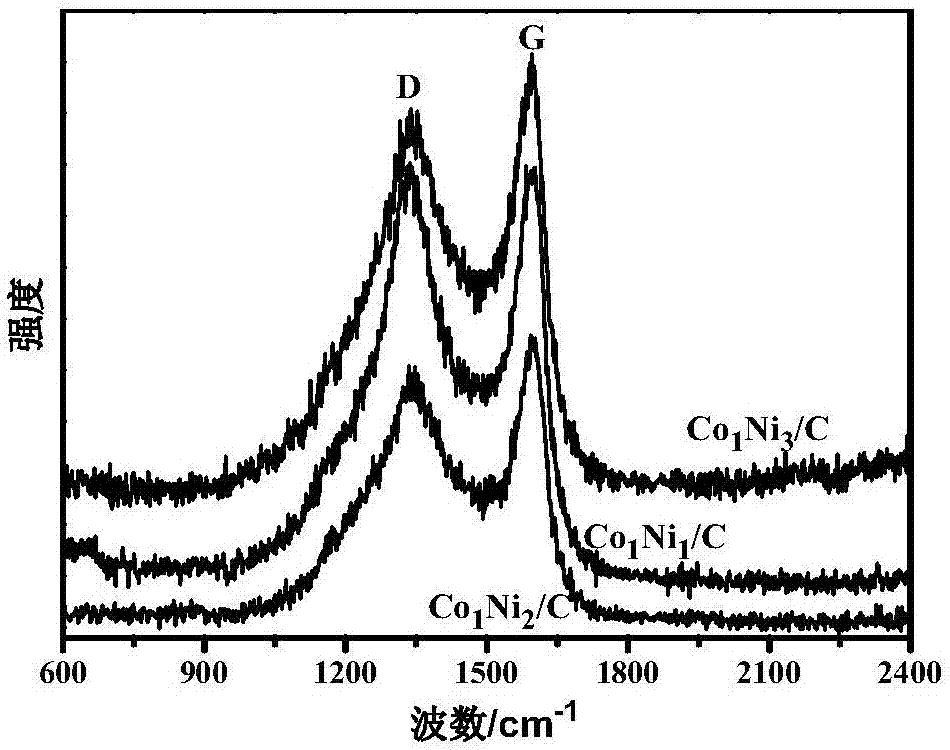

[0031] Step 2, calcining the initial product obtained in step 1 at high temperature in a nitrogen atmosphere, the heating rate is 1°C / min, the calcination temperature is 600°C, and the holding time is 6h. The obtained product is marked as Co 1 Ni 1 / C.

Embodiment 2

[0033] The preparation method of the CoNi / porous carbon microwave absorber with adjustable ratio of the present invention comprises the following steps:

[0034] Step 1, weigh 4mmol of cobalt nitrate and 8mmol of nickel nitrate and dissolve them in 100mL of deionized water respectively, then configure 20mL of sodium alginate sol with a mass fraction of 2.0wt%, and slowly pour the dissolved cobalt nitrate and nickel nitrate solutions into the seaweed Sodium acid sol, stirring continuously at room temperature for 24 hours, after the stirring, the initial product after the reaction was washed with water and absolute ethanol three times respectively, and dried in a vacuum drying oven at 60°C for 24 hours after cleaning;

[0035] Step 2, calcining the initial product obtained in step 1 at high temperature in a nitrogen atmosphere, the heating rate is 1°C / min, the calcination temperature is 600°C, and the holding time is 6h. The obtained product is marked as Co 1 Ni 2 / C.

Embodiment 3

[0037] The preparation method of the CoNi / porous carbon microwave absorber with adjustable ratio of the present invention comprises the following steps:

[0038] Step 1, weigh 3mmol of cobalt nitrate and 9mmol of nickel nitrate and dissolve them in 100mL of deionized water respectively, then configure 20mL of sodium alginate sol with a mass fraction of 2.0wt%, and slowly pour the dissolved cobalt nitrate and nickel nitrate solutions into the seaweed Sodium acid sol, stirring continuously at room temperature for 24 hours, after the stirring, the initial product after the reaction was washed with water and absolute ethanol three times respectively, and dried in a vacuum drying oven at 60°C for 24 hours after cleaning;

[0039] Step 2, calcining the initial product obtained in step 1 at high temperature in a nitrogen atmosphere, the heating rate is 1°C / min, the calcination temperature is 600°C, and the holding time is 6h. The obtained product is marked as Co 1 Ni 3 / C.

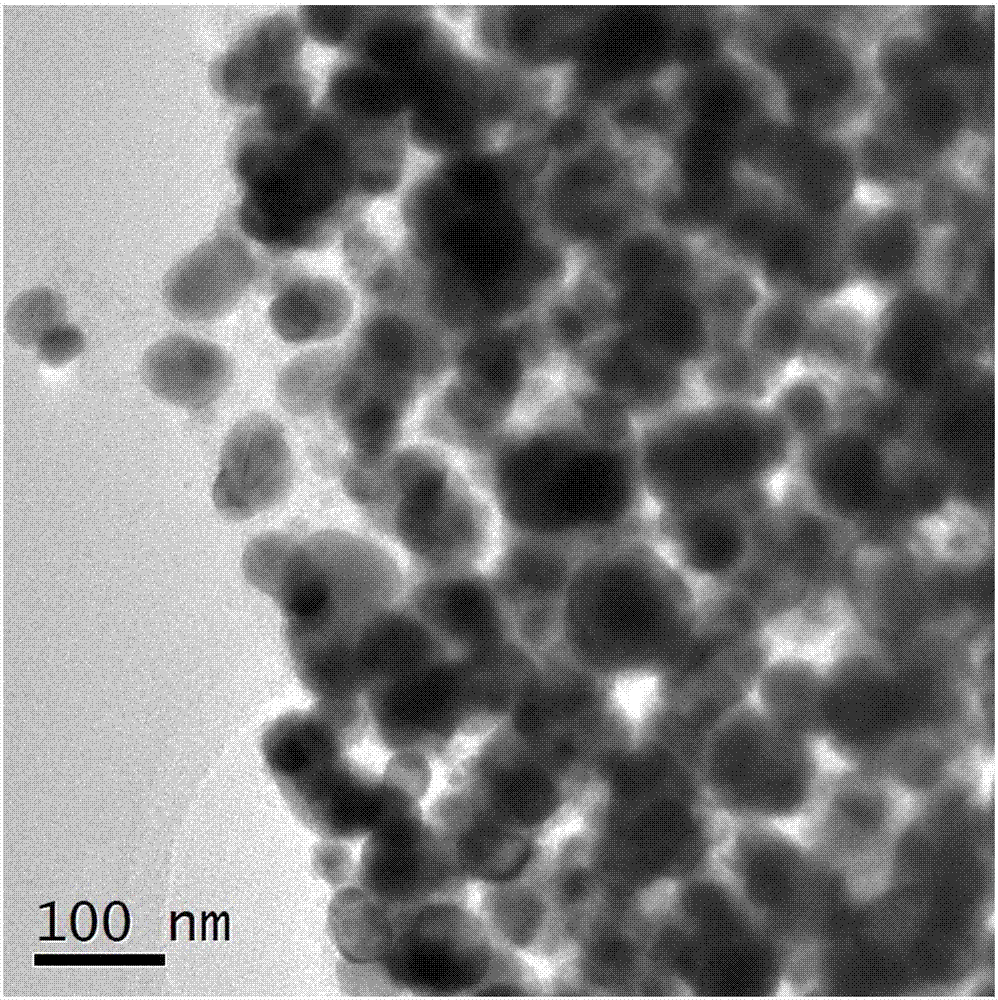

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com