High-performance corrosion-resistant economic composite steel coiled tubing and manufacturing method thereof

A composite steel material and manufacturing method technology, applied in the direction of rigid pipe, pipe, pipeline protection, etc., can solve the problem that the coiled tubing cannot fully meet the economic, efficient, safe and reliable operation requirements, and the performance cannot fully meet the field operation requirements of the coiled tubing. Unable to withstand pressure loads and other problems, to achieve the effect of solving insufficient corrosion resistance, good plasticity and toughness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

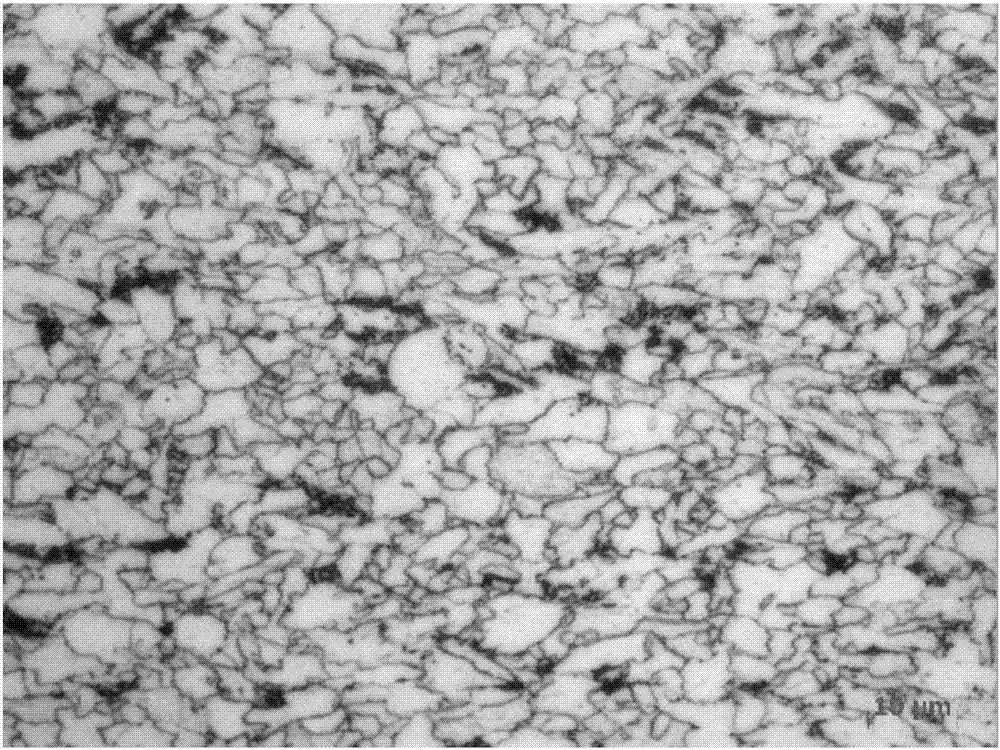

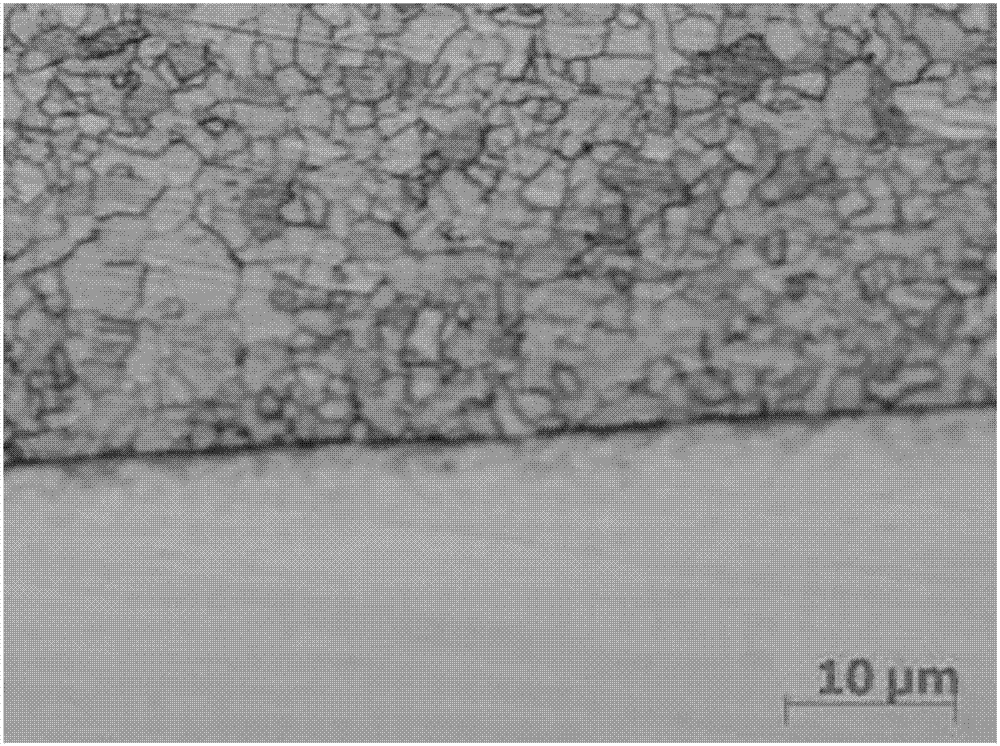

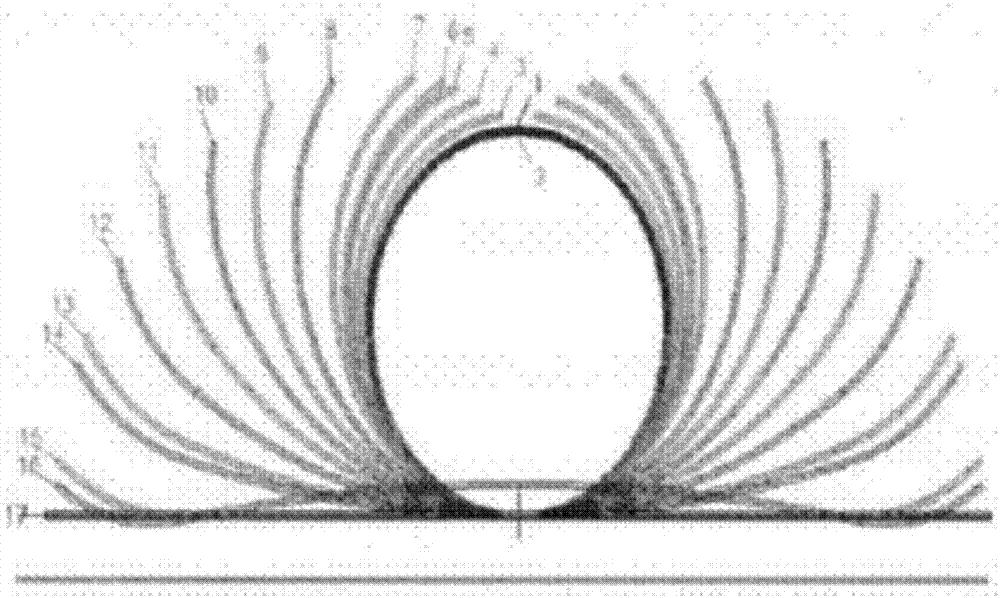

[0045] Please refer to Figure 1-3 As shown, a high-performance corrosion-resistant economical composite steel coiled tubing includes a base layer 1 and a composite layer 2, and the base layer 1 and the composite layer 2 are metallurgically combined; wherein the base layer 1 is a carbon steel or low alloy steel layer, The composite layer 2 is a corrosion-resistant alloy layer. The composite layer 2 is arranged on the inner or outer surface of the base layer 1 to form a single-layer composite coiled tubing. The composite layer 2 is arranged on the inner surface and the outer surface of the base layer 1 to form an inner and outer composite layer coiled tubing.

[0046] Each component and mass percentage in the base layer 1 are as follows:

[0047] C 0.06%-0.23%, Mn 0.5%-2.1%, P≤0.02%, S≤0.005%, Si 0.15%-0.5%, Cr 0.35%-1.6%, Mo 0.02%-0.3%, Ni 0.05%-0.97 %, Cu 0.1%-0.5%, Nb+Ti+V≤0.2%, Fe balance.

[0048] The composite layer 2 is an austenitic stainless steel layer, and the co...

Embodiment 1

[0070] A method for manufacturing high-performance corrosion-resistant economical composite steel coiled tubing. The coiled tubing includes an inner base layer and an outer layer composite tube of an outer composite layer. According to the chemical composition requirements of the coiled tubing base material, the coiled tubing is smelted in an electric furnace (EF), Ladle refining (LF) and vacuum degassing (VD) are used to smelt, precisely control the chemical composition of molten steel, reduce harmful non-metallic elements and inclusions, and carry out continuous production through mold electromagnetic stirring technology, mold non-sinusoidal vibration technology, and light reduction technology. Cast billets, through controlled rolling and controlled cooling technology, to obtain low-carbon low-alloy steel coils with excellent microstructure and grain size ASTM Grade12. According to mass percentage, its specific chemical composition is as follows: C 0.08%, Mn 0.75%, P 0.010%, ...

Embodiment 2

[0074] A method for manufacturing high-performance, corrosion-resistant and economical composite steel coiled tubing. The coiled tubing includes a base layer and an inner and outer layer composite tube of an inner and outer composite layer. According to the chemical composition requirements of the coiled tubing base material, the coiled tubing is smelted in an electric furnace (EF), ladle Refining (LF) and vacuum degassing (VD) smelting, precise control of the chemical composition of molten steel, reducing harmful non-metallic elements and inclusions, continuous casting through mold electromagnetic stirring technology, mold non-sinusoidal vibration technology, and light reduction technology After being formed into billets, low-carbon low-alloy steel coils with good microstructure and grain size of ASTM Grade13 are obtained through controlled rolling and controlled cooling technology. According to mass percentage, its specific chemical composition is as follows: C 0.12%, Mn 0.87...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com